Supporting structure combining anti-seepage structure and underground diaphragm wall and construction method thereof

A technology of underground diaphragm wall and supporting structure, which is applied in basic structure engineering, protection devices, gaskets, etc., can solve the problems of complex structure, many construction processes, and many additional materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail in the form of embodiments in conjunction with the accompanying drawings.

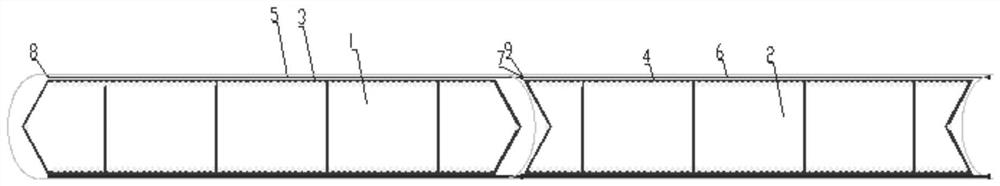

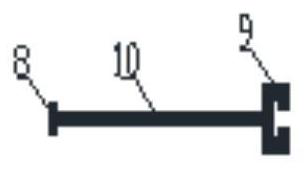

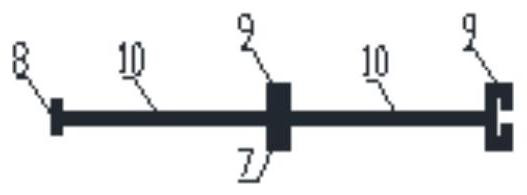

[0017] At the foundation pit enclosure construction site, the supporting structure of the present invention is composed of the first excavation section 1 of the underground diaphragm wall and the anti-seepage structure 5 welded on the reinforcement cage 3 of the first excavation section, and the rear excavation section 2 of the underground diaphragm wall and The anti-seepage structure 6 welded on the reinforcement cage 4 of the post-grooving section is composed of the seepage-proof structure 5 of the first-grooving section and the anti-seepage structure 6 of the post-grooving section. Locked by a bolt 8, a geomembrane 10 is arranged between the lock 9 and the bolt 8. The overlap between the anti-seepage structure 5 of the groove-digging section and the anti-seepage structure 6 of the groove-digging section is completed by the interlocking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com