Air treatment device for coal mine operation

An air treatment device and coal mine technology, which is applied in the field of coal mine operations, can solve problems such as easy to speed up mining, aging of transportation equipment, general dust removal effect, and health effects of workers, so as to improve air treatment quality, prolong water washing time, and ensure The effect of washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

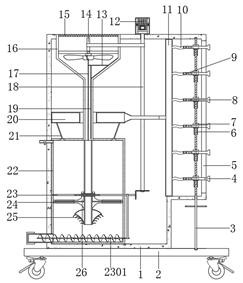

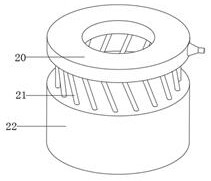

[0029] refer to Figure 1-4 , an air treatment device for coal mine operations, comprising a base 2 with brake wheels fixed to the four corners of the bottom outer wall by bolts, a main casing 1 is fixedly installed on the top outer wall of the base 2, and a main casing 1 is fixedly installed on one side of the inner bottom of the main casing 1 Water washing box 22, and the top of main housing 1 is welded with the inlet end barrel 16 that is connected with water washing box 22, and the bottom end of inlet end barrel 16 is equipped with gas distribution mechanism, and gas distribution mechanism includes being connected to by bearing rotation. The movable baffle 26 of the air intake end cylinder 16, the end of the air intake end cylinder 16 close to the movable baffle 26 is fixedly installed with a fixed end plate 24, and the opposite side of the fixed end plate 24 and the movable baffle 26 are provided with corresponding openings. The gas-emitting groove 29, the bottom outer wa...

Embodiment 2

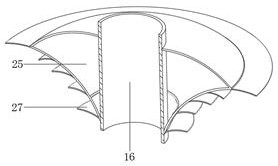

[0039] refer to Figure 5 , an air treatment device for coal mine operations. Compared with Embodiment 1, this embodiment also includes an extension sleeve 33 that is welded to the top of the movable shutter 26 and is rotatably connected to the intake end cylinder 16, and the outer wall of the extension sleeve 33 The spiral deflector 30 is fixedly installed; the extended sleeve 33 provided can rotate with the movable shutter 26, and utilizes the continuous rotation of the spiral deflector 30 to drive the liquid containing air bubbles downward, further Extend the water wash time of the gas.

[0040] In the present invention, the spiral deflector 30 is provided with equidistant spirally distributed gas ports 31, and the spiral deflector 30 is fixedly equipped with equidistantly distributed rotating filter screen ends 32; the fully washed gas can pass through due to its own density reduction. The air port 31 is quickly exported; the rotating filter end 32 rotates with the extens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com