Inertial positioning method for steam turbine jigger

An inertial positioning and steam turbine technology, applied in the field of inertial positioning of steam turbine barring, can solve problems such as cumbersome, gear wear, and uncontrollable rotation angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail below in conjunction with accompanying drawing.

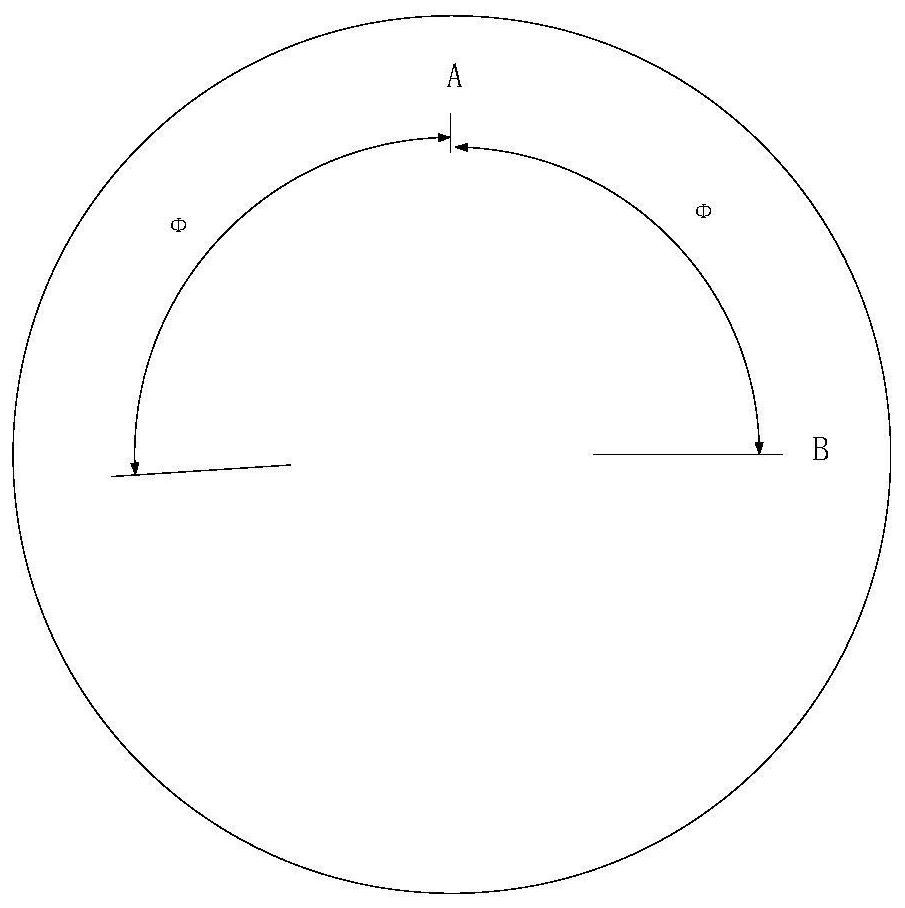

[0016] see figure 1 , an inertial positioning method for a steam turbine barring, specifically comprising the following steps:

[0017] Step 1. Straighten the large shaft of the steam turbine: start the lubricating oil and jacking oil system of the steam turbine cranking, and wait for the steam turbine jacking oil system to run stably, that is, when the oil pressure has no band and there is no leakage on site, start the cranking Start continuous cranking on the control cabinet until the eccentricity of the major shaft falls within the rated range (≤20μm);

[0018] Step 2. Preset a barring stop point A, crank for multiple turns continuously, and then stop barring at this point. When the main shaft of the steam turbine stops completely, record the stop point of the main shaft of the steam turbine and the preset stop point. The deflection angle Φ of point A is based on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com