Magnetizing and using method of polygonal magnetic steel

A polygonal, magnetizing direction technology, applied in the direction of magnetic objects, electrical components, circuits, etc., can solve the problems of large loss, high cost of magnetic steel production, limited magnetic field enhancement effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

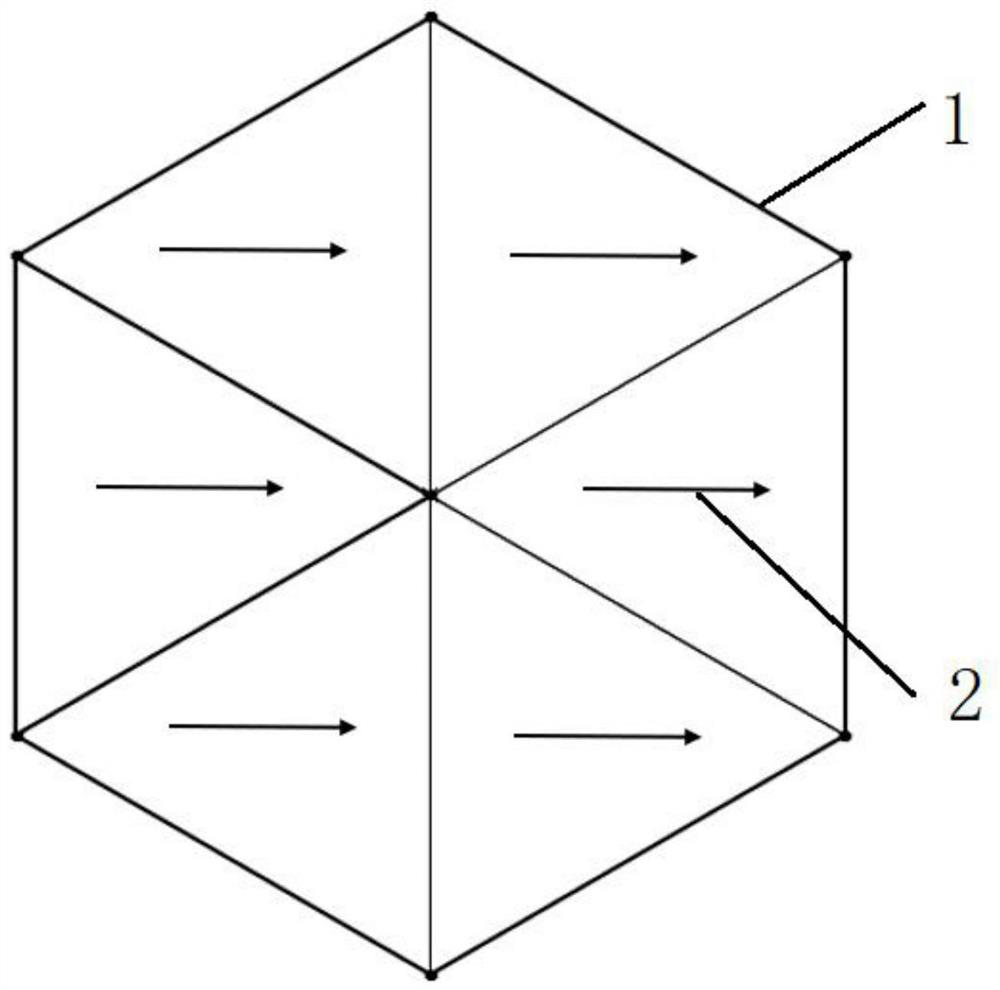

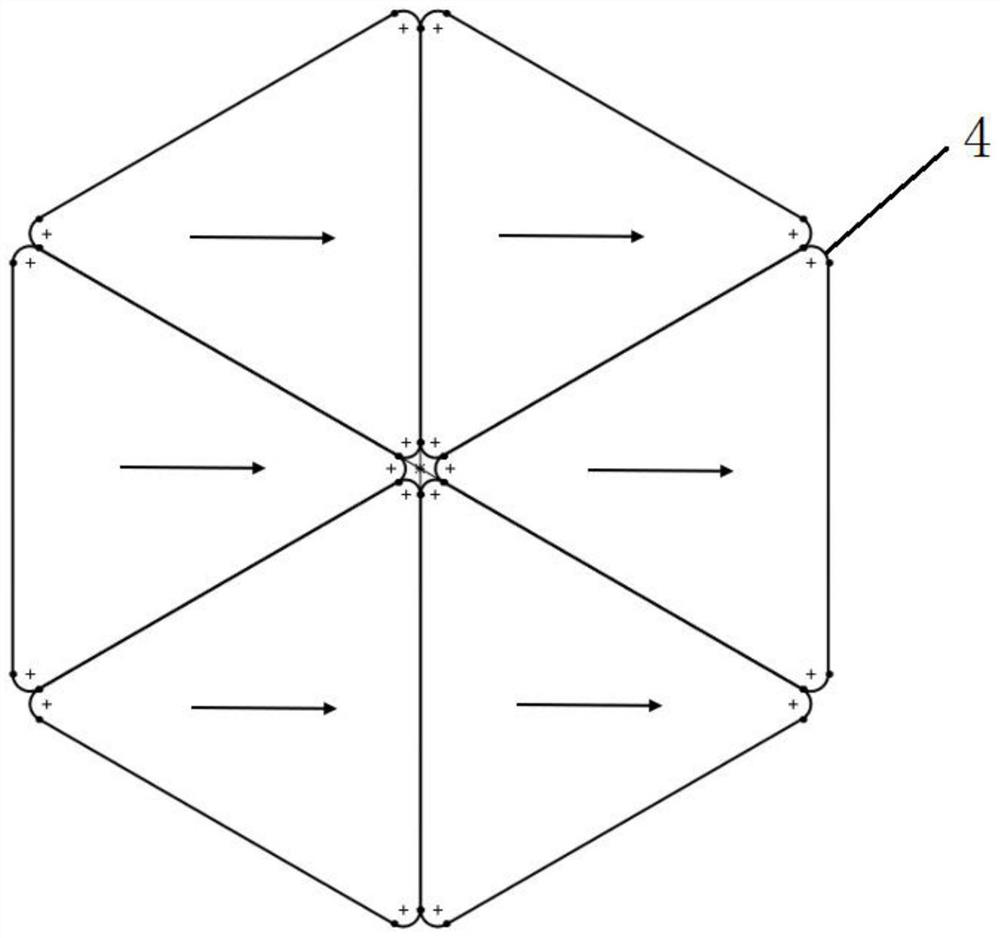

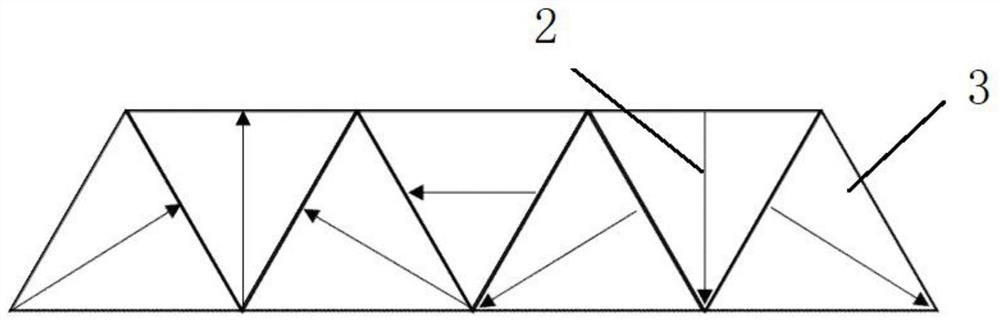

[0032] First, the raw materials are placed in a polygonal mold and sintered into a polygonal material. The polygonal material here is a regular polygon with N sides, and N is a natural number greater than or equal to 3; then, the polygonal material is fixed, and then the polygonal material is processed along the horizontal direction. Polygonal permanent magnets are obtained by unidirectional magnetization; then, the magnetized polygonal permanent magnets are mechanically cut to form multiple polygonal magnets with different magnetization directions and a certain angle between the magnetization direction and the horizontal. The steel is rotated at a certain angle and pieced together into a topological structure.

[0033] The selection of the polygonal material here is based on the topological structure of the polygonal magnetic steel obtained after subsequent cutting. For example, regular hexagons are easy to cut into equilateral triangles and isosceles trapezoidal structures. ...

Embodiment 2

[0036] The polygonal permanent magnet is obtained after the polygonal material is magnetized in the horizontal direction, and the polygonal permanent magnet is cut into the same polygon or two or more polygons of different shapes. The polygonal structure is triangular, quadrilateral, pentagonal or hexagonal.

[0037] Further, the triangle is a regular triangle or an equilateral triangle, the quadrilateral is a parallelogram, the pentagon is a regular pentagon, and the hexagon is a regular hexagon.

[0038] Further, the polygonal magnetic steel here preferably adopts regular triangles, regular pentagons and regular hexagons, and a special shape of hexagons can also be used. This special hexagon is evolved from a regular hexagon, and a A regular hexagon can be regarded as a hexagonal figure composed of three sets of parallel sides. Extend any set of parallel sides at the same distance. 1.5-3.5 times to form a new hexagonal figure.

[0039] In this embodiment, a regular hexagona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com