Resistance measuring apparatus, film manufacturing apparatus, and manufacturing method of conductive film

A conductive film and resistance measurement technology, which is used in measurement devices, parts of electrical measurement instruments, and measurement of electrical variables, etc., can solve problems such as poor surface resistance quality, and achieve the effect of improving measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

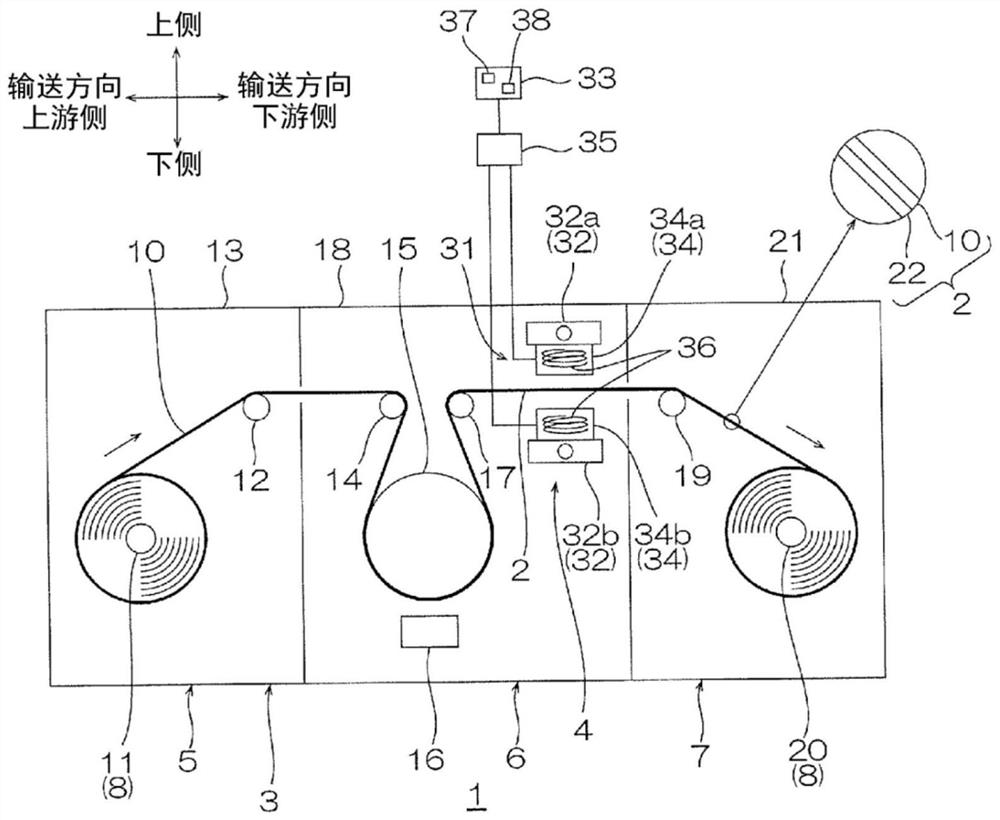

[0034] exist figure 1 In the drawing, the left-right direction of the drawing is the conveying direction (the first direction, the longitudinal direction, the first direction), the right side of the drawing is the downstream side of the conveying direction (the first direction side, the lengthwise side), and the left side of the drawing is the conveying direction The upstream side (the other side in the first direction, the other side in the longitudinal direction). The thickness direction of the paper is the width direction (the second direction perpendicular to the first direction), the front side of the paper is the width direction side (the second direction side), and the deep side of the paper surface is the other side in the width direction (the second direction). The other side). The upper and lower directions of the paper are the up-down direction (the third direction orthogonal to the first and second directions, the thickness direction), the upper side of the paper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com