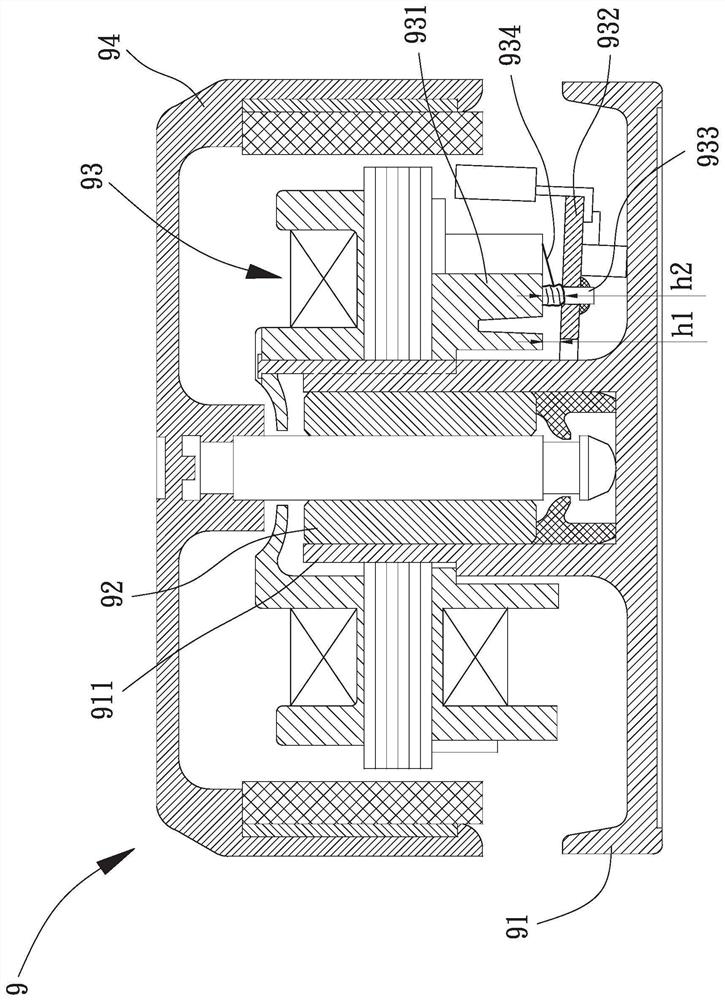

Motor stator manufacturing method and motor stator

A technology for a motor stator and a manufacturing method, which is applied to the motor parts manufacturing method and the field of motor parts, can solve the problems of difficulty in improving efficiency, high difficulty in welding operations, and large welding height h2, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

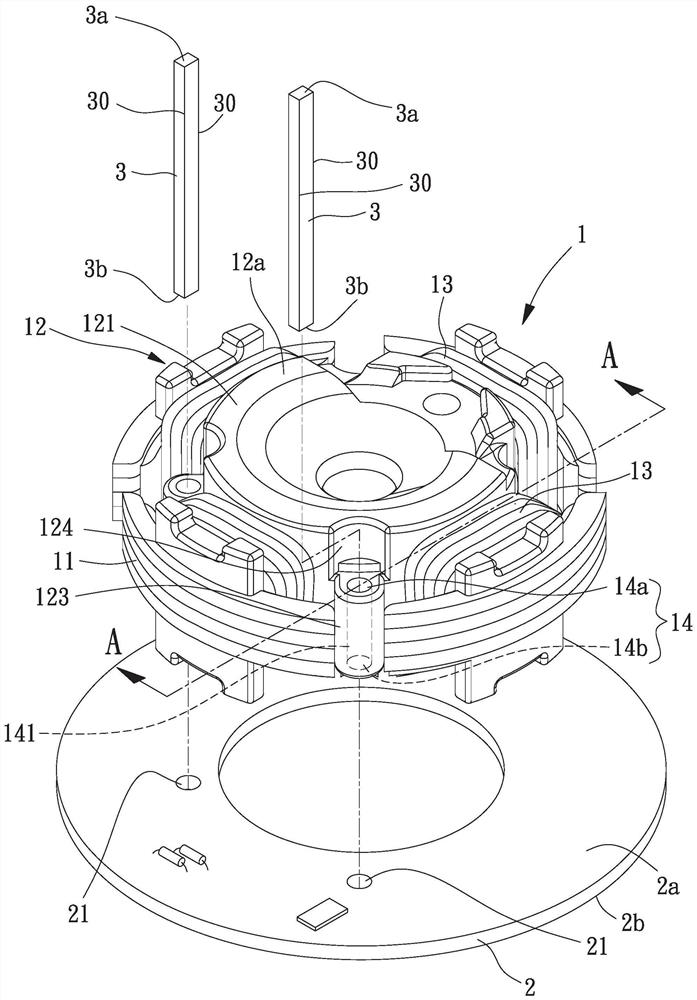

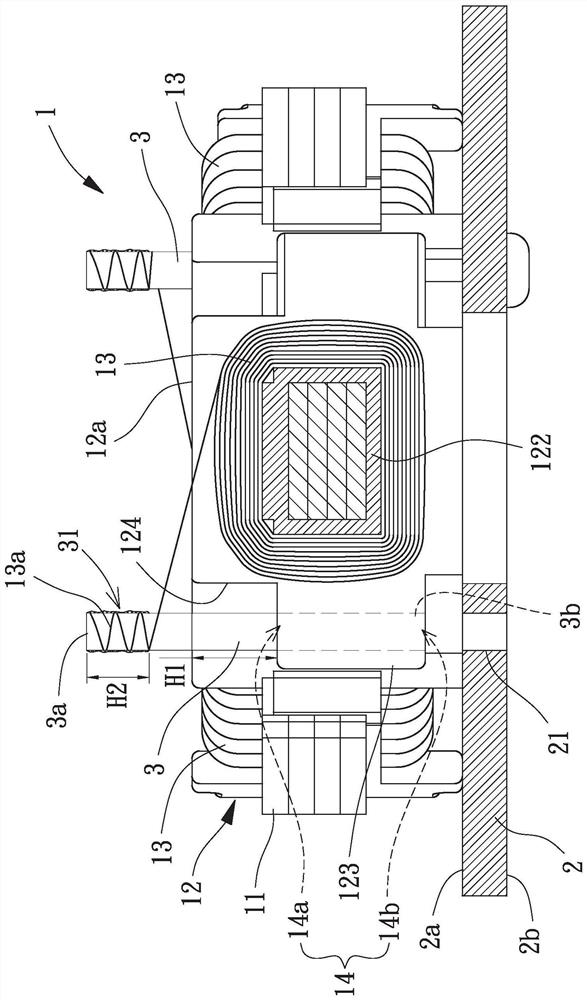

[0069] In order to make the above-mentioned and other objects, features and advantages of the present invention more obvious and understandable, the preferred embodiments of the present invention are listed below, together with the accompanying drawings, and are described in detail as follows:

[0070] Directionality or similar terms used throughout the invention, such as "front", "rear", "left", "right", "upper (top)", "lower (bottom)", "inner", "outer" , "side", etc., mainly refer to the directions of the drawings, and each direction or its approximate terms are only used to assist in explaining and understanding the various embodiments of the present invention, and are not intended to limit the present invention.

[0071] The elements and components described throughout the present invention use the quantifier "a" or "an" only for convenience and to provide the usual meaning of the scope of the present invention; in the present invention, it should be interpreted as includin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com