An insulating frame for installing electrical equipment

A technology for electrical equipment and insulating racks, applied in the field of electrical equipment, can solve problems such as injury to installers, wear of insulating bases of insulating racks, and reduction of service life of insulating racks, so as to increase the contact area, reduce service life, and prevent installation personnel. effect of electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

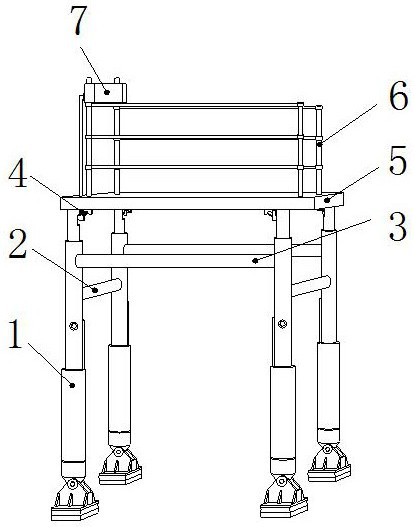

[0024] as attached figure 1 to attach Figure 5 Shown:

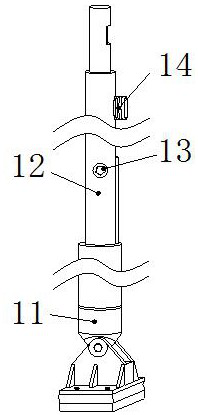

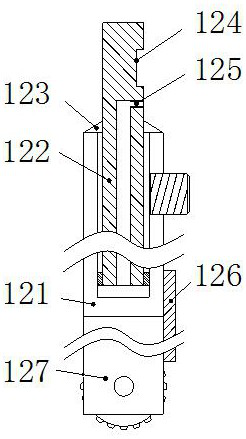

[0025] The invention provides an insulating frame for installing electric equipment, the structure of which includes an adjusting bracket 1, a first connecting rod 2, a second connecting rod 3, a buckle 4, a platform 5, a guardrail 6, and a controller 7. The middle part of the adjusting bracket 1 It is screwed to the outer end of the first connecting rod 2, the second connecting rod 3 is screwed to the middle of the adjustment bracket 1, one end of the buckle 4 is engaged with the upper end of the adjustment bracket 1, and the other end is welded to the lower side of the platform 5 connection, the lower end of the platform 5 is engaged with the upper end of the adjustment bracket 1, the lower end of the guardrail 6 is bolted to the upper end of the platform 5, the controller 7 is interference fit with the upper end of the guardrail 6, and the adjustment bracket 1 includes a balance bottom bar 11. Lifting mandrel 12, ro...

Embodiment 2

[0032] as attached Image 6 to the attached Figure 7 shown:

[0033] The contact base 11g includes a rotating shaft g1, a connecting plate g2, an insulating block g3, a reinforcing rib g4, a supporting plate g5, a dustproof cloth g6, a positioning column g7, a spring g8, and a grounding plate g9. The rotating shaft g1 and the positioning head 11f The lower end of the shaft is connected, the middle part of the upper end of the connecting plate g2 is connected to the outside of the rotating shaft g1 by welding, the insulating block g3 is connected between the connecting plate g2 and the support plate g5, and the reinforcing rib g4 is welded to the outside of the support plate g5. The dustproof cloth g6 is connected between the supporting plate g5 and the grounding plate g9, the upper end of the positioning column g7 is movably engaged with the supporting plate g5, and the lower end is connected with the inner thread of the grounding plate g9, and the spring g8 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com