Hot-air blow-drying device for circuit board

A circuit board, hot air technology, applied in the direction of printed circuit drying, printed circuit secondary treatment, etc., can solve the problems of poor drying effect of circuit boards, etc., and achieve the effect of high use efficiency and strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

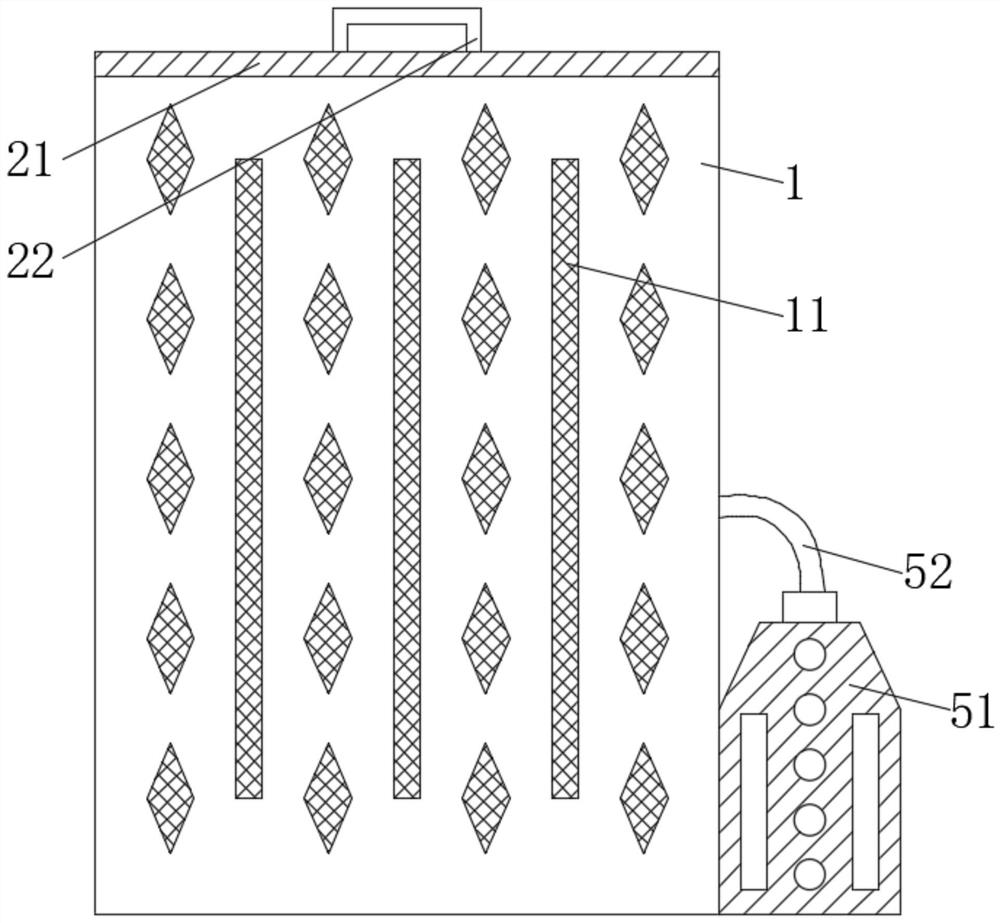

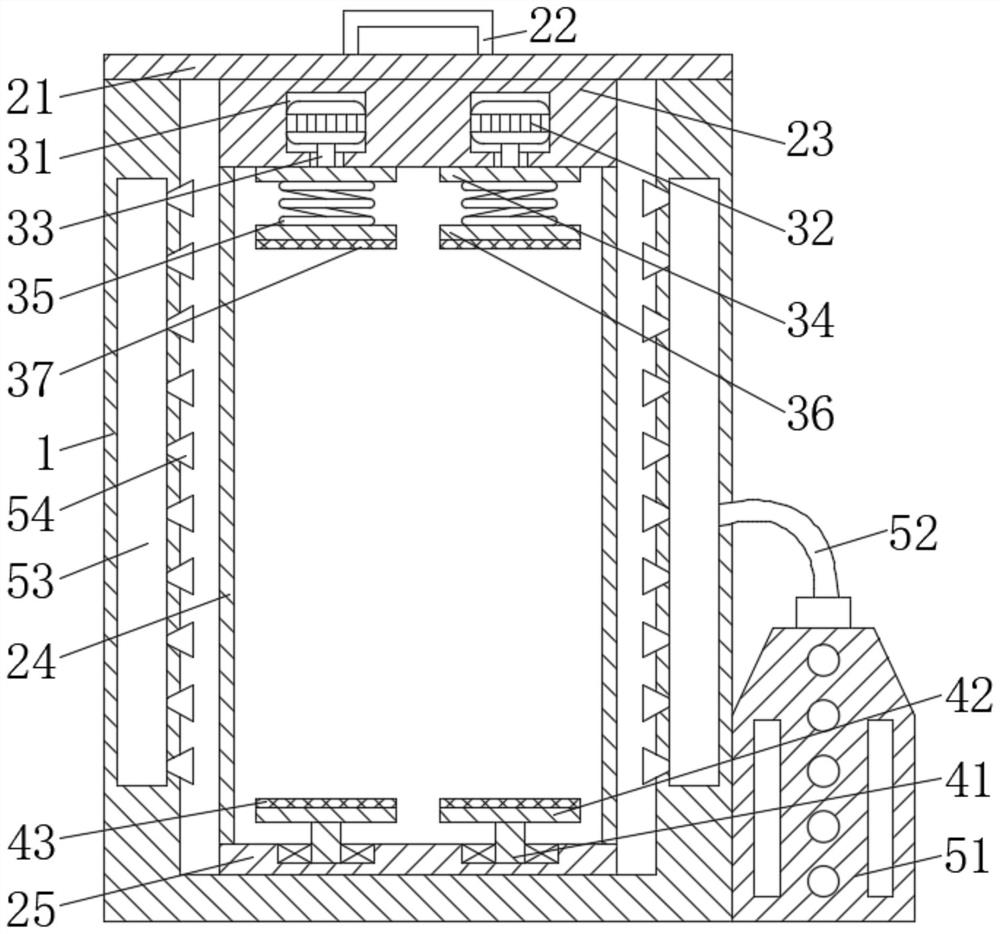

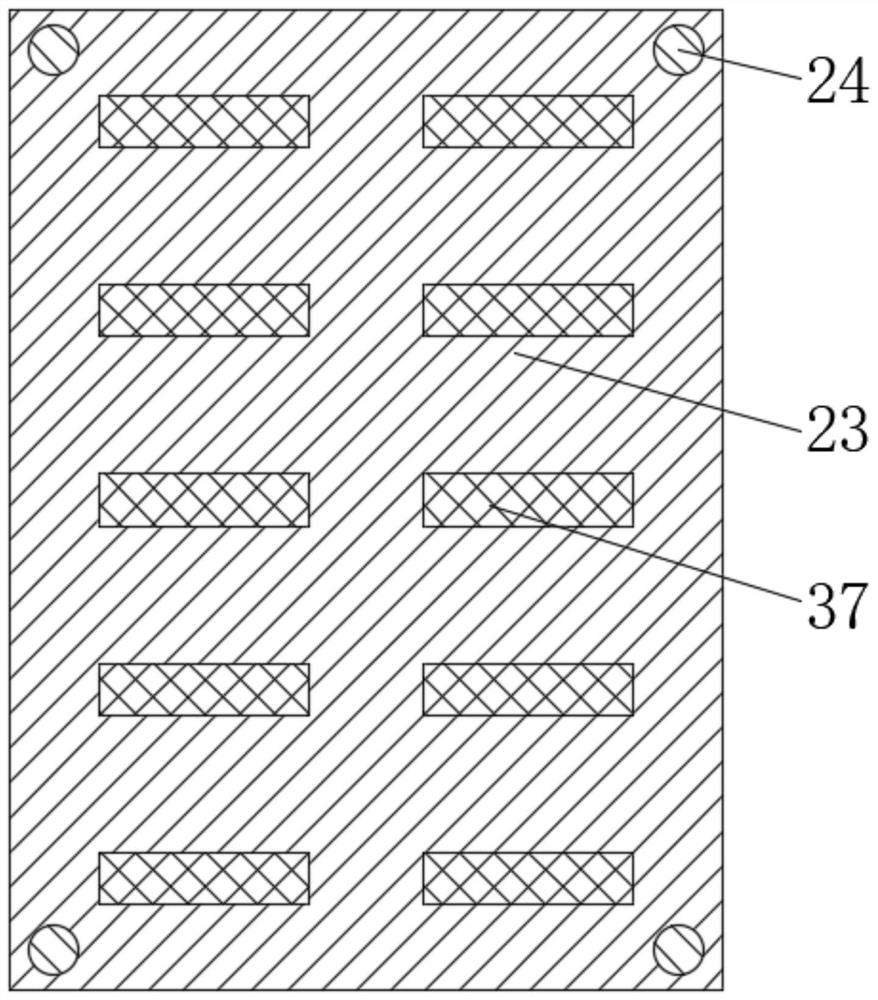

[0020] see Figure 1-Figure 3 , a circuit board hot air drying device, comprising a drying frame 1, the drying frame 1 is provided with a top plate 21, the top plate 21 rides on the drying frame 1, the upper end of the top plate 21 is provided with a handle 22, and the handle 22 is fixed Welded on the upper end of the top plate 21, and the inner side of the handle 22 is provided with a sponge block, which can protect the hands of the user. The lower end of the top plate 21 is provided with a fixed block 23, and the fixed block 23 is fixedly welded on the right lower end of the top plate 21 , the fixed block 23 stretches into the drying frame 1 and is connected with the column 24. The column 24 is provided with four, which are respectively fixedly welded at the four corners of the lower end of the fixed block 23. The lower end of the column 24 is provided with a base plate 25, and the base plate 25 is fixedly welded on the column 24 Above, there are empty slots 31 in the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com