A pipe blocker

A technology for occluders and pipelines, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., and can solve problems such as difficulty and heavy workload, lax sealing, and high matching degree of equal-diameter holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] First of all, it needs to be explained that the orientation words such as up, down, left, right, front, and back described in the present invention are only described according to the accompanying drawings, so as to be easy to understand, and are not intended to limit the technical solution and scope of protection of the present invention. .

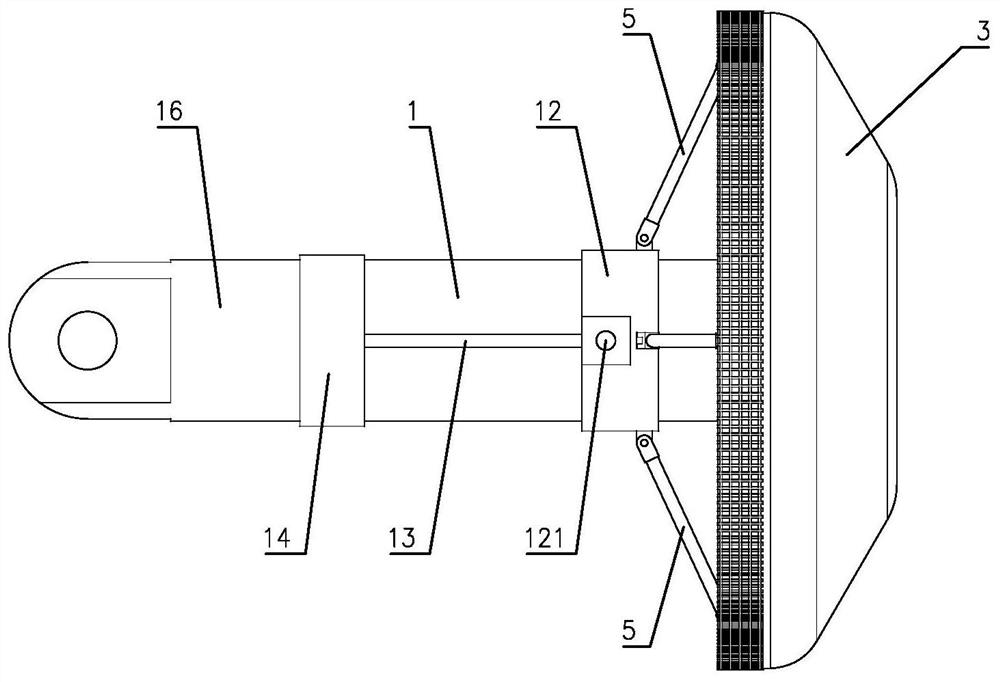

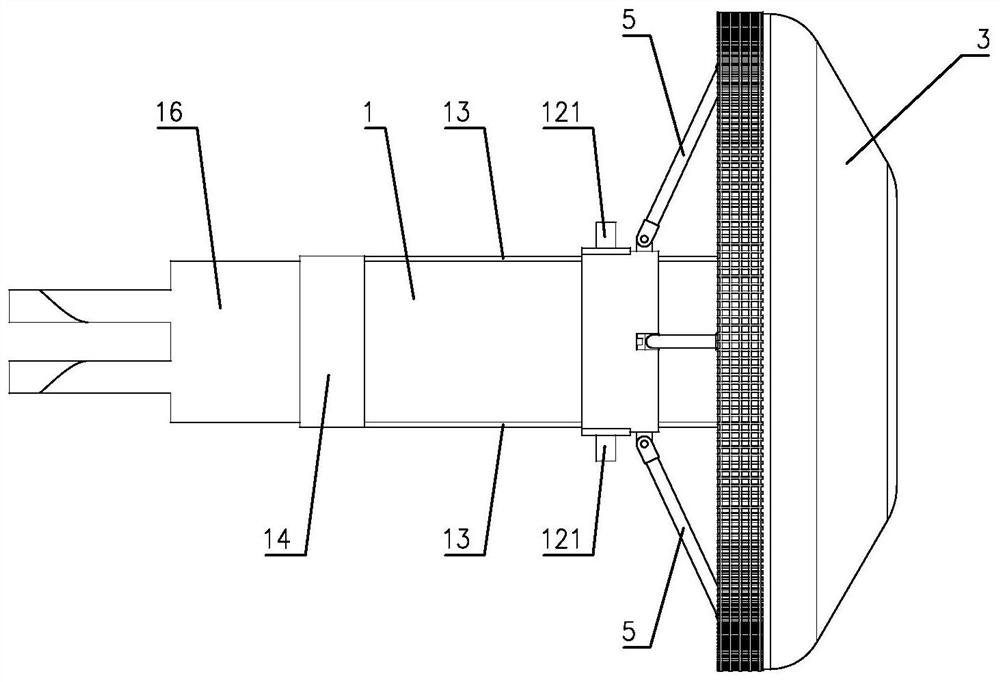

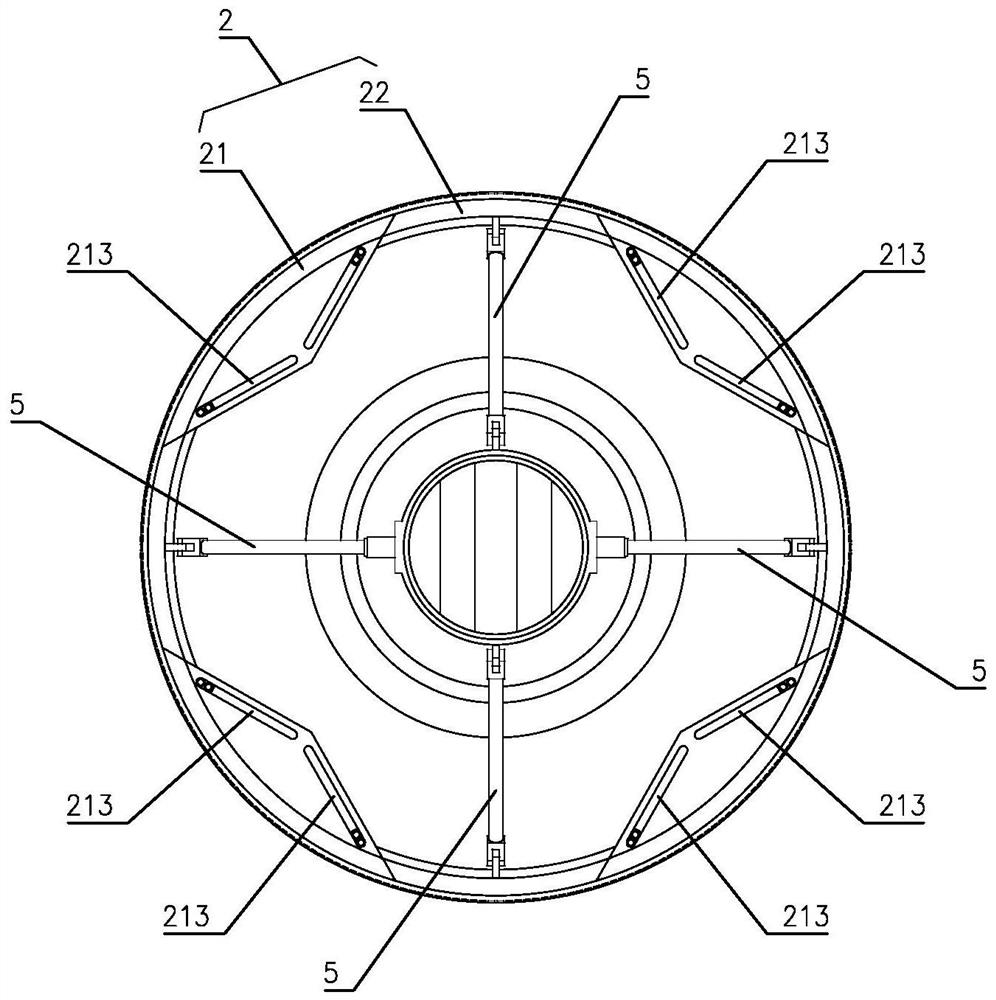

[0038] Such as Figure 1 to Figure 21 Shown is a specific embodiment of a pipeline occluder of the present invention, including a support rod 1 , an expansion ring 2 and a sealing cover 3 . A fixed ring 11 is provided at the right end of the support rod 1 , and a slip ring 12 is sleeved at the middle of the support rod 1 . The expansion ring 2 is arranged coaxially with the support rod 1 , and the expansion ring 2 is provided with first arc-shaped pieces 21 and second arc-shaped pieces 22 alternately distributed along the circumferential direction. A guide portion 211 is set on the inner side of the first arc-shaped member 21, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com