Processing equipment for inclined plane of forklift drive axle

A technology for processing equipment and drive axles, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of forklift drive axle processing shaking, processing instability, etc., to ensure positioning, improve processing efficiency, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

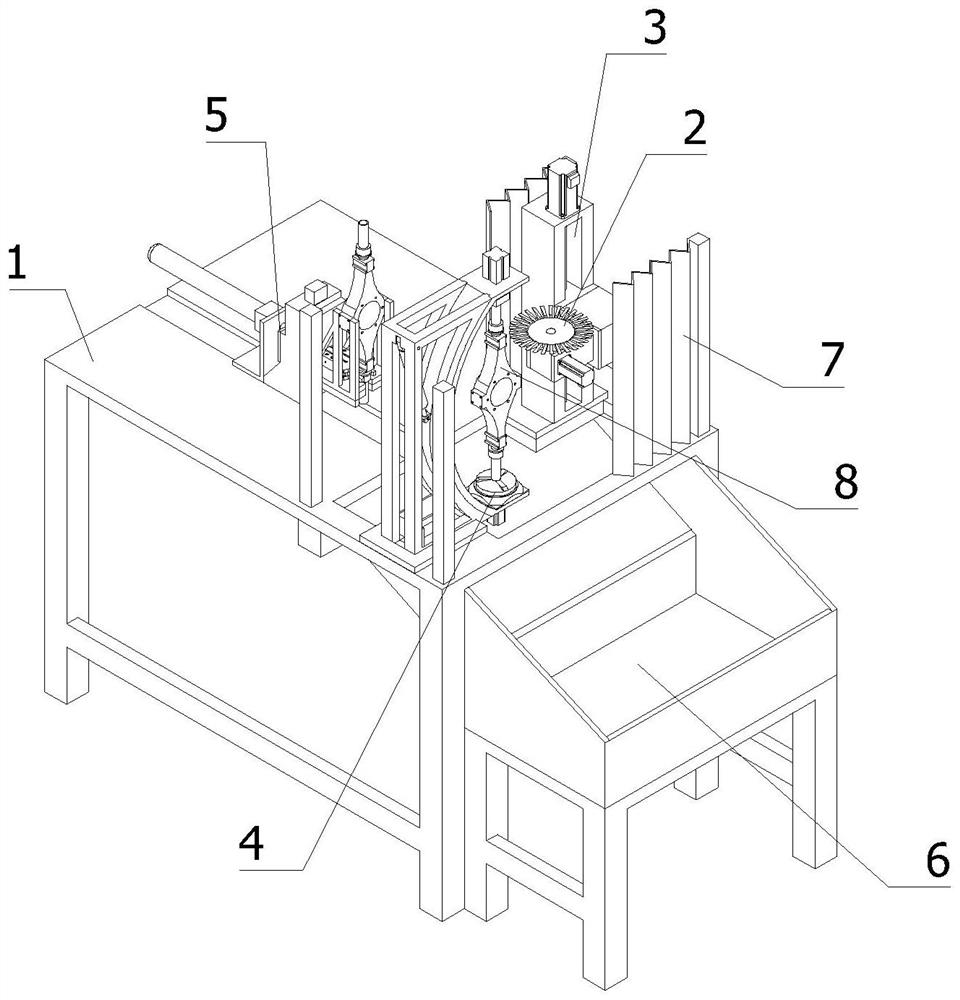

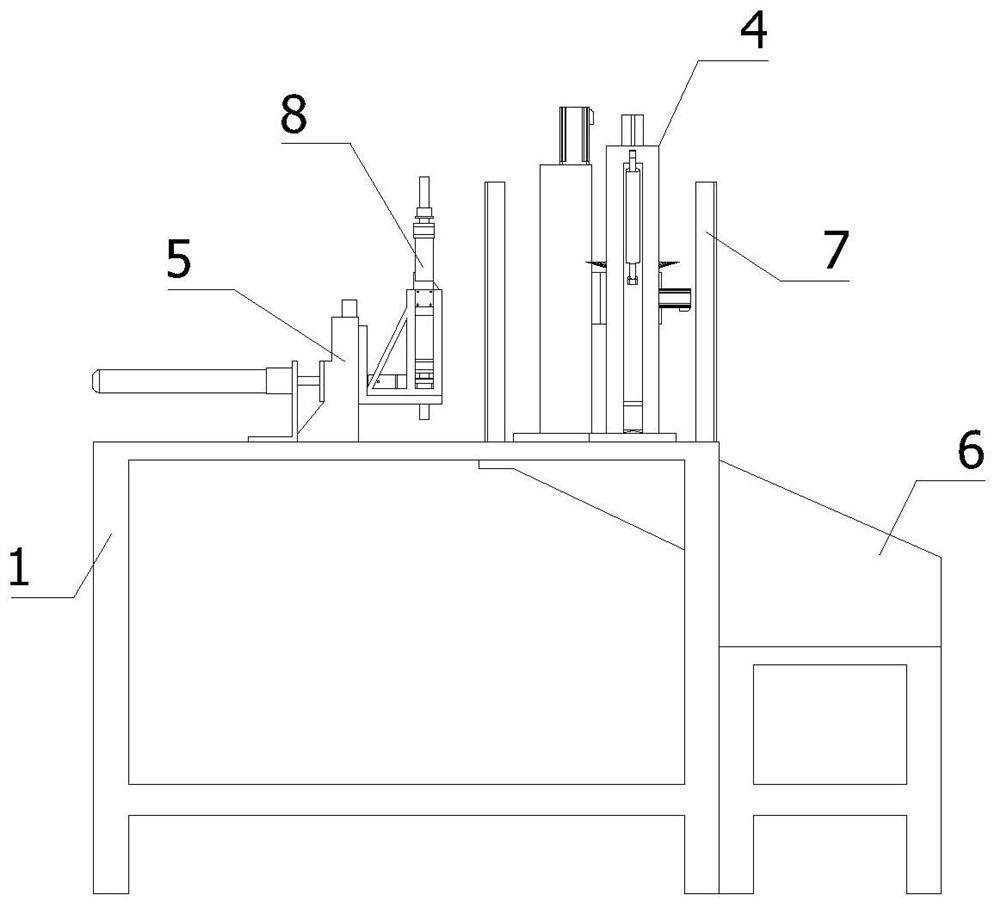

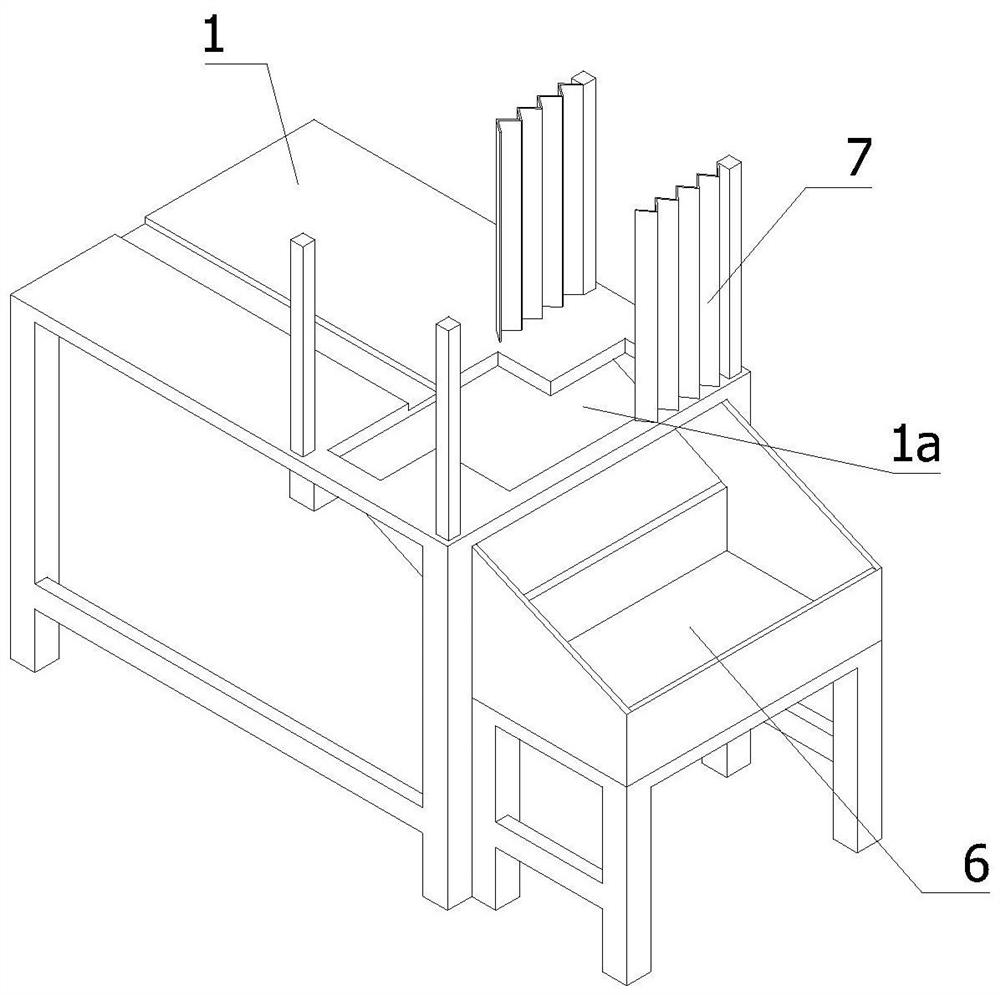

[0048] Such as Figure 1-Figure 6 Shown:

[0049] A processing equipment for the inclined plane of a forklift drive axle, comprising a workbench 1, a cutter head assembly 2 arranged on the workbench 1, and a multi-directional moving mechanism 3 arranged on the workbench 1 to drive the cutter head assembly 2 to move, and also includes The positioning assembly 4 used to position the forklift drive axle 8 in a vertical state, the positioning assembly 4 includes a fixed frame 4a arranged on the workbench 1, a movable frame 4b arranged on the fixed frame 4a, and a movable frame 4b arranged on the movable frame 4b. The positioning mechanism 4c and the movable frame 4b can move on the fixed frame 4a, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com