Flue construction method

A construction method and flue technology, applied to vertical pipes, building components, buildings, etc., can solve problems such as easy water seepage, hidden danger of leakage at the joint between the flue and concrete structure, and difficulty in installing the flue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

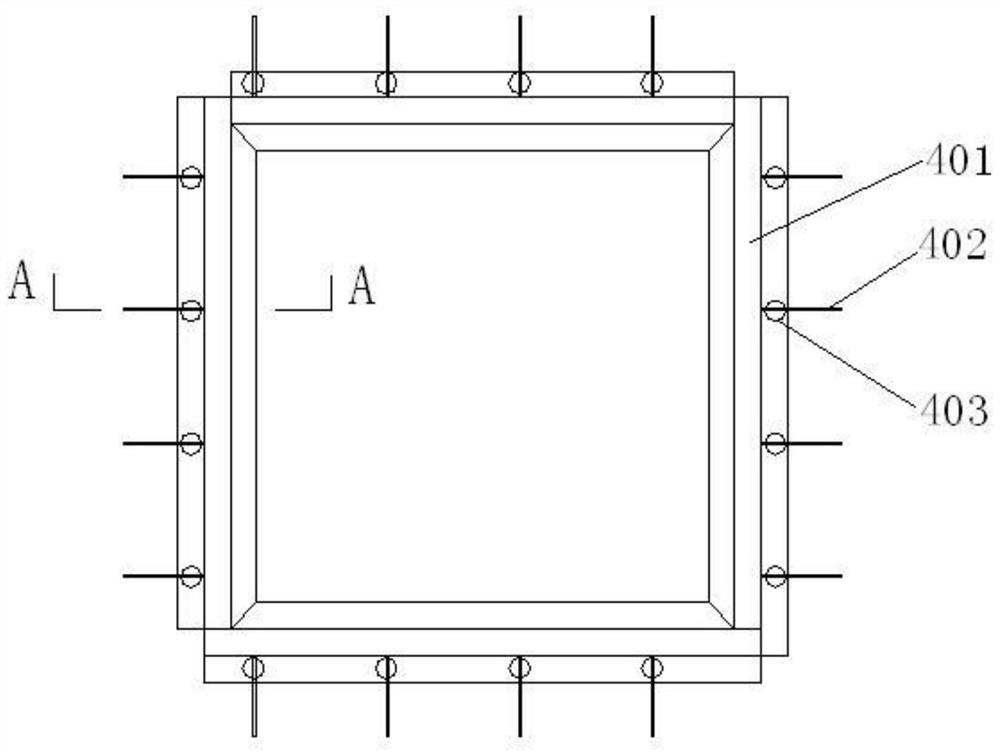

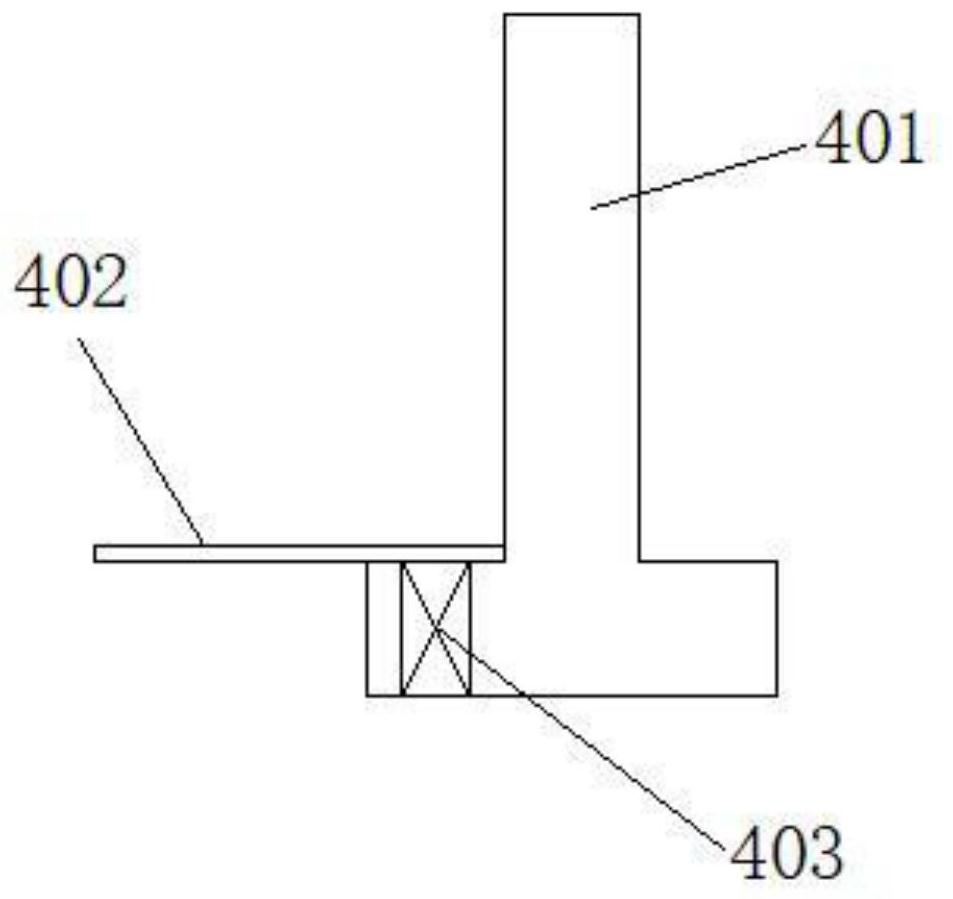

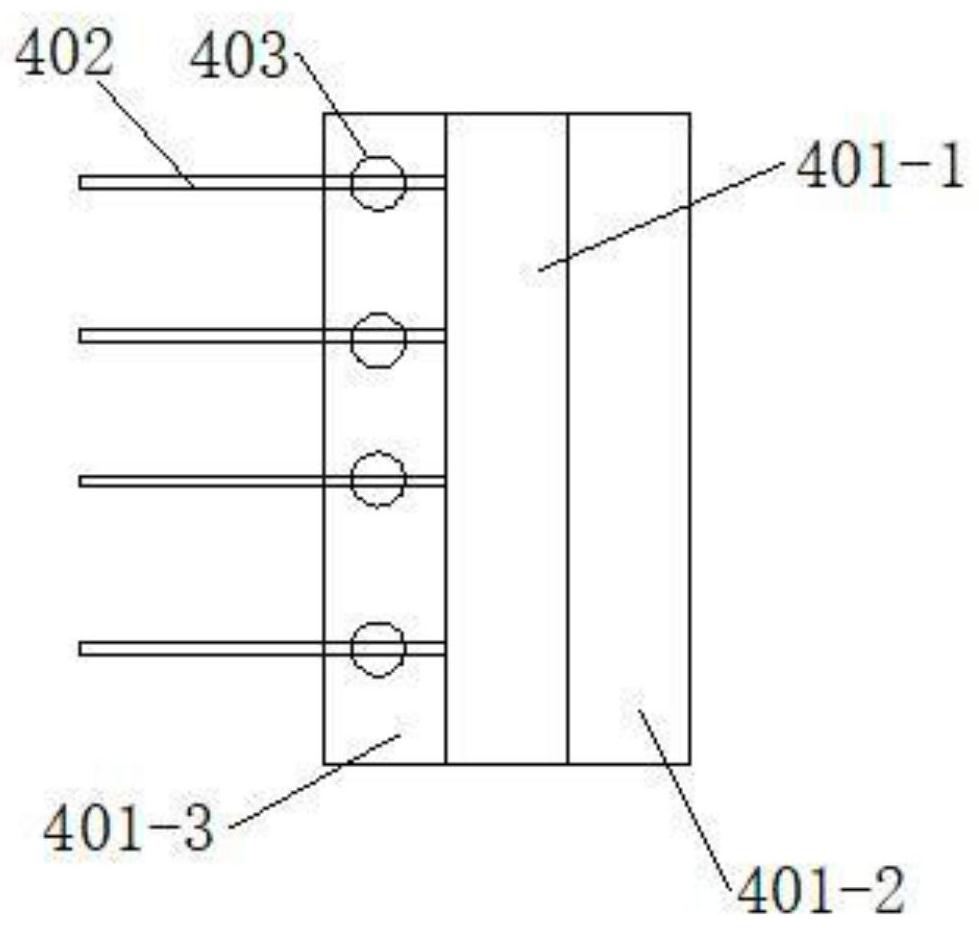

[0022] As shown in the accompanying drawings, a flue construction method uses a flue installation device 4 for construction. The flue installation device 4 includes a rectangular frame steel supporting member, and the four frames of the steel supporting member are composed of a T-shaped steel skeleton 401 in section. The cross-section of the steel frame 401 is T-shaped, including a web 401-1, an inner flange 401-2, and an outer flange 401-3. The steel frame 401 can be manufactured by plate welding. The webs 401-1 of the steel frame 401 of the four frames of the steel supporting member are connected to each other to form a rectangular web frame matching the cross-sectional size of the flue, and the four corners of the rectangular web frame are sealed and connected. Several through holes 403 are provided on the outer wing plate 401-3 of each steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com