Reducers and Robots

A technology of reducer and eccentric shaft, which is applied in the field of robotics, can solve the problems of improving the life of the whole machine that cannot be maximized, and achieve the effects of improving strength, prolonging service life, and prolonging the life of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

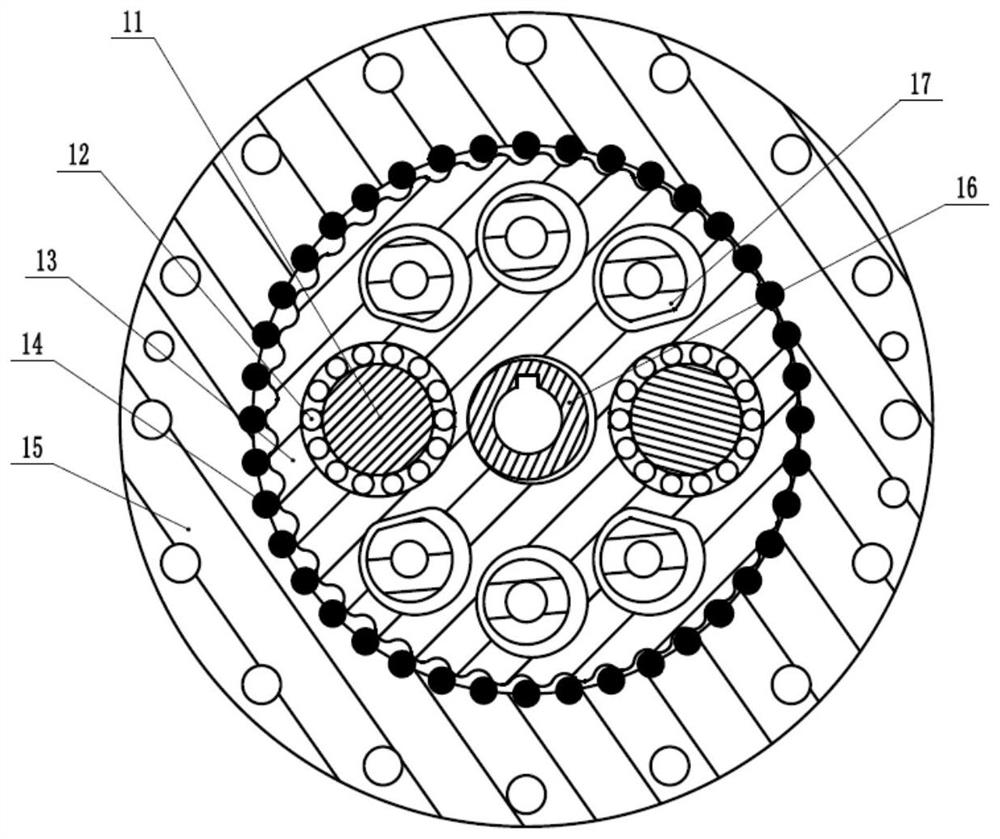

[0023] Fig. 1 is a cross-sectional view of the RV reducer complete machine, mainly showing the key components of the second-stage transmission of the RV reducer.

[0024] The RV reducer also includes a needle roller 14, a needle gear housing 15, an input shaft 16 and a support member 17, and the cycloidal wheel 13 is mounted on the needle gear

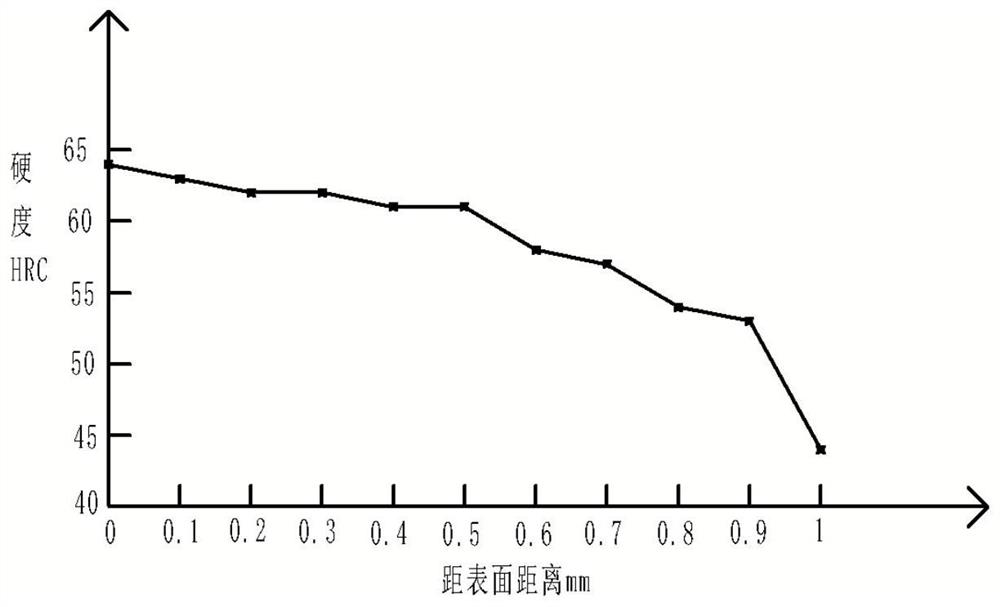

[0029] The surface of the eccentric shaft 11 adopts a carburizing heat treatment process for surface heat treatment.

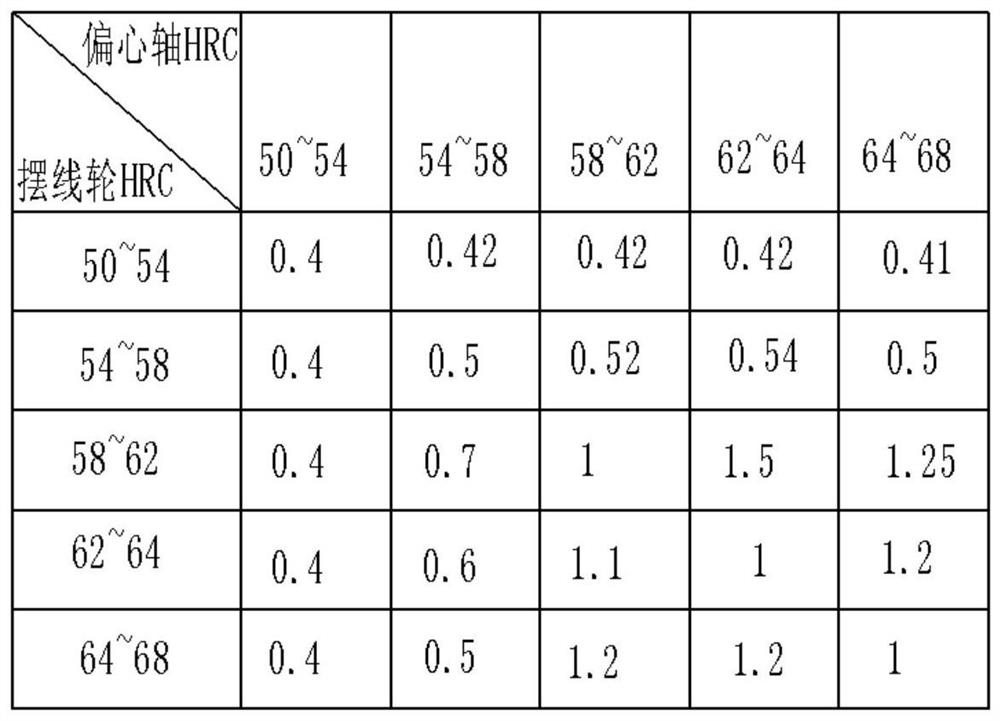

[0030] The surface hardness of the eccentric shaft 11 after heat treatment is 62HRC~64HRC. After heat treatment of the eccentric shaft 11 in the prior art

[0031] In one embodiment, the inner surface hardness of the shaft hole of the cycloidal wheel 13 after heat treatment is 58HRC˜62HRC.

[0033] The eccentric wheel and the cycloidal wheel 13 all use low carbon steel as the base material.

[0034] In this embodiment, according to the mass fraction, the iron of the low carbon steel includes 0.17% to 0.23% of C, and 0.17% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com