Large paint spraying and drying equipment

A kind of drying equipment, large-scale technology, applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc., can solve the problem of inconvenient plate fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

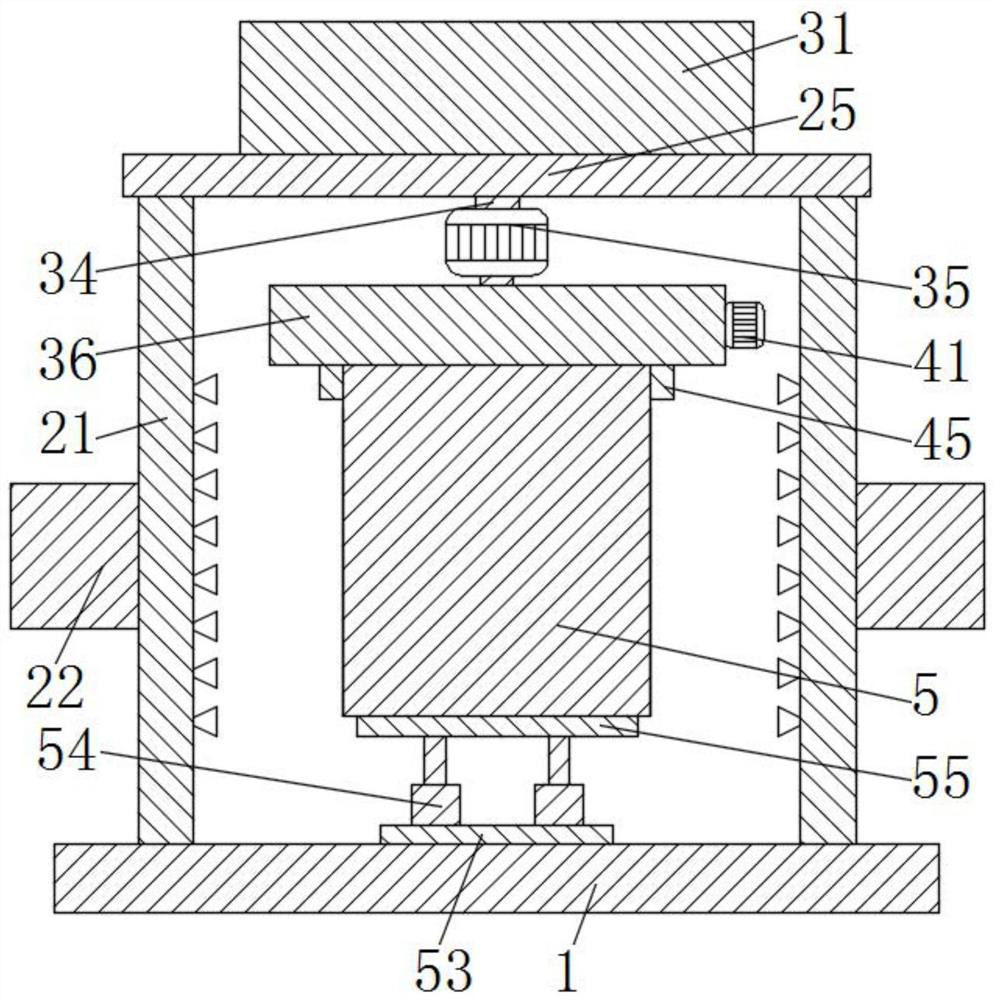

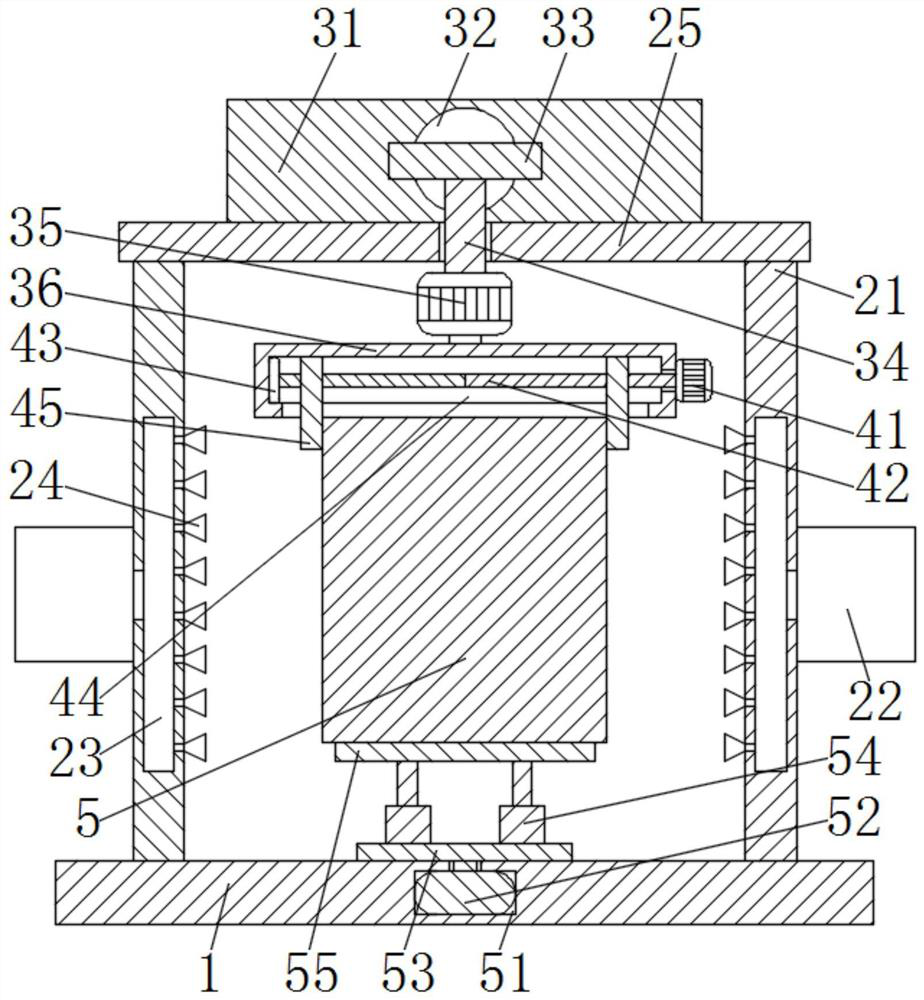

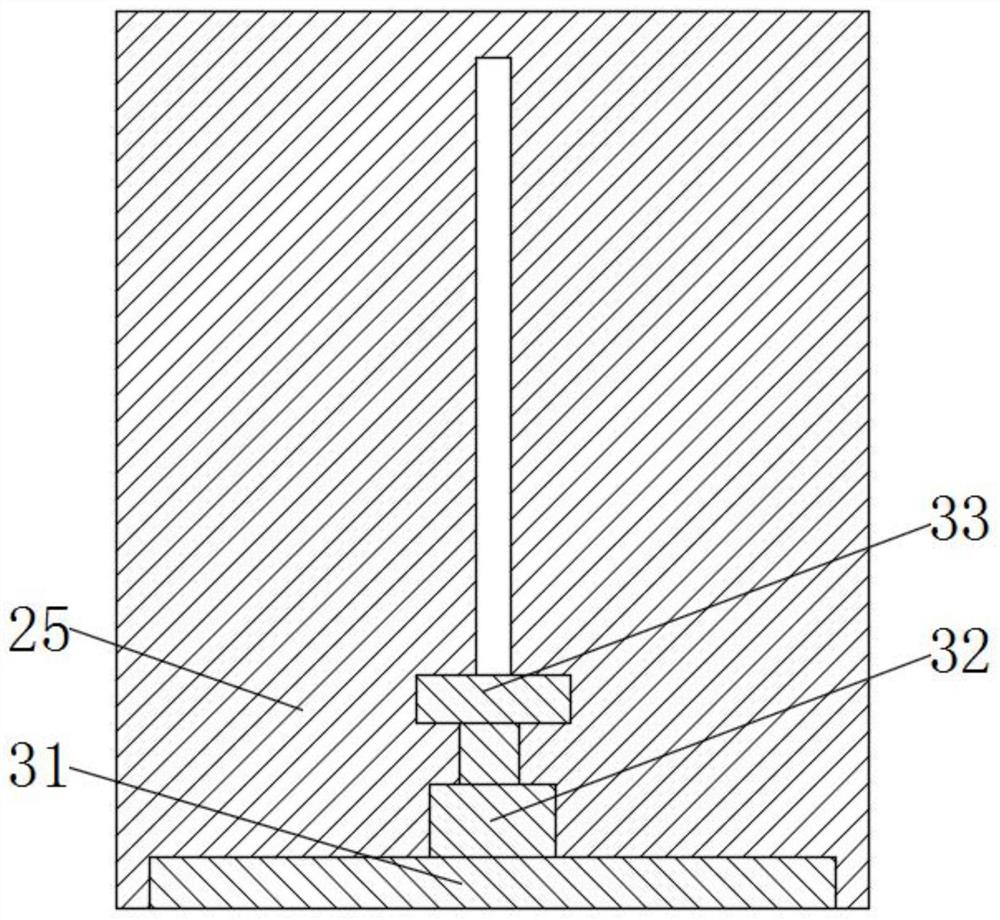

[0032] see Figure 1-Figure 5, a large-scale paint drying equipment, including a base 1, the upper end of the base 1 is provided with a side plate 21, two side plates 21 are provided, respectively welded on both sides of the upper end of the base 1, and the outer side of the side plate 21 is provided with a drying Dryer 22 and dryer 22 are fixedly installed on the outside of side plate 21. Dryer 22 is connected to ventilation groove 23 through air pipe. Dryer 22 is connected to ventilation groove 23 through air pipe. The other end of ventilation groove 23 is provided with an air outlet cover. 24. The ventilation groove 23 is set in the side plate 21, and the outside of the ventilation groove 23 is provided with an air outlet cover 24. The dryer 22 can blow hot air into the ventilation groove 23 through the air pipe, and then the hot air passes through the outlet cover on the ventilation groove 23 24 sprays out, conveniently plate 5 is carried out drying operation; The upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com