Logistics tray

A pallet and logistics technology, applied in the field of logistics equipment, can solve the problems of fork groove wear and damage, items slipping, uneven fork groove unevenness, and achieve the effect of reducing wear, avoiding stress damage, and facilitating access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

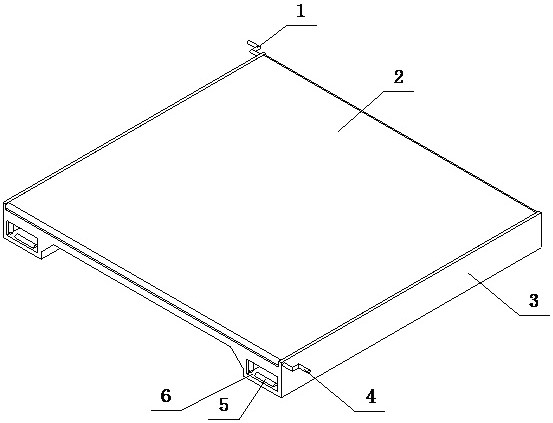

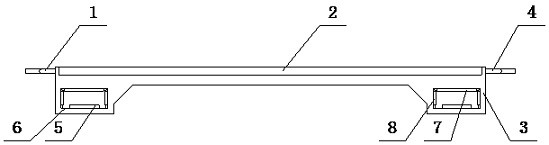

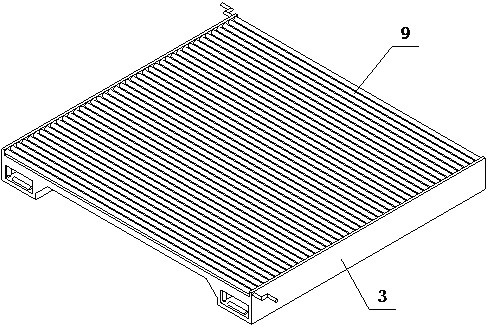

[0016] A logistics pallet of the present invention is realized in the following way: a logistics pallet of the present invention is composed of a rear crank (1), a belt (2), a tray main body (3), a front crank (4), a bottom roller (5), a forklift Groove (6), top roller (7), side roller (8), support roller (9), roller shaft (10), spring (11), roller frame (12) and sliding frame (13), the tray The main body (3) is respectively provided with forklift slots (6) near both ends, and a plurality of bottom rollers (5) are equidistantly placed at the bottom of the forklift slots (6), and the forklift slots (6) are built with roller racks (12 ), the roller frame (12) is an inverted U-shaped frame composed of a horizontal bar and two vertical bars, the top roller (7) is placed on the horizontal bar, and the side roller (8) is placed on the side bar. A plurality of roller racks (12) are equidistantly distributed in the forklift groove (6) and are connected by two sliding frames (13). Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com