Fractal gradient cap-shaped composite structure

A composite structure and fractal technology, applied in the substructure, superstructure, subassembly of the superstructure, etc., can solve the problem of not being able to further strengthen the crashworthiness of the hat-shaped structure, large force at the moment of collision, and small peak impact to improve material utilization efficiency, transmit force well, and optimize crashworthiness performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

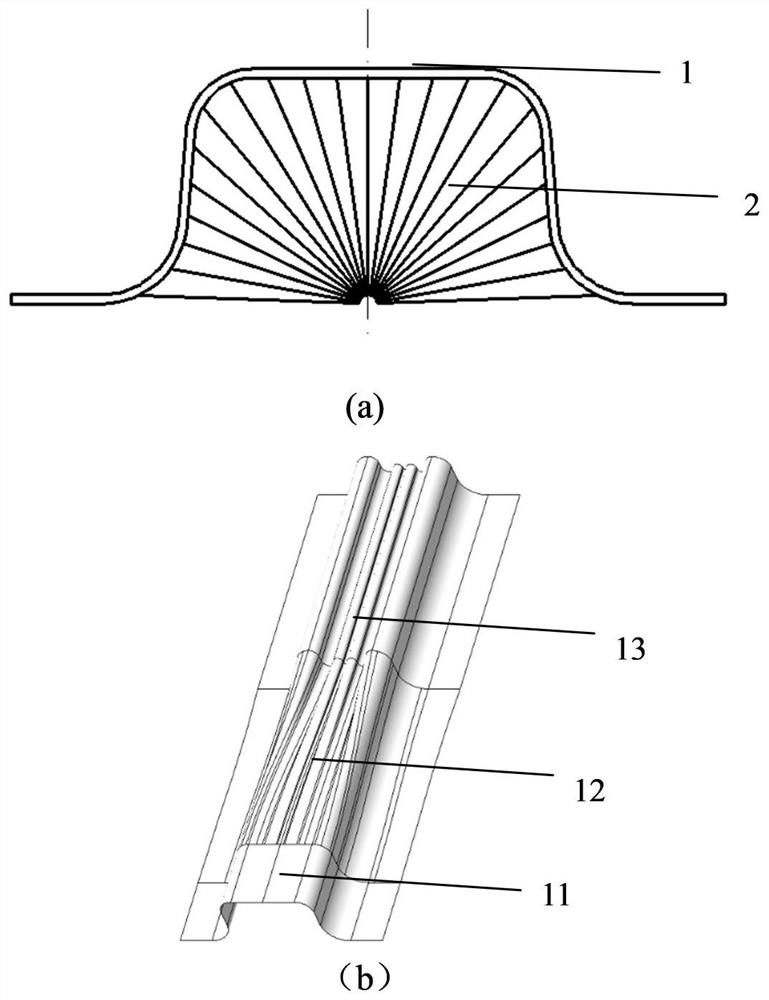

[0041] figure 1 (a) is a schematic composition diagram of a fractal gradient hat-shaped composite structure, which is composed of an external hat-shaped structure 1 and a fan-shaped honeycomb structure 2 surrounded by it; (b) is a three-dimensional schematic diagram of a fractal gradient hat-shaped structure, according to the cap Geometry of the roof A structure is mainly composed of three parts: planar region 11 , transition region 12 , and fractal region 13 .

[0042] The cap top of the plane area 11 is divided into common flat surfaces at present, which can reduce the continuous increase of the impact force.

[0043] The main function of the transition zone 12 is to prevent the stress concentration and force sudden change caused by the discontinuous geometric change. Realize the progressive fractal continuous transition of the planar area 11 and the frac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com