Capacitive coupling device and filter

A technology of capacitive coupling and connection position, which is applied in the field of communication, can solve the problems that the second harmonic is close to the passband of the filter and the influence of out-of-band suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

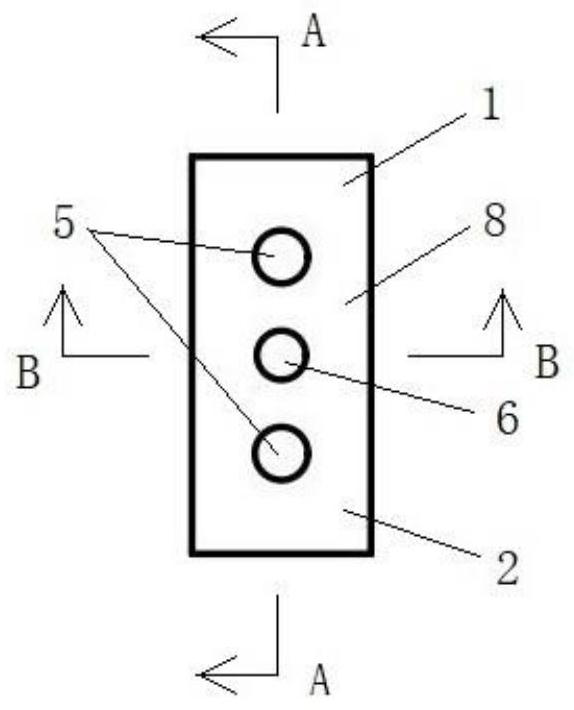

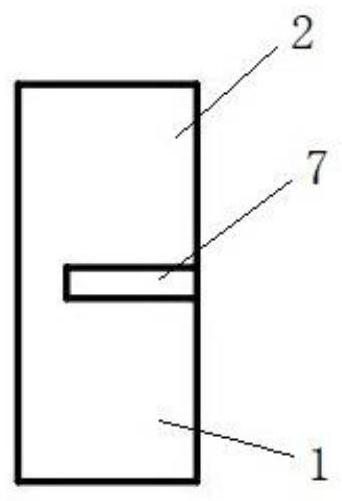

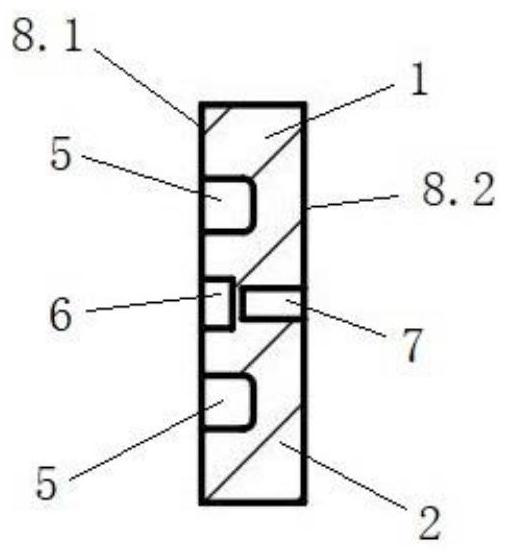

[0059] Such as Figure 1-5 As shown, this embodiment provides a capacitive coupling device, including a first dielectric resonator 1 and a second dielectric resonator 2 connected to each other, and the body surfaces of the first dielectric resonator 1 and the second dielectric resonator 2 8 are provided with a tuning hole 5, the tuning hole 5 is a blind hole, the surface of the first dielectric resonator 1 and the second dielectric resonator 2 are provided with a conductive layer, the first dielectric resonator 1 and the second dielectric resonator Negative coupling holes are provided between the resonators 2, and the negative coupling holes include longitudinal blind holes 6 and transverse blind grooves 7, the longitudinal blind holes 6 are cylindrical, that is, the cross section is circular; the transverse blind grooves are square grooves, and the transverse blind grooves The width of the blind groove 7 is smaller than the diameter of the longitudinal blind hole 6, the lengt...

Embodiment 2

[0061] Such as Figure 6-8 As shown, this embodiment provides a capacitive coupling device, which is basically similar in structure to the coupling device in Embodiment 1, the difference is that in this embodiment, the transverse blind groove 7 is located on the body surface 8 where the two dielectric resonators are connected. Where the front side 8.1 meets the body side 9, the width and length of the transverse blind groove 7 are greater than the diameter of the longitudinal blind hole 6, and the top of the longitudinal blind hole 6 runs through the bottom surface of the transverse blind groove and communicates with the transverse blind groove 7 .

Embodiment 3

[0063] Such as Figure 9-13 As shown, this embodiment provides a capacitive coupling device, including a first dielectric resonator 1, a second dielectric resonator 2, a third dielectric resonator 3 and a fourth dielectric resonator 4 connected to each other, the first dielectric resonator Positive coupling with a certain amount of coupling is generated between the device 1, the second dielectric resonator 2, the third dielectric resonator 3 and the fourth dielectric resonator 4 through the T-shaped coupling hole 10 provided in the center, and the first dielectric resonator 1. The body surfaces 8 of the second dielectric resonator 2, the third dielectric resonator 3 and the fourth dielectric resonator 4 are all provided with tuning holes 5, and the tuning holes 5 are blind holes. The third dielectric resonator 3 and the fourth dielectric resonator The body surface 8 of the resonator 4 is provided with input and output ports, and the end face of the input and output ports 11 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com