Double-fan-blade humidifying heater

A dual-blade and heater technology, applied in air humidification systems, heating methods, central heating components, etc., can solve problems such as air drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

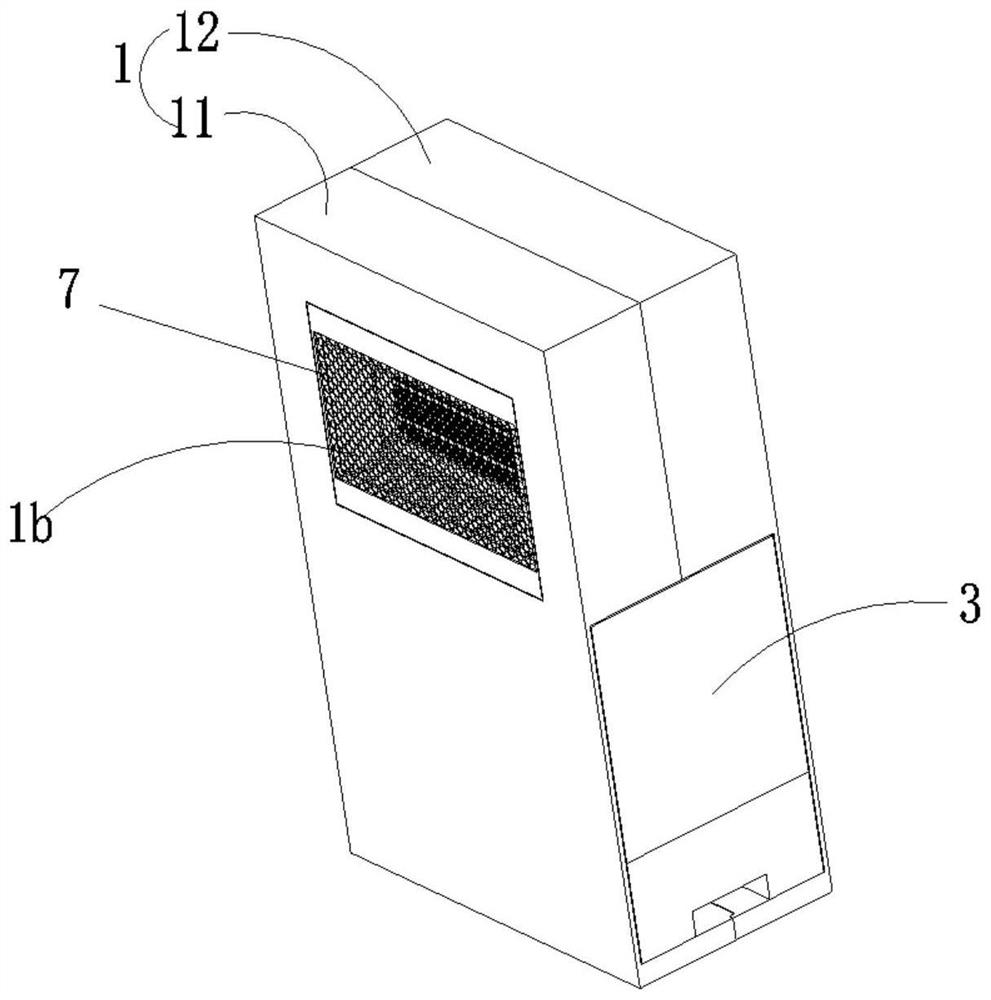

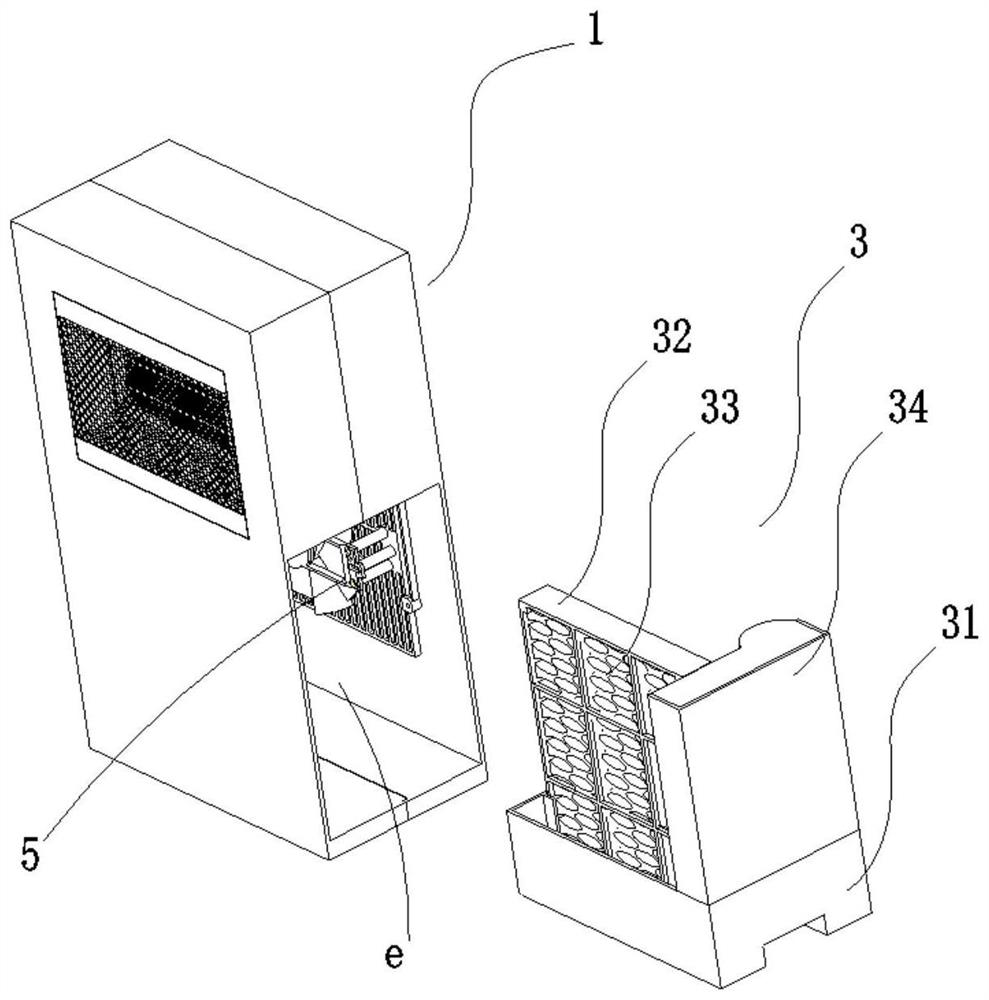

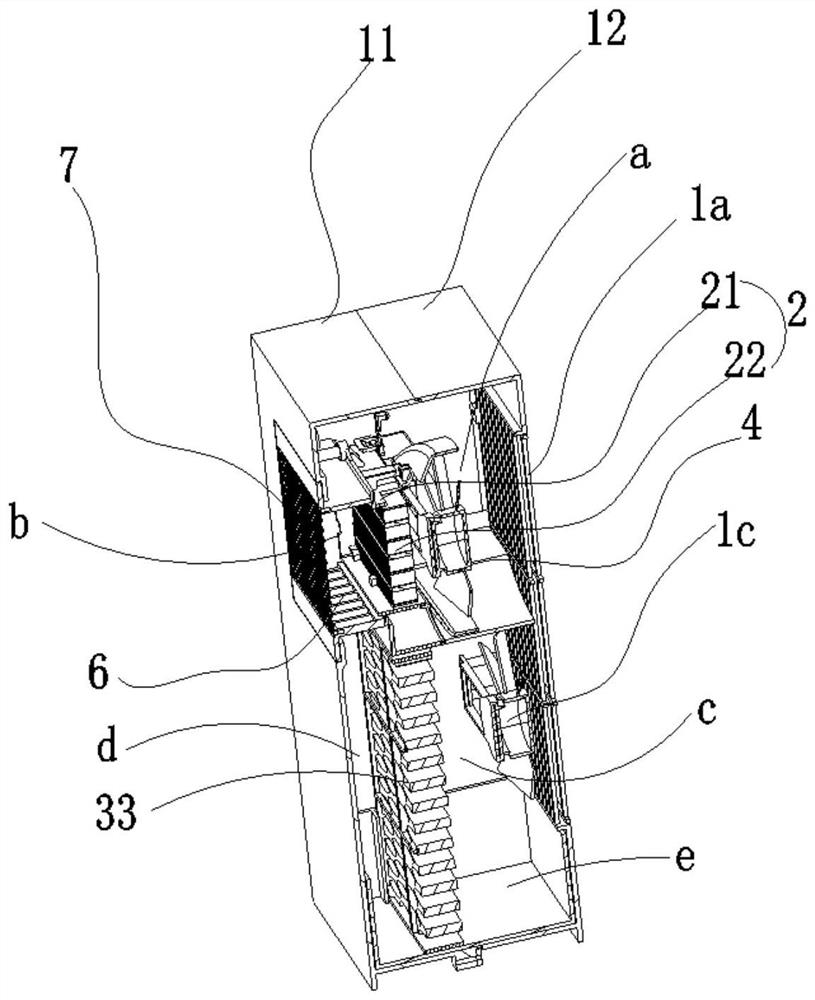

[0042] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention provides a double-blade humidification heater, including a casing 1, a heating assembly 2 and a humidifying assembly 3 located in the casing 1, and the heating assembly 2 and the humidifying assembly 3 are independently arranged in the casing 1 The warm air inlet channel a and the warm air outlet channel b are formed between the heating component 2 and the housing 1, and the warm air inlet channel b corresponding to the warm air inlet channel a and the warm air outlet channel b is provided on the housing 1 The air outlet 1a and the warm air outlet 1b, the heating fan 4 is arranged in the warm air inlet channel a; the humidification air inlet channel c and the humidification air outlet channel d are formed between the humidification component 3 and the casing 1, and the casing 1 is provided with The humidification air inlet 1c corresponding to the humidification air inlet channel c i...

Embodiment 2

[0051] Such as Figure 5 and Figure 6 As shown, different from Embodiment 1, the present invention also has a humidification air outlet 1d connected to the humidification air outlet channel d on the casing 1, and the humidification air outlet 1d is located below the warm air outlet 1b, wherein The humidification air outlet channel d is directly connected to the humidification air outlet 1d, that is, the heating and humidification channels are separated.

[0052] Such as Figure 5 As shown, the fan grille is installed at the humidification air outlet 1d, and the blowing direction can be adjusted by adjusting the angle of the fan grille. The humidifying fan 5 sucks in the external air from the humidifying air inlet 1c and enters the humidifying air inlet channel c, is humidified by the humidifying component 3 and then discharged from the humidifying air outlet 1d after passing through the humidifying air outlet channel d.

[0053] When heating is used, driven by the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com