Movable decontamination foam generating device

A foam generating device, foam generator technology, applied in transportation and packaging, non-variable volume pumps, machines/engines, etc., can solve problems such as complex procedures, large space requirements, and inconvenient decontamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

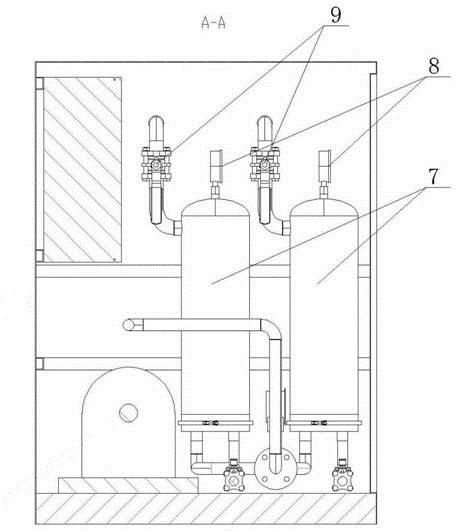

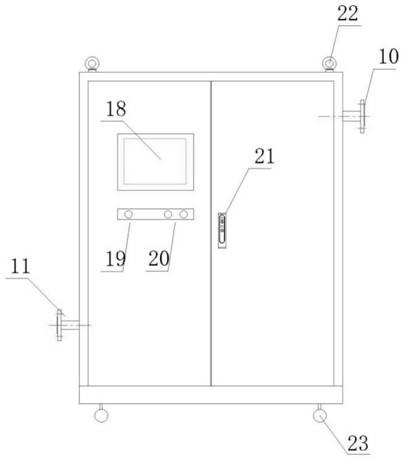

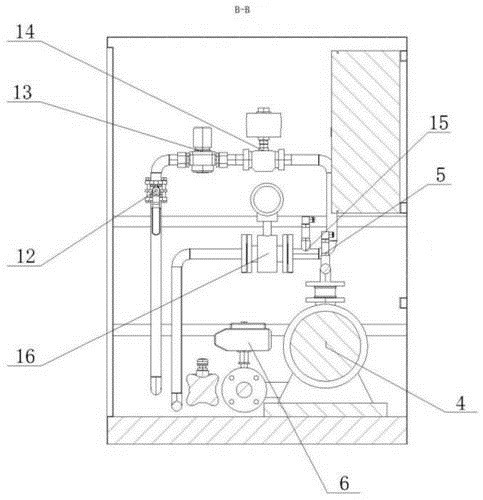

[0035] Refer to attached Figures 1 to 6 As shown, this embodiment provides a mobile decontamination foam generating device, which includes a housing, four universal wheels arranged under the housing, a control panel 18 arranged on the housing, and a Gas delivery unit, liquid delivery unit and foam delivery unit in The gas delivery unit includes gas inlet 11, gas manual control valve 12, gas electric control valve 14, gas pressure sensor 15, gas flow meter 16 and gas branch control valve 17, gas inlet 11, manual control valve, gas electric control valve 14 , the gas pressure sensor 15, the gas flow meter 16 and the gas branch control valve 17 are connected in series through the provided pipelines. The liquid delivery unit includes liquid inlet 1, liquid manual control valve 2, liquid electric control valve 3, liquid pressure sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com