Portable engine camshaft bushing press-fitting mechanism

A camshaft and engine technology, applied in hand-held tools, manufacturing tools, etc., can solve problems affecting the performance of the crankcase body, uneven manual pressing force, unusable special equipment, etc., to achieve convenient and fast manufacturing and low cost , The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

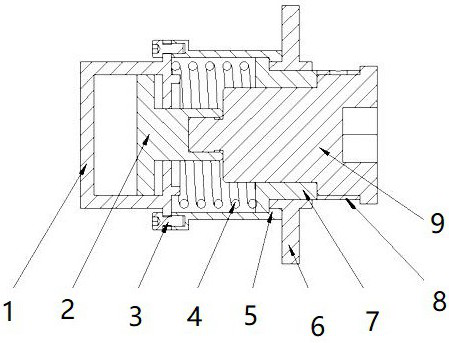

[0017] The invention discloses a portable engine camshaft bushing press-fitting mechanism, which adopts a small hydraulic device to realize the press-fitting of the camshaft bushing, has a compact structure, and is not limited by the number of crankcase cylinders, and can sequentially press-fit the multi-cylinder engine bushings ;The press-fitting force is stable and controllable, and the press-fitting is convenient. like figure 1 As shown, it includes a hydraulic cylinder block 1, and a hydraulic cylinder rod 2 is installed inside the hydraulic cylinder block 1. The output shaft of the hydraulic cylinder rod 2 is a circular structure, passing through both sides of the end of the hydraulic cylinder block 1 towards the hydraulic cylinder rod 2. The connecting bolt 3 is connected with the outer guide sleeve 5. The outer guide sleeve 5 is in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com