Transmission shaft production line

A transmission shaft and production line technology, applied in static/dynamic balance testing, machine/structural component testing, and other manufacturing equipment/tools, etc., can solve the interference of multi-person operation, poor stability of the transmission shaft, affecting product quality and output And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

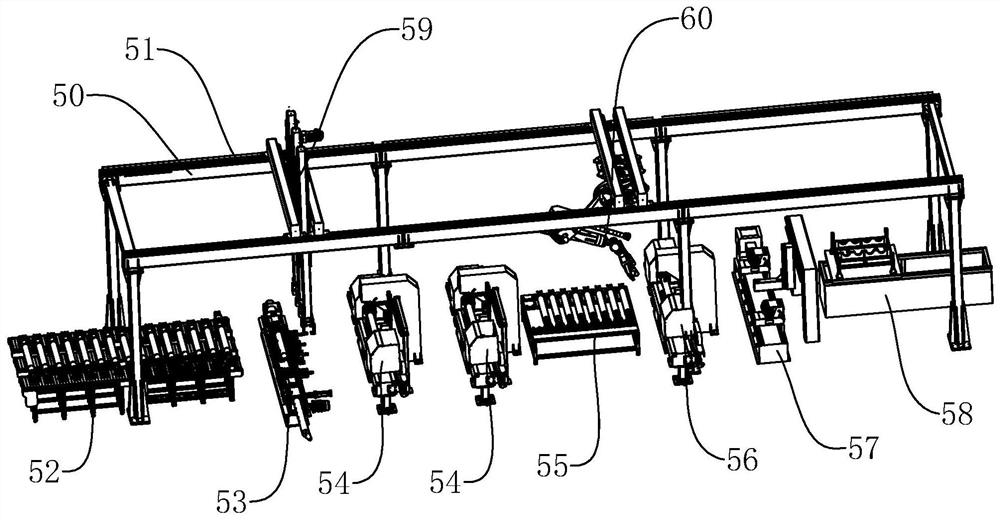

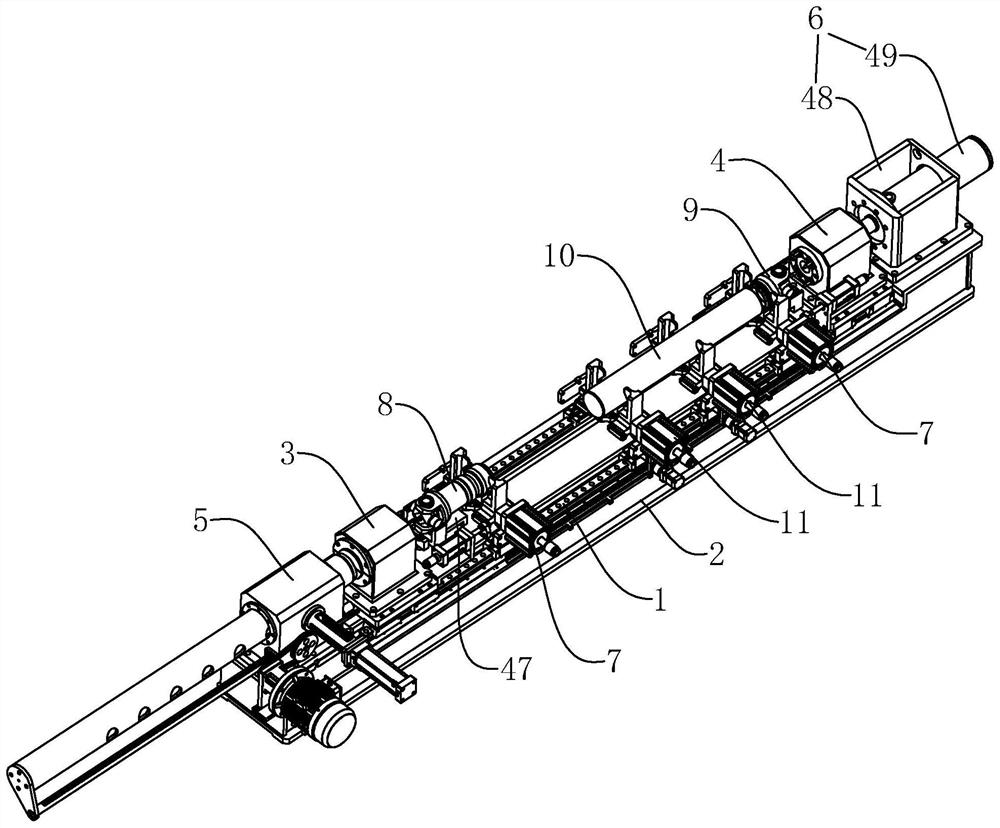

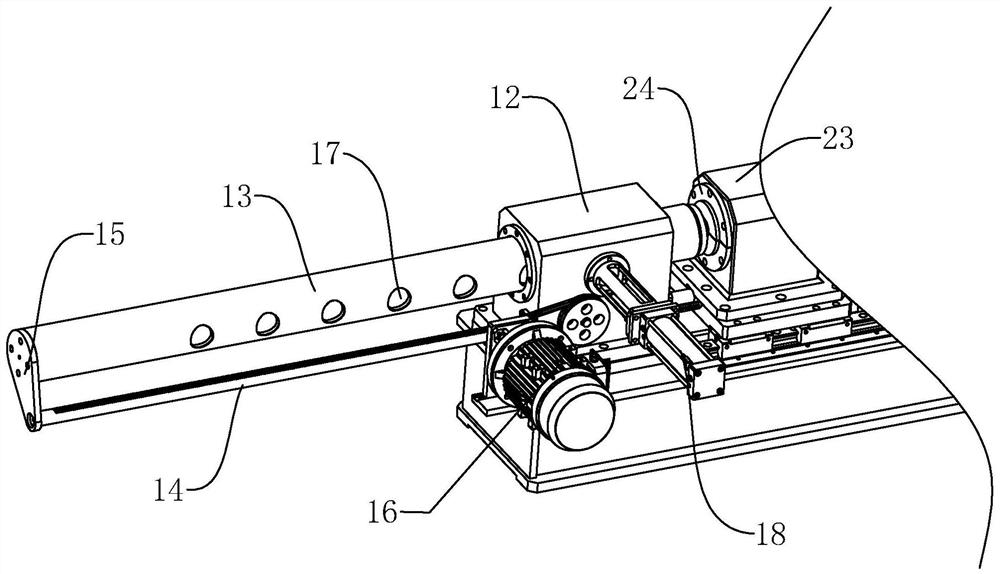

[0041] Such as figure 1 As shown, a transmission shaft production line includes a truss 50 and a slideway 51 arranged on the truss 50 . Below the truss 50, there are three-part transmission mechanism 52, drive shaft pressing machine 53, straightening and welding machine 54, mid-end cooling transmission frame 55, straightening machine 56, dynamic balancing machine 57 and product output transmission frame arranged in sequence from left to right. 58. The three-part conveying mechanism 52 is used to convey the drive shaft head 8 , the drive shaft tube 10 and the drive shaft tail 9 to the drive shaft pressing machine 53 side respectively.

[0042] The slideway 51 is slidably provided with a first transfer mechanism 59 that can simultaneously transfer the transmission shaft head 8, the transmission shaft tube 10 and the transmission shaft tail 9 on the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com