Ball type anchor rod pre-tightening torque rapid installation device

An installation device and ball-type technology, applied in the installation of bolts, mining equipment, earth-moving drilling, etc., can solve the problems of inability to quantitatively and controllably apply torque, inability to fully exert the fastening function, and large instantaneous reaction force of workers, etc. Achieve the effect of increasing the effective support length, simple structure and improving installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

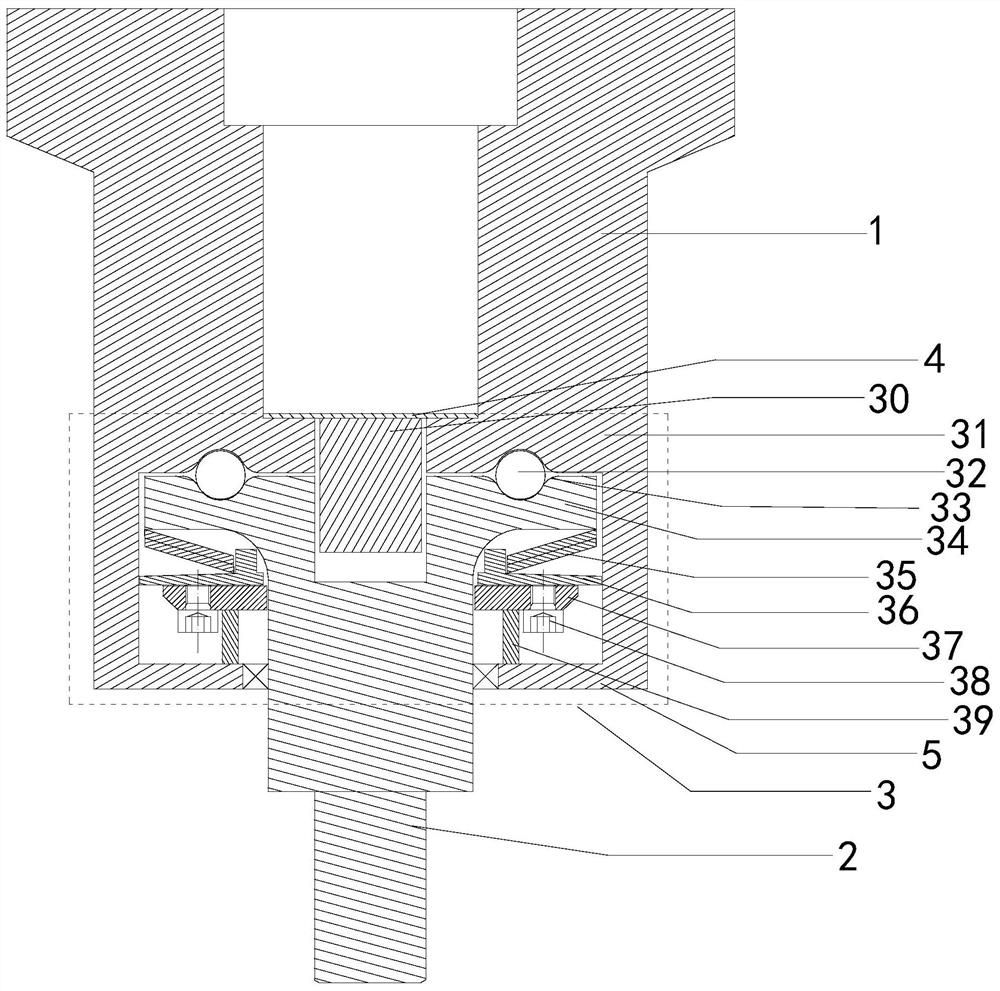

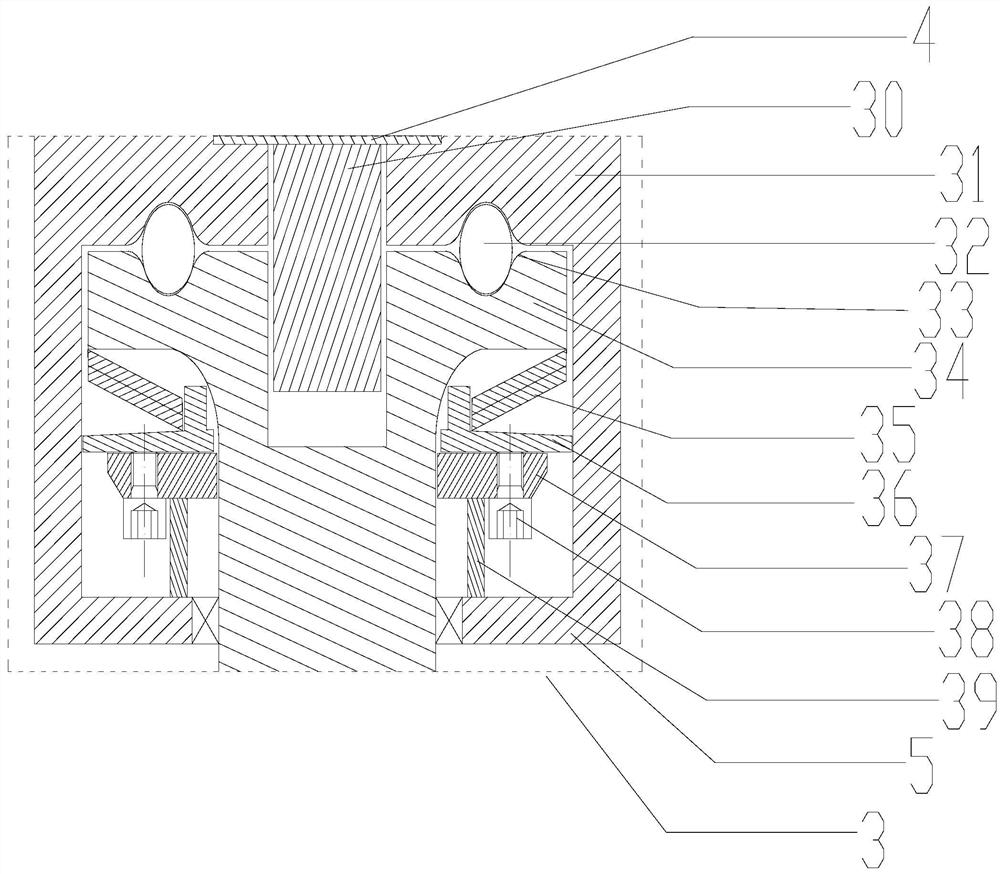

[0023] see Figure 1-2 : A kind of ball-type fixed pretightening torque fast installation device for anchor rods in this embodiment, sequentially includes an input unit 2, a torque control unit 3, an output unit 1, and a connection between the output unit 1 and the input unit 2 in the direction of torque transmission. The torque control unit 3 is fixedly connected between them; the torque control unit 3 adopts a steel ball and ball structure, and is used to apply a set torque to the anchor rod.

[0024] It should be noted that this embodiment divides the original installation tool simply used for anchor rod stirring resin coils into an output unit and an input unit, and then creatively designs a torque control unit between these two units; this embodiment The torsion force on the anchor rod is controlled by the torque control unit of the steel ball and ball structure, and the set torque is applied.

[0025] see figure 2 : In a specific example: the torque control unit 3 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com