Mobile advance supporting system and supporting method

A technology of advanced support and frame shifting, applied in mine roof support, earthwork drilling, mining equipment, etc., can solve the problems of roof safety hazards, long roof emptying time, and low operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

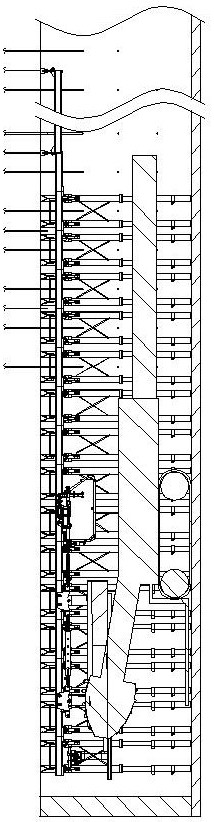

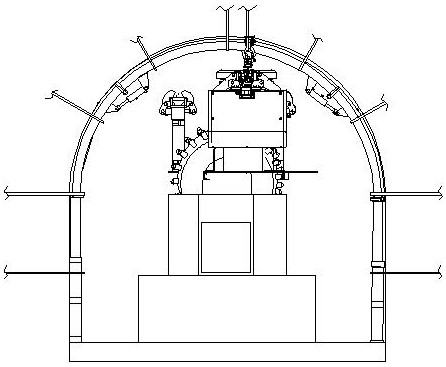

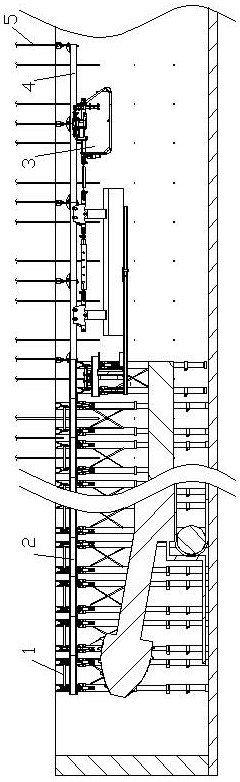

[0036] Such as Figure 1~4 A mobile advance support system is shown, including a moving frame unit 3 and a number of double support frames 1 sequentially arranged along the length direction of the roadway, each double support frame body forms a support section, and the rear of the support section is provided with The rear guide rail, and several suspenders 5 that are fixed on the top of the roadway, each suspender is arranged along the length direction of the roadway, and the rear guide rail 4 is installed at the lower end of the suspender 5. For ease of use, the rear guide rail of this embodiment includes several sections The track bodies arranged in sequence along the length direction of the roadway, the track body is hoisted at the lower end of the boom through the horizontal suspension shaft, and the horizontal suspensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com