Filtering system of dish-washing machine and dish-washing machine with filtering system

A filtration system and dishwasher technology, applied in the washing machine/rinsing machine of tableware, parts of washing machine/rinsing and rinsing machine of tableware, household appliances, etc., can solve the problems of doping, clogging of drainage pump, accumulation of particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

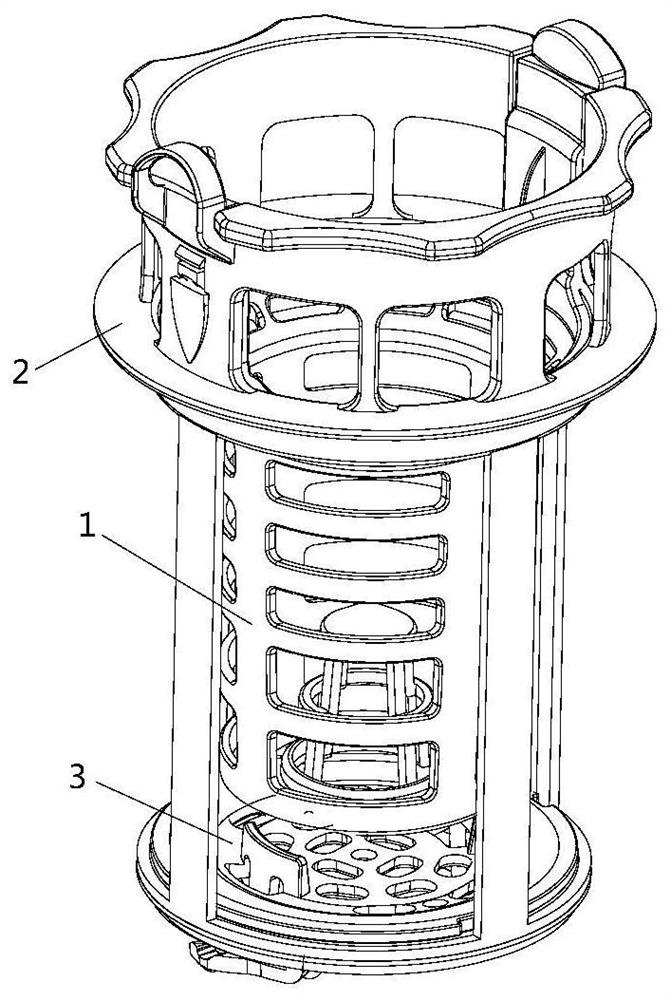

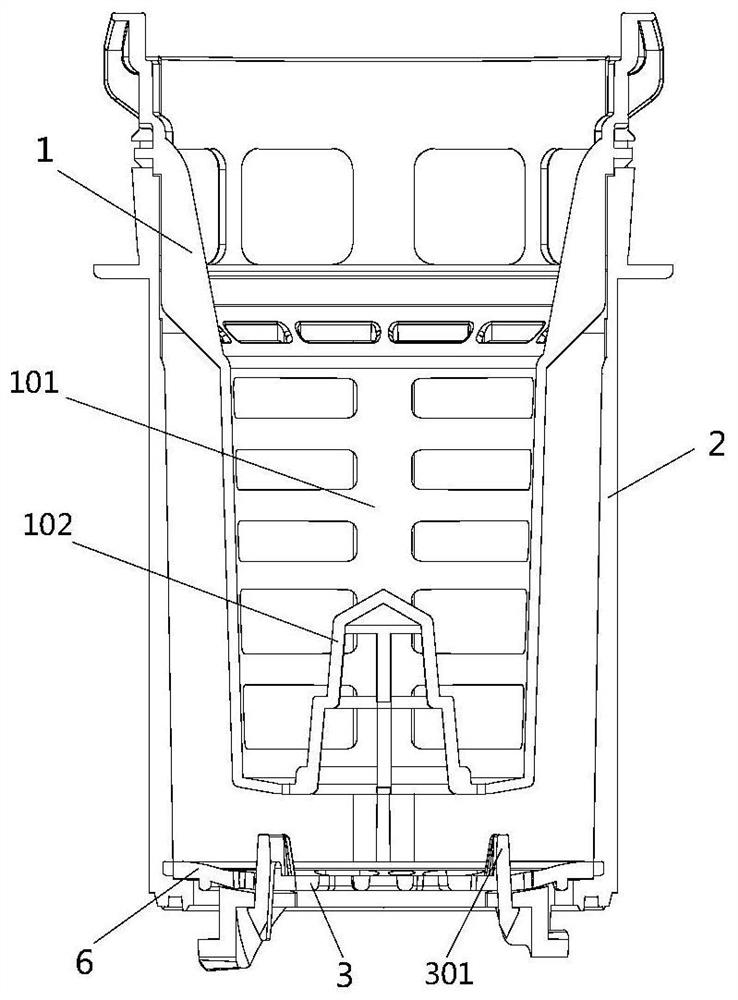

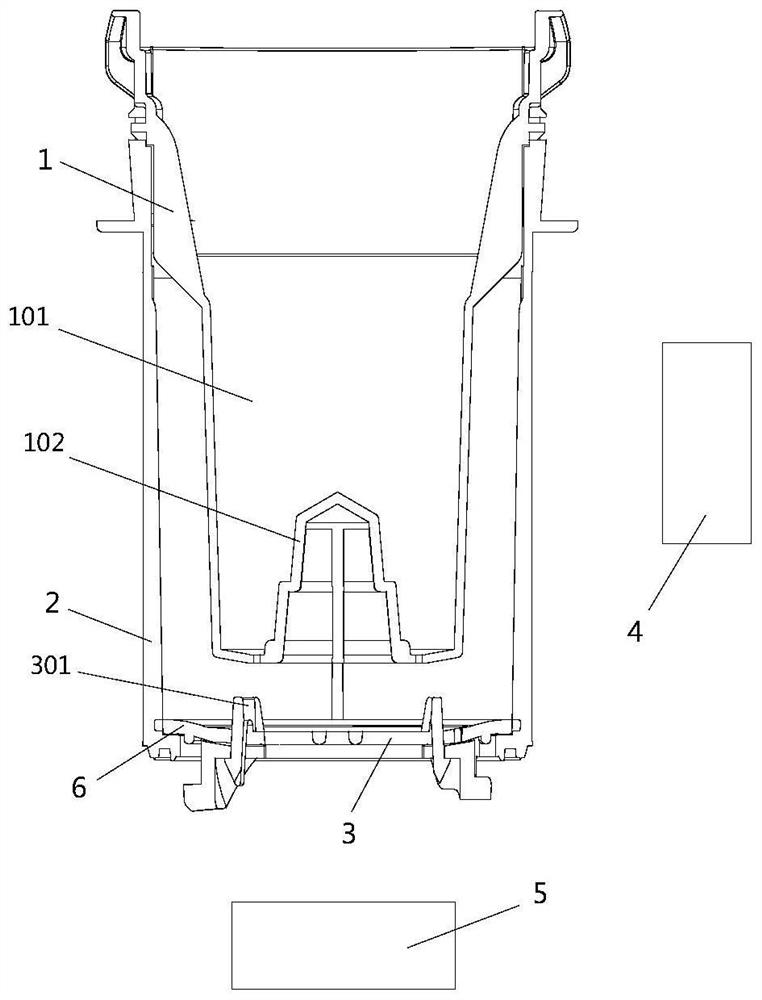

[0066] Such as Figure 1 to Figure 6 As shown, the filter system of a dishwasher described in this embodiment includes a circulating waterway and a draining waterway, and also includes at least three filtering parts; wherein, at least one filtering part is shared by the circulating waterway and the draining waterway; at least another A filter part cooperates with the filter part shared by the circulating waterway and the drainage waterway to form a filter system for the circulating waterway; at least one filter part cooperates with the filter part shared by the circulating waterway and the drainage waterway to form a filter system for the drainage waterway.

Embodiment 2

[0068] Such as Figure 1 to Figure 6 As shown, this embodiment is a further limitation of the first embodiment above. In this embodiment, a filter system for a dishwasher includes a first filter part 1, a second filter part 2 and a third filter part. Part 3; the first filter part 1 is at least partly placed inside the second filter part 2; the third filter part 3 is arranged on the side of the second filter part 2 close to the bottom; dishwashing The washing water in the machine flows into the first filter part 1 from the outside of the filter system; after passing through the first filter part 1, the washing water enters the second filter part 2; further, the circulating water A washing pump 4 is provided on the road; after the washing water in the dishwasher passes through the first filter part 1 and the second filter part 2, under the action of the washing pump 4, a circulating spray water is formed; further, A drain pump 5 is arranged on the drain waterway; after the wash...

Embodiment 3

[0071] Such as Figure 1 to Figure 6 As shown, this embodiment is a further limitation of the above-mentioned embodiment 1 or embodiment 2. In the filter system of a dishwasher described in this embodiment, at least a part of the first filter part 1 filters toward the second filter The part 2 is extended to form a holding tank 101 for containing impurities in the washing water; the holding tank 101 is provided with the raised structure 102 arranged toward the water inlet end of the first filter part 1; at least all The protruding structure 102 is provided with a structure for filtering washing water; further, the second filter part 2 is at least placed outside the receiving tank 101 of the first filter part 1; the second filter At least the side wall of the part 2 is provided with a structure for filtering washing water; the third filtering part 3 covers at least the bottom of the second filtering part 2 to form a filtering structure for filtering washing water flowing out of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com