A fixture for robot motors

A technology of fixing devices and robots, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of outstanding heat dissipation of motors and poor heat dissipation performance of installation devices, etc., to improve heat dissipation, avoid offset, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

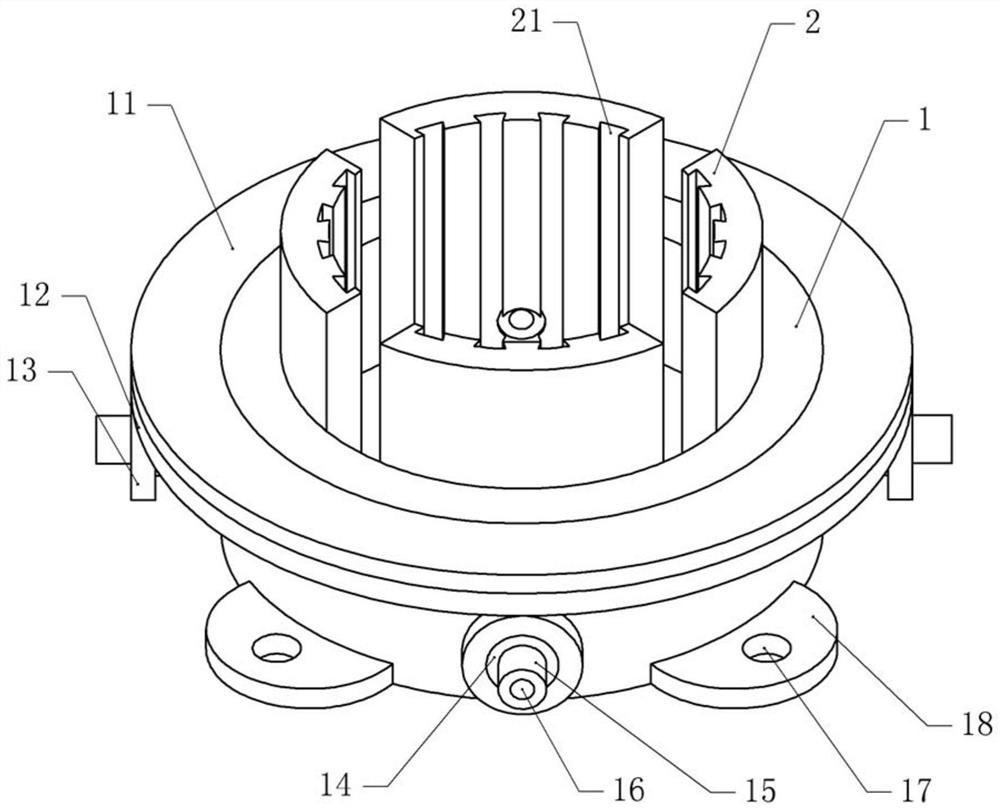

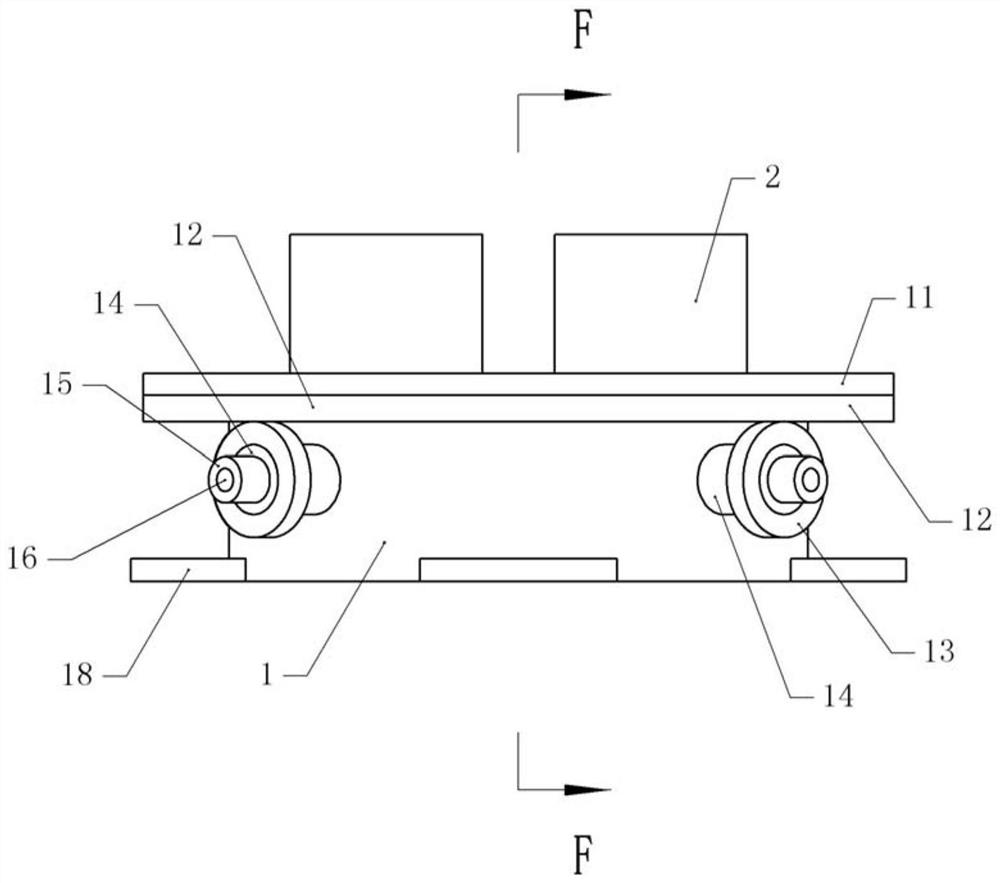

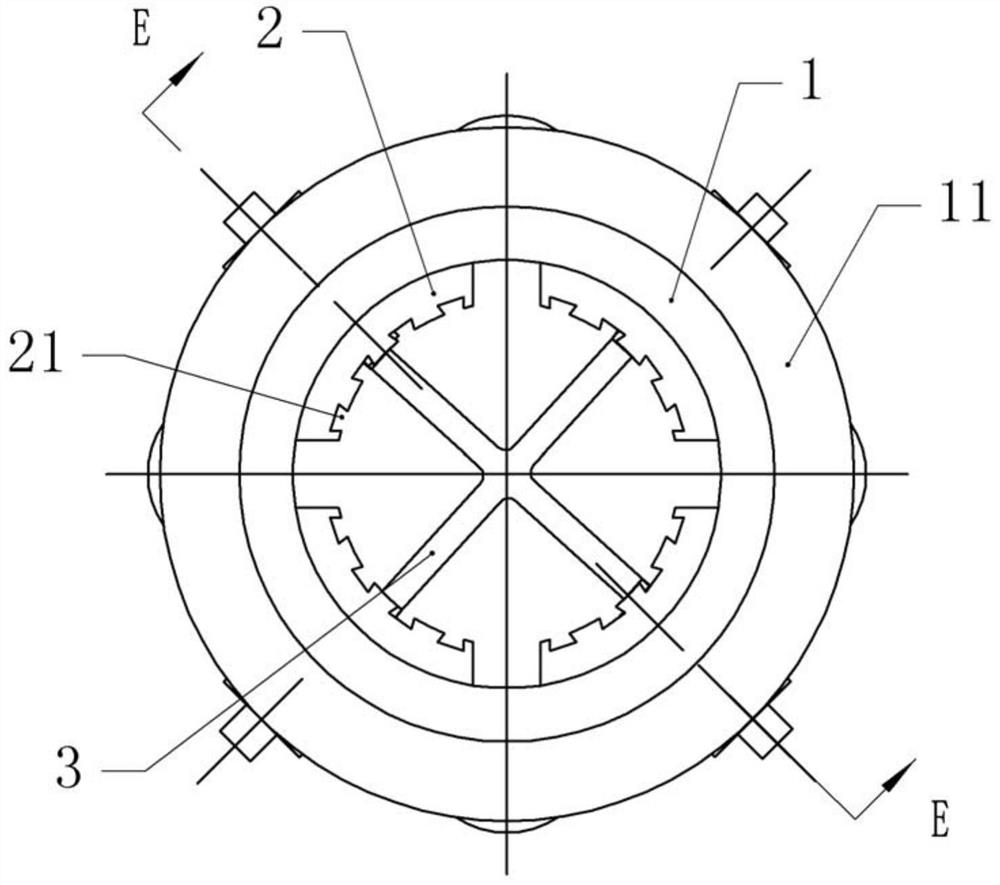

[0040] Basic as attached figure 1 , attached figure 2 And attached image 3 As shown, a fixing device for a robot motor includes a fixing seat 1, and a clamping groove with a circular longitudinal section is opened on the fixing seat 1, and a number of arc-shaped longitudinal sections are evenly distributed in the clamping groove along its circumference. As for the clamping plates 2 , there is a space between two adjacent clamping plates 2 for the heat dissipation of the motor. The bottom of the clamping groove has a chute 3, combined with the attached Figure 5 As shown, the bottom of the clamping plate 2 is welded with a slider 22 horizontally slidingly connected with the chute 3 . A plurality of cooling grooves 21 are formed on the inner side of the clamping plate 2, and the cooling grooves 21 extend to the bottom of the clamping groove.

[0041] combined with Figure 4 And attached Figure 5 As shown, the fixed base 1 is provided with several hollow outer shafts 14 ...

Embodiment 2

[0049] The difference between embodiment two and embodiment one is that, as attached Figure 6 , attached Figure 7 And attached Figure 8 As shown, the bottom of the fixed seat 1 is welded with a support seat 4 with a circular longitudinal section, an adjustment shaft (not shown in the figure) is rotatably connected to the support seat 4, and locking plates 41 are threaded on both sides of the adjustment shaft. .

[0050] When installing the fixing device for the robot motor on the desired position of the robot, first weld the adjusting shaft on the robot, then turn the support base 4, and then the support base 4 carries the fixing base 1 to adjust the orientation of the fixing base 1, Then fix the motor again. The fixed seat 1 is adjusted through the support seat 4 and the adjustment shaft to meet the requirements of different orientations (inclination angles).

[0051] The locking plate 41 is detachably connected with a positioning shaft 42, specifically: the locking pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com