Medium-temperature annealing method for superconducting cavity

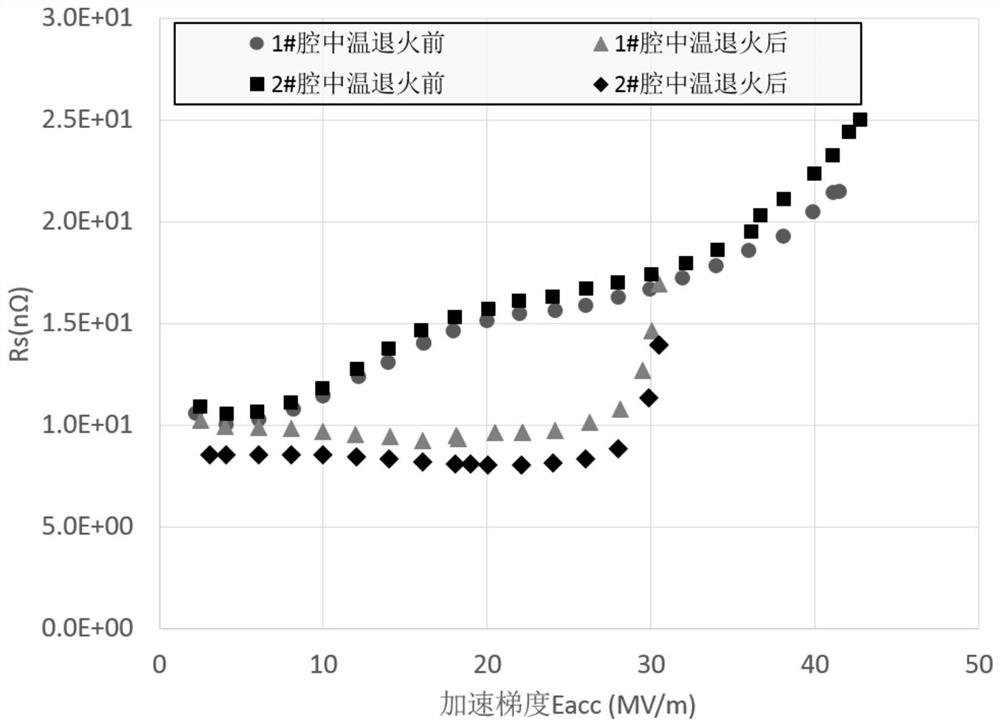

A superconducting cavity and high-temperature annealing technology, which is applied in the direction of accelerators and electrical components, can solve problems such as complex processes, achieve low process complexity, save cost and operating costs, and reduce power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

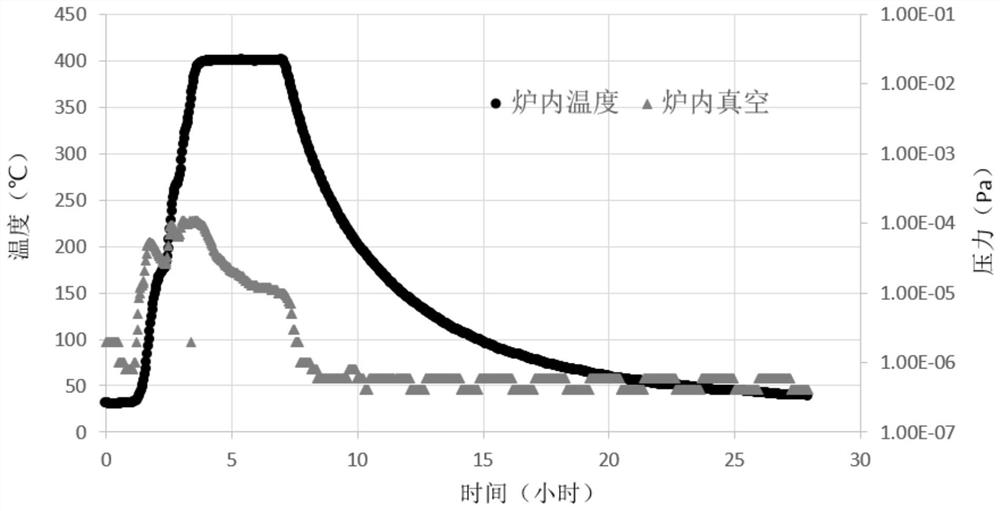

[0028] In order to better illustrate the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

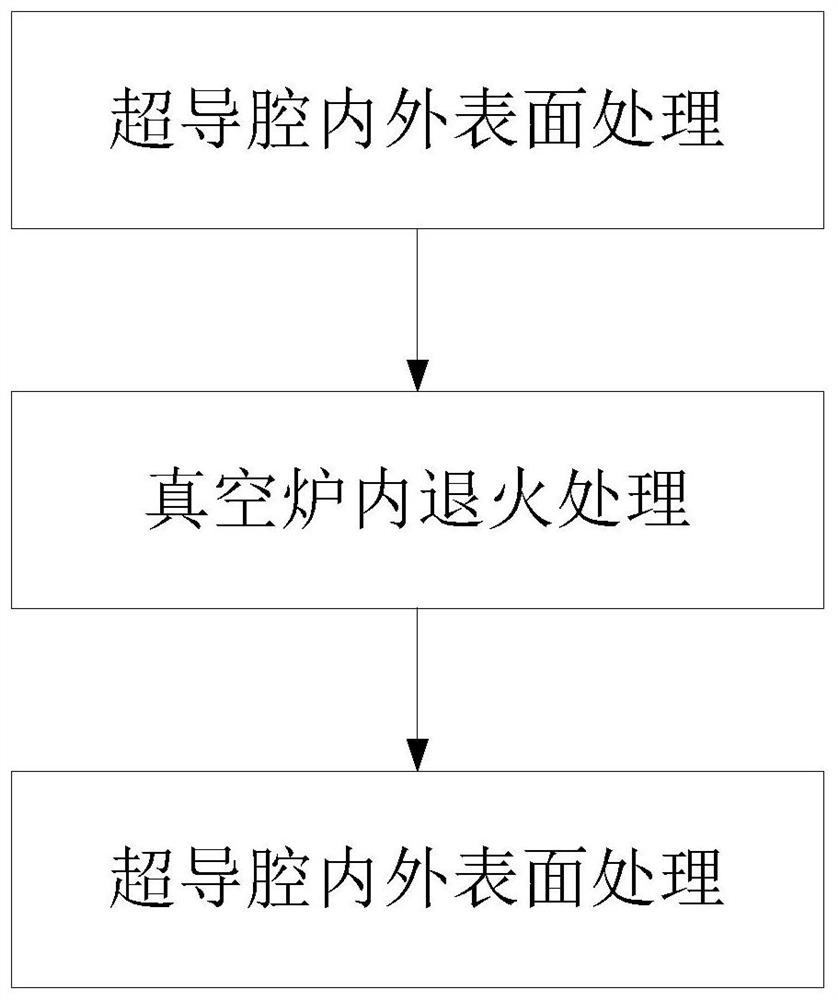

[0029] Process flow of the present invention such as figure 2 As shown, the following combination figure 2 The medium temperature annealing technology of this superconducting cavity is introduced in detail.

[0030] 1. Before the medium temperature annealing of the superconducting cavity, in order to remove the defects (potholes, bumps, pollution) on the surface (mainly the inner surface) of the superconducting cavity, the inner and outer surfaces must be pre-treated. The general process is as follows:

[0031] 1. Perform visual inspection. The inner and outer surfaces of the superconducting cavity must be smooth, flat and clean. Optically inspect the area near the weld on the inner surface to ensure that there are no obvious defects.

[0032] 2. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com