Filtering device capable of safely sub-packaging construction machinery paint and convenient to clean

A technology of construction machinery and filter devices, which is applied in the field of filter devices for safe packaging and easy cleaning of construction machinery paints, and can solve problems such as uneven mixing, low work efficiency, and slow efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

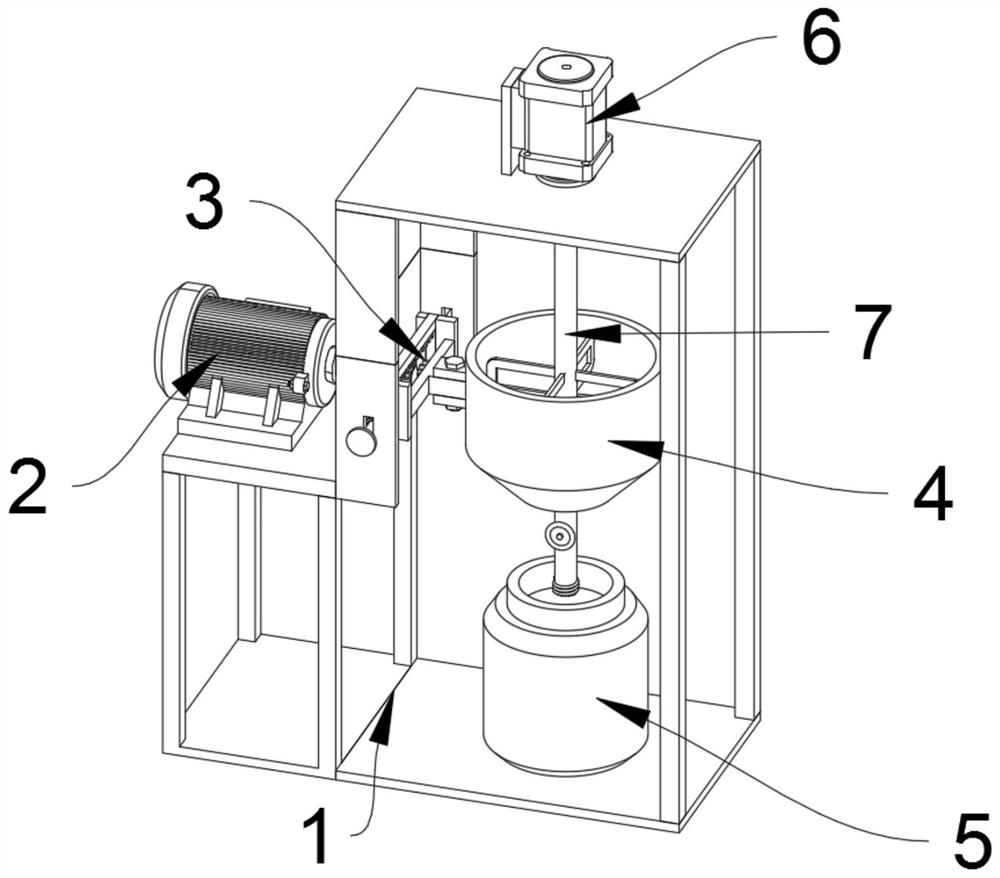

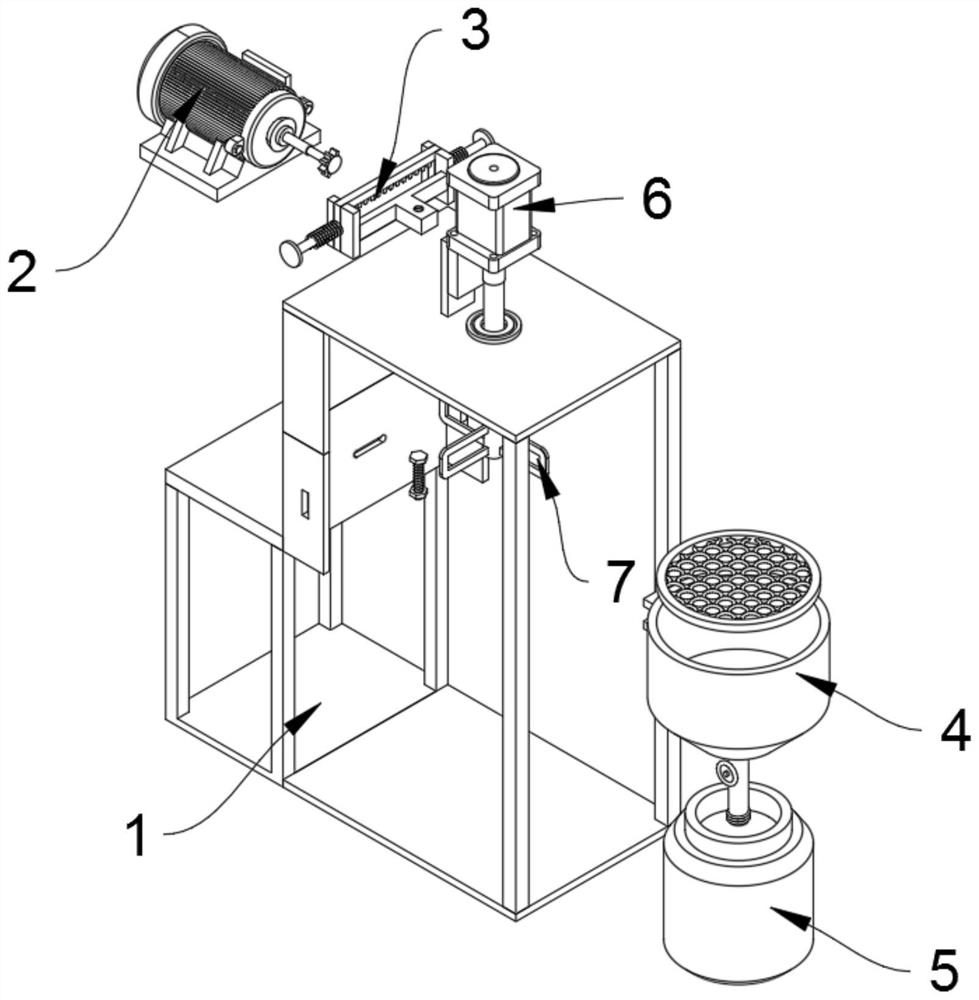

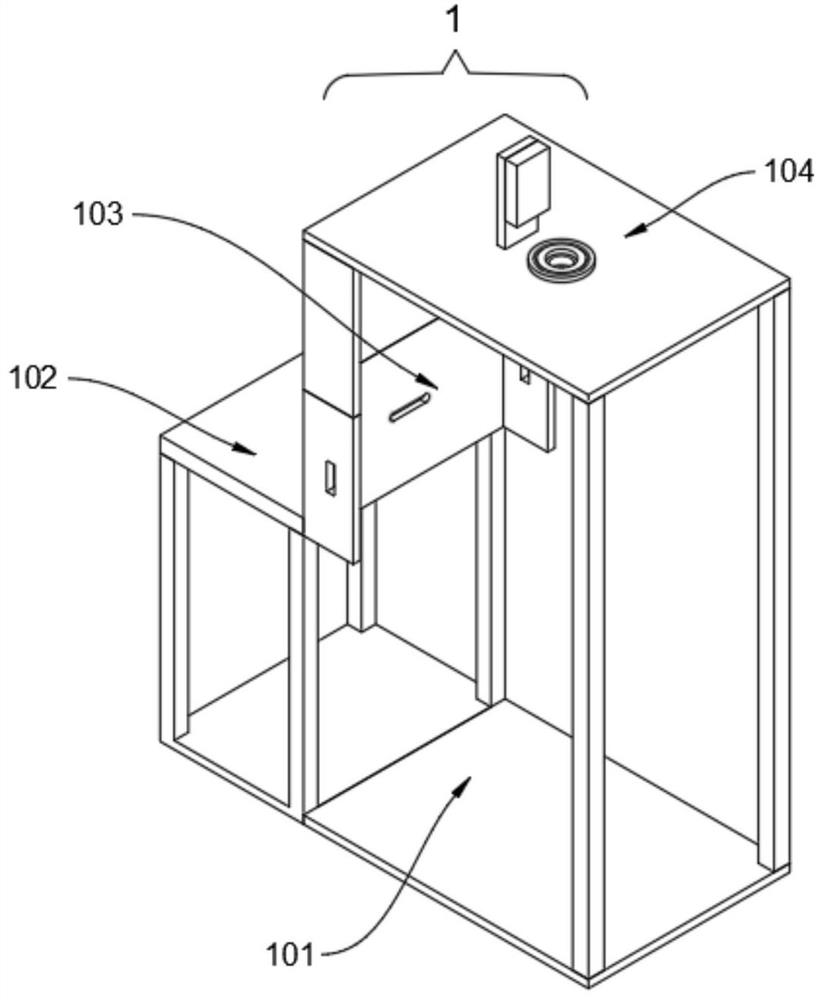

[0032] as attached figure 1 to attach Figure 9 Shown:

[0033] The present invention provides a filter device for safe packaging and easy cleaning of construction machinery paint, comprising: an oscillating power mechanism 2, an oscillating mechanism 3, a storage mechanism 5, a stirring power mechanism 6, and a stirring mechanism 7, and the bottom of the oscillating power mechanism 2 is fixedly connected At the top position of the rear end of the frame mechanism 1; the oscillation mechanism 3 is slidingly connected inside the frame body mechanism 1, and the middle position of the oscillation mechanism 3 is rotationally connected with the front end of the oscillation power mechanism 2; the front end of the oscillation mechanism 3 is in the middle position of the rear end of the feeding mechanism 4 Fixedly connected; the bottom of the storage mechanism 5 is placed at the front end of the frame body mechanism 1, and the storage mechanism 5 is located directly below the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com