Paver spiral blade and paver

A technology of spiral blades and paver, which is applied in the direction of roads, road repairs, roads, etc., and can solve the problems of short service life, high quality, and low conveying efficiency of spiral blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

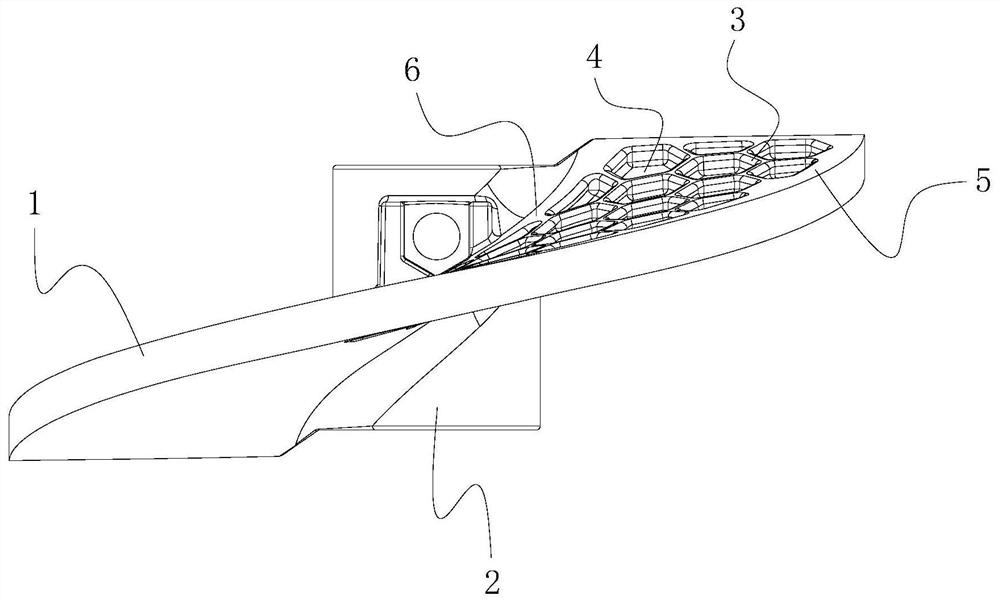

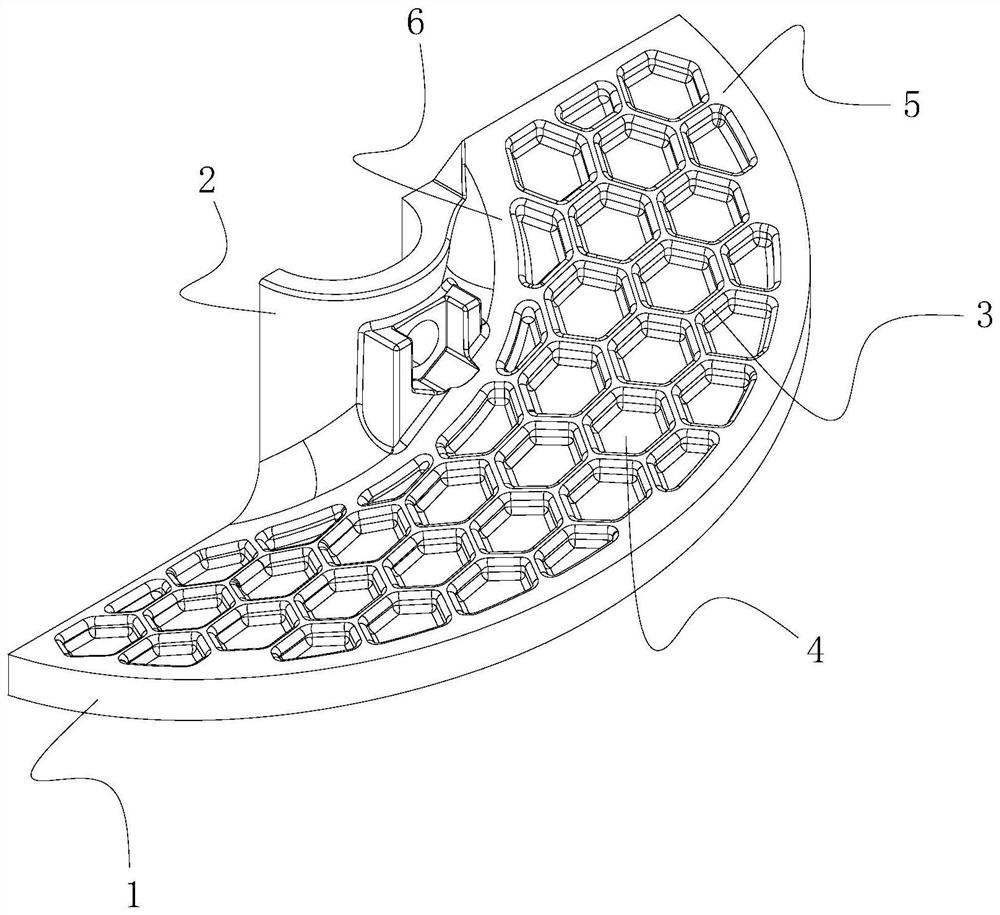

[0022] see figure 1 with figure 2 , a spiral blade of a paver, comprising a blade body 1 and a connecting body 2 arranged on one side of the blade body. In this embodiment, the blade body 1 and the connecting body 2 are cast as one piece. The connecting body 2 is in the shape of a bearing bush. The connecting body 2 is provided with holes for installing locking bolts.

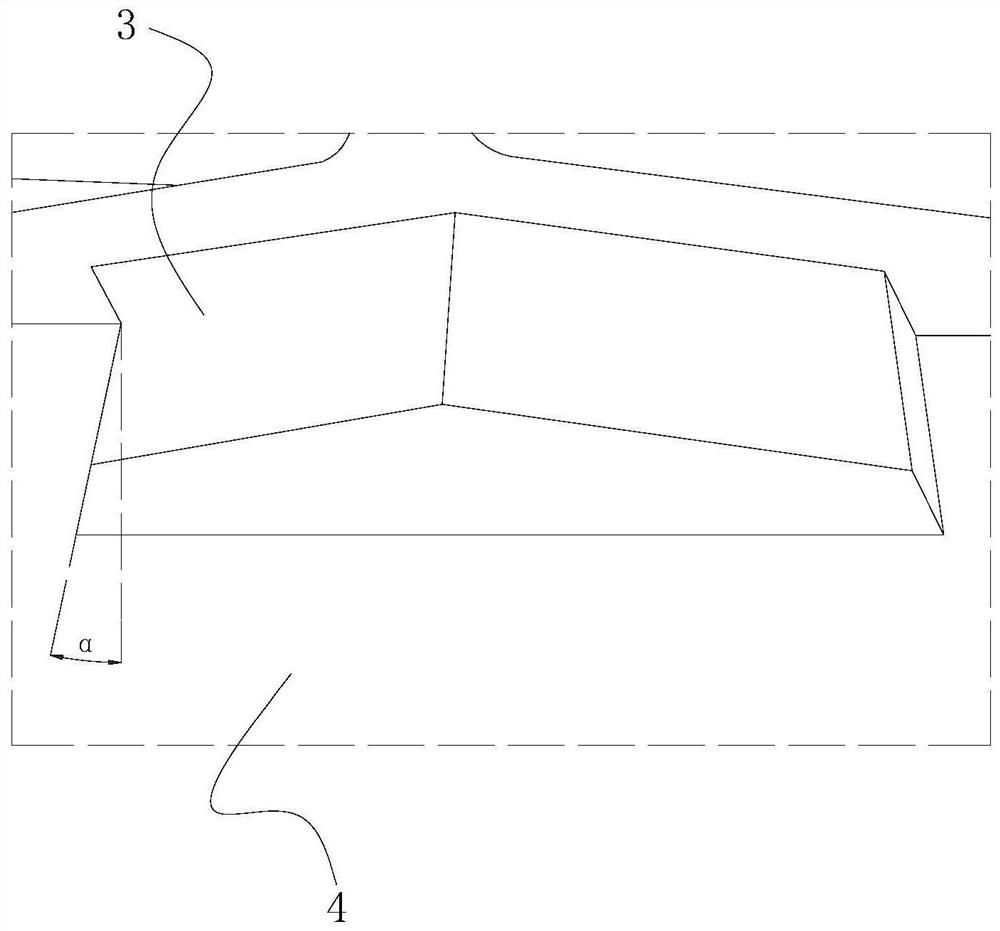

[0023] The blade body 1 includes a back surface and a material guiding surface opposite to the back surface. The material guide surface is the surface in the same direction as the material conveying direction, and is the action surface between the blade body 1 and the material. The grid-like ribs 3 are arranged on the material guiding surface, and the grid-like ribs 3 form several grooves 4 on the material guiding surface. In this embodiment, the grid-like ribs 3 and the blade body 1 are integrally cast. The transition between the grid-like ribs 3 and the material-guiding surface of the blade body 1 adop...

Embodiment 2

[0027] A paver equipped with any one of the above-mentioned helical blades. That is, the paver has a rotatable paving shaft. A plurality of said helical blades are fixedly installed on the paving rotating shaft by screws, and the helical blades form helical blades from one end of the paving rotating shaft to the other end.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap