Continuous rope-shaped dyeing washing machine and operation method thereof

A washing machine and rope-shaped technology, which is applied in the field of fabric dyeing and washing equipment, can solve the problems of large amount of waste water, long time consumption, long time consumption and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

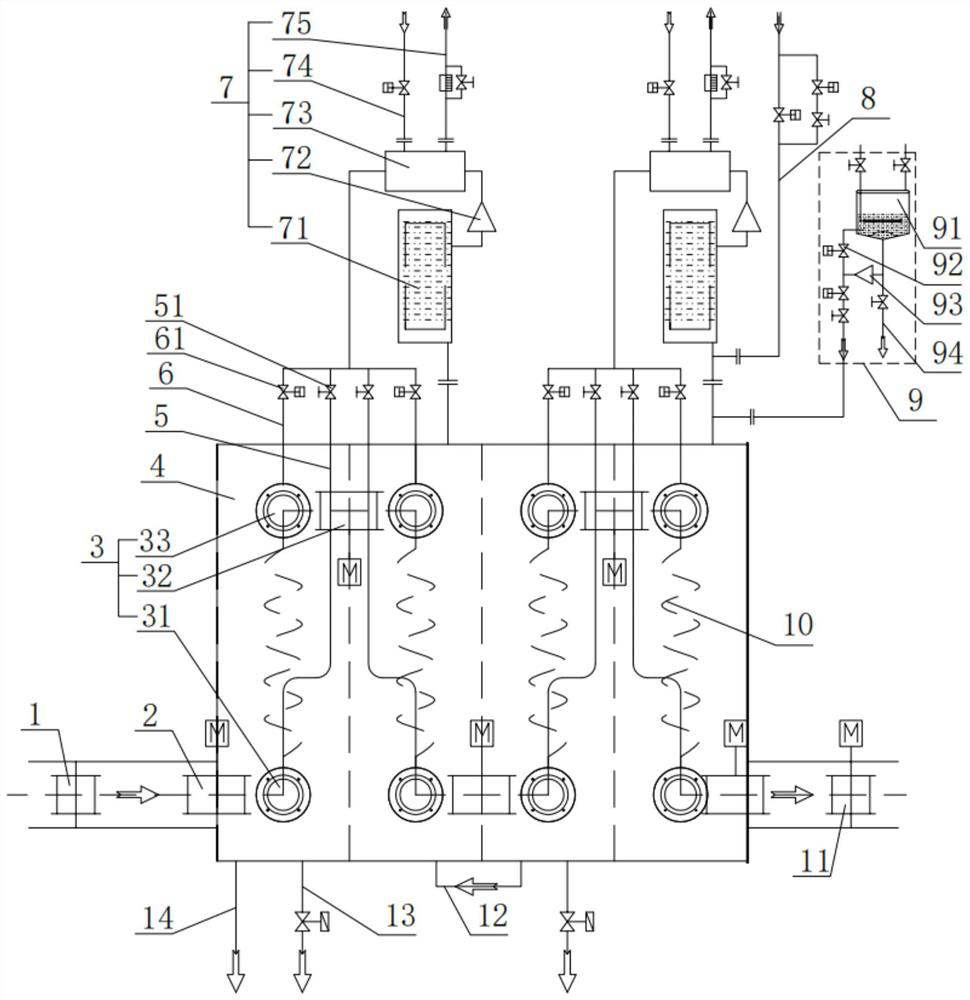

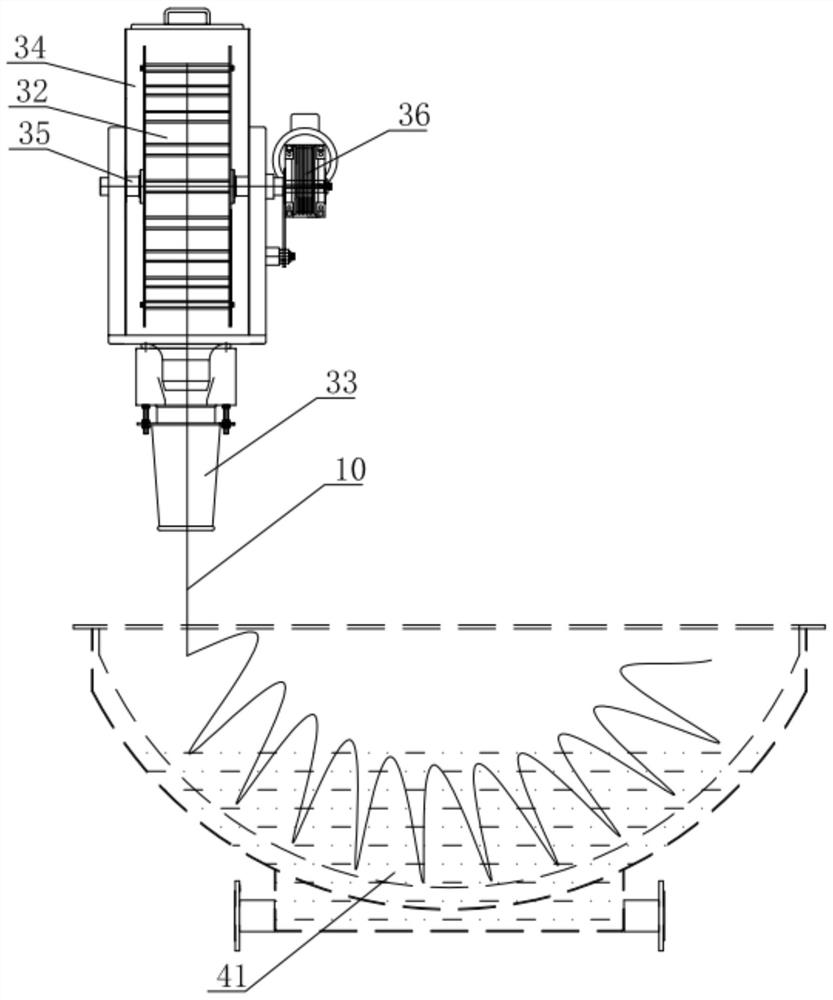

[0031] Such as figure 1 As shown, the continuous rope dyeing washing machine of this embodiment includes two or more water tanks 4 arranged side by side, each of which is equipped with the same water washing unit 3; the front end of the first water tank 4 outside the wall A cloth feed wheel 1 is installed, and a cloth discharge wheel 11 is installed on the front end outside the wall of the last tank 4, between the cloth feed wheel 1 and the first washing unit 3, between adjacent washing units 3, and the last washing unit 3 A press wheel 2 is installed between the cloth output wheel 11; a single washing unit 3 includes a cloth lifting wheel 32 installed above the rear end of the corresponding water tank 4; through the transmission of the cloth feeding wheel 1, the fabric 10 enters each washing unit 3 in turn Afterwards, it is exported thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com