Cutting, discharging and arranging device for integrated circuit element packaging pipes

An integrated circuit and finishing device technology, which is applied in the field of integrated circuit component packaging tube cutting and unloading finishing devices, can solve problems such as low work efficiency, affecting use, and messy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

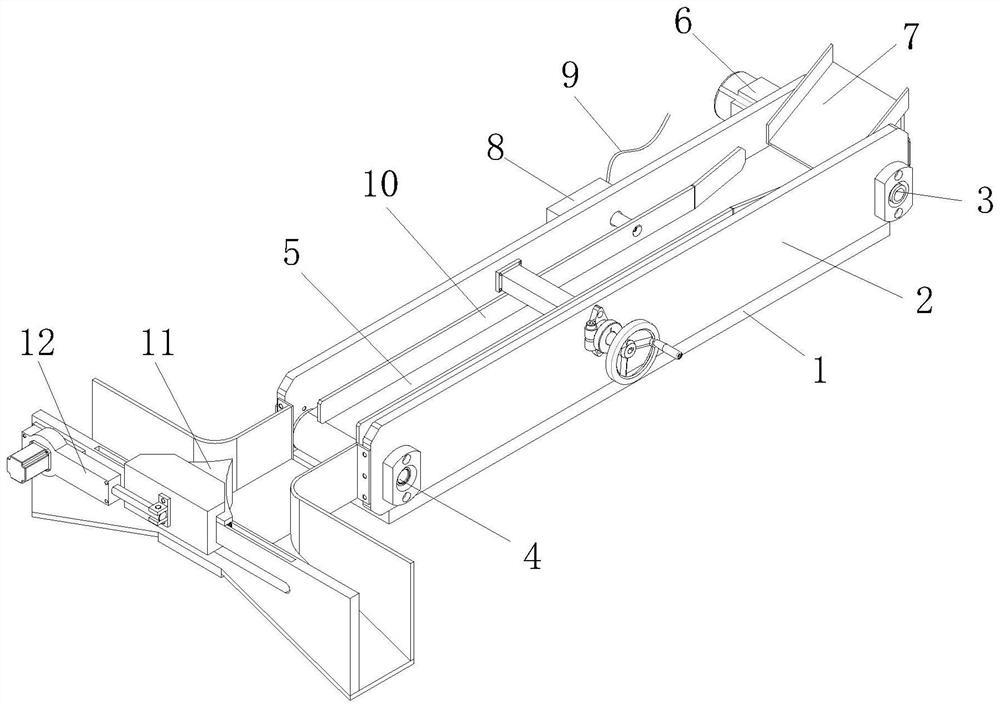

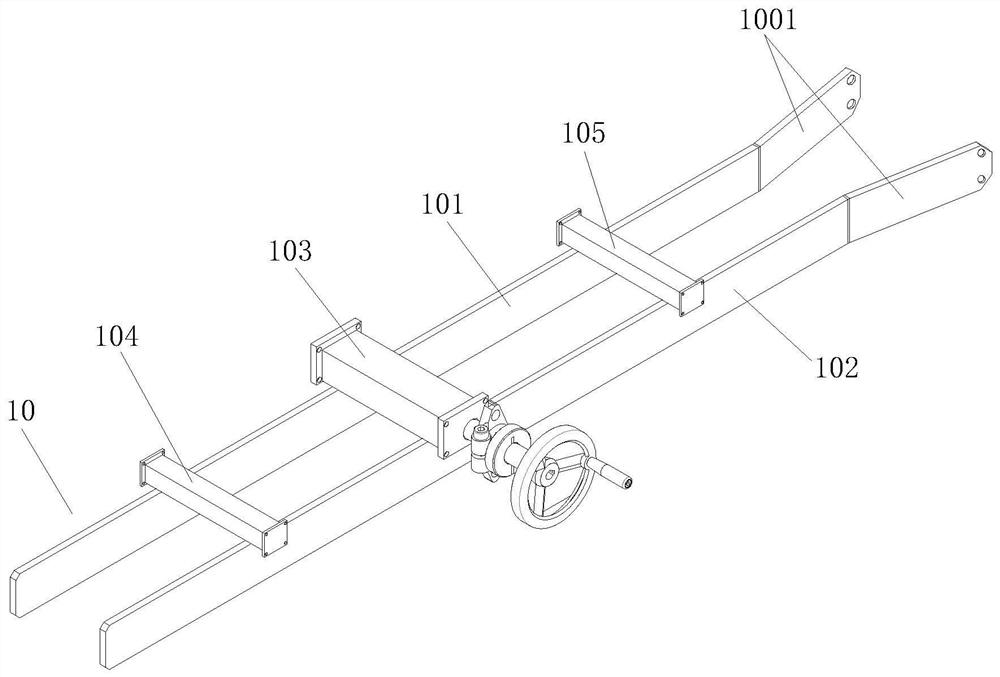

[0031] see figure 1As shown, the present invention provides a kind of integrated circuit component packaging tube cutting and blanking finishing device through improvement, including frame 1, side plate 2, driving roller 3, driven roller 4, conveyor belt 5, first motor 6, lower Hopper 7, control panel 8, external power cord 9, transmission guide device 10, intermittent sorting device 11 and circulation push mechanism 12, side panels 2 are installed on the upper side of frame 1 to prevent materials from falling out, and the front and rear ends are respectively installed There are driven rollers 4 and driving rollers 3, which are used to drive the conveyor belt 5 to rotate for conveying work. The inner side of the side plate 2 is provided with a conveyor belt 5, which can convey the packaging tube materials, and the conveyor belt 5 is connected with the driven roller 4 and the driving roller 3. Transmission connection, a first motor 6 is installed on the left side of the rear en...

Embodiment 2

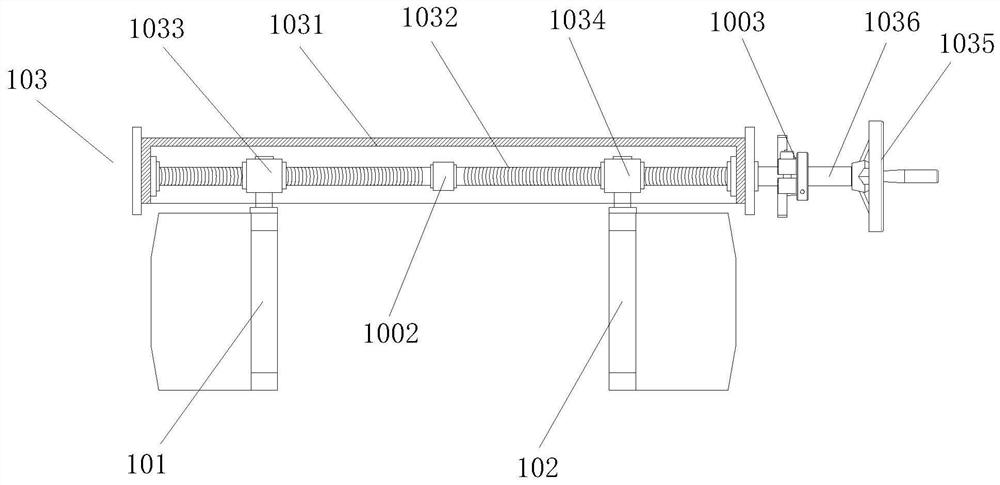

[0038] The present invention provides a device for cutting and unloading integrated circuit component packaging tubes through improvement. The shape of the stopper block 1110 matches the arc surfaces at the corners of the left L-shaped plate 111 and the right L-shaped plate 112, so that the stopper block 1110 is displaced. When reaching the corner of the L-shaped plate 111 or the right L-shaped plate 112, it can be blocked with the lane opening 115 formed by the fixed main board 114, so that the lane opening 115 at the other end is opened, thereby realizing intermittent sorting and discharging arrangement, intermittent sorting device The feed end of 11 is docked with the discharge end of the front end of the conveyor belt 5, so that the material conveyed on the conveyor belt 5 directly enters the intermittent sorting device 11 for feeding and sorting, and one end of the screw rod 1032 is rotationally connected with one end of the inner wall of the fixed outer shell 1031 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com