Glass fibre winding water container

A technology of glass fiber and water containers, applied in the field of pressure vessels, to achieve the effect of ensuring tightness, solving hidden dangers, and improving peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

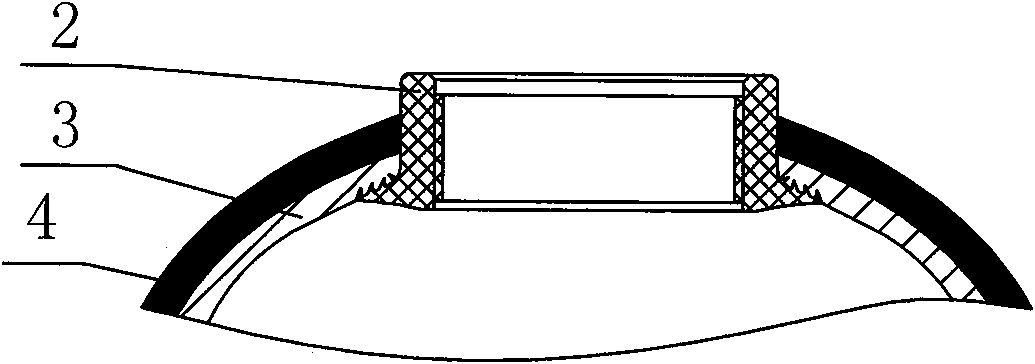

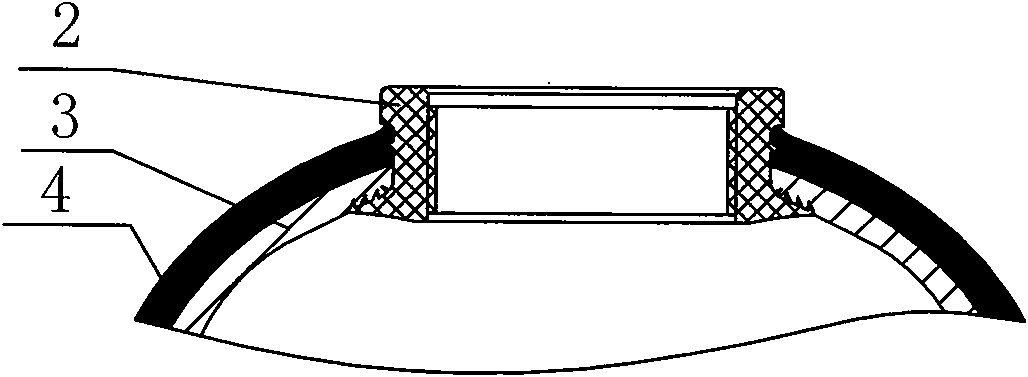

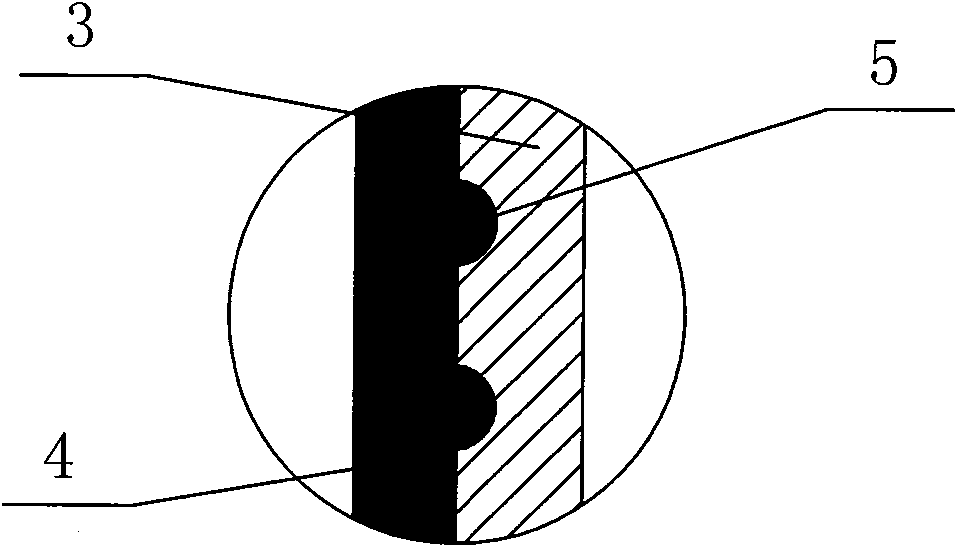

[0023] Such as figure 1 As shown, the present invention includes a base 1 for fixing the bottom, an inner tank 3, a threaded joint 2 fixedly connected at the neck of the inner tank 3 top, and a glass fiber winding layer wrapped outside the inner tank 3 and protecting the inner tank 3 4. The connection method between the liner 3 and the glass fiber winding layer 4 is bonding. In practical applications, the threaded interface 2 can also be arranged at the neck of the inner tank 3 bottom. Such as image 3 , Figure 5 As shown, the outer wall of the threaded interface 2 is correspondingly provided with an annular mosaic structure 7 for inlaying and fixing the end of the glass fiber winding layer 4 and a limiting protrusion preventing the threaded interface 2 from retracting into the glass fiber winding layer 4 . Wherein, the position-limiting protrusion is an annular protrusion 6 arranged on the upper part of the threaded interface 2, and the annular protrusion 6 is integrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com