Sound insulation and noise reduction device for wall-penetrating pipeline in hydropower plant

A technology for hydropower plants and pipelines, applied in the direction of pipes, pipe components, electrical components, etc., can solve the problems of inconvenient sound insulation, affecting the working environment of the workshop, and loud noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

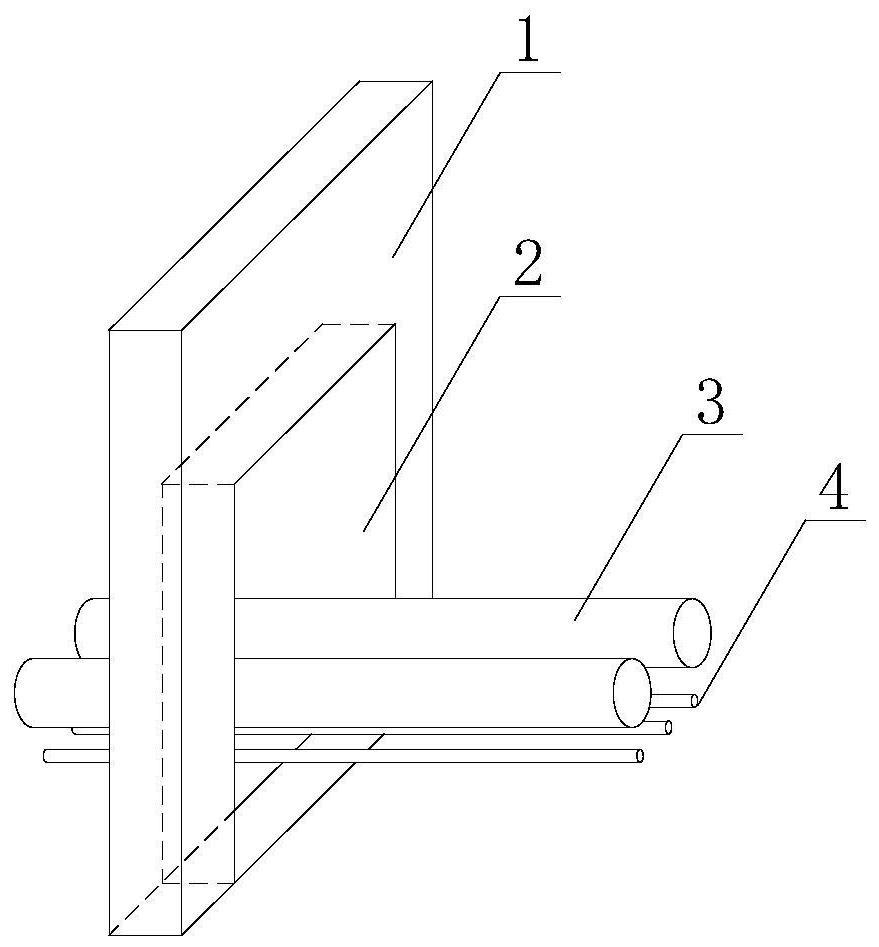

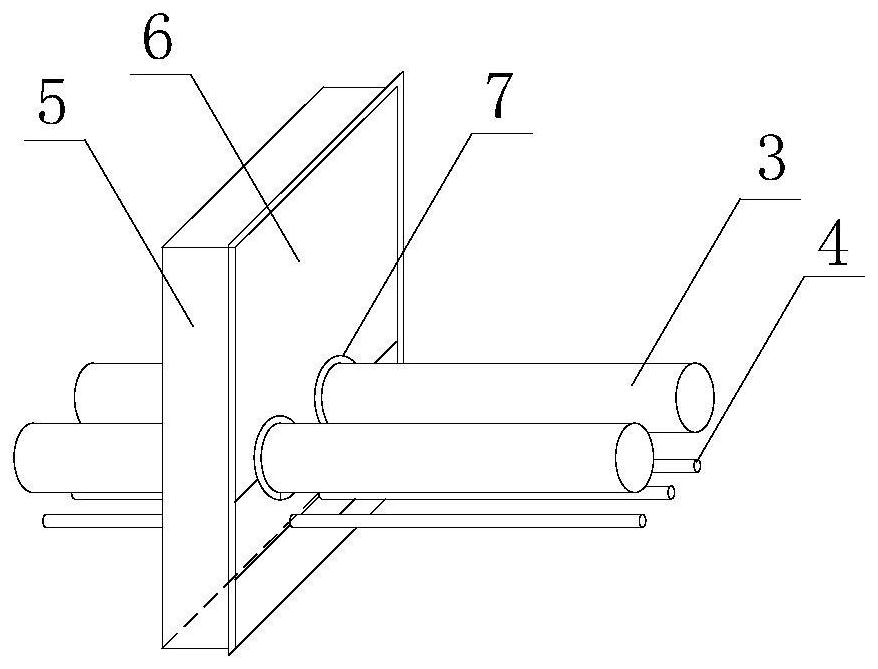

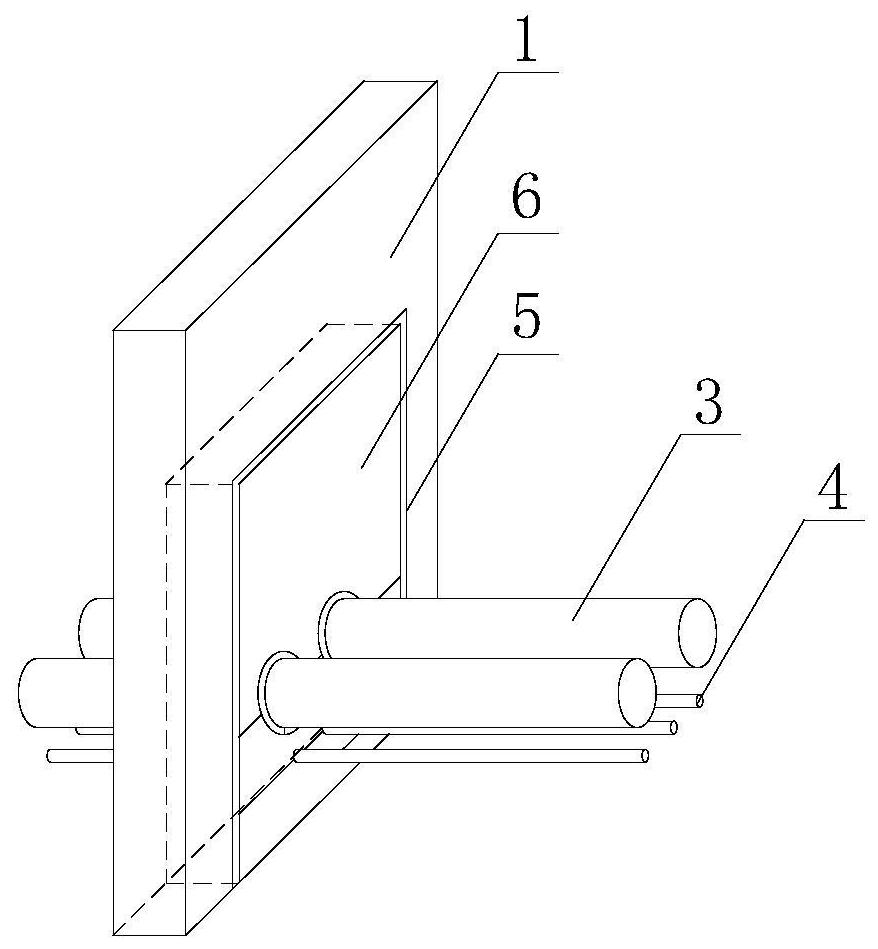

[0020] Embodiment 1: see Figure 1 to Figure 6 , a sound insulation and noise reduction device for wall-penetrating pipelines in hydropower plants, including a wall 1 to be installed, the wall 1 is provided with a channel opening 2 for the passage of wall-penetrating pipelines, and the sound insulation and noise reduction device is also included. The sound insulation and noise reduction device is composed of a sound insulation and noise reduction board 6 and an installation frame 5, the sound insulation and noise reduction board 6 is set upright, and is embedded in the channel opening 2 of the wall 1 through the installation frame 5, and the sound insulation and noise reduction board 6 To block the channel opening 2, the installation frame 5 plays the role of installing and fixing the sound insulation and noise reduction board 6.

[0021] A through hole a64 is provided between the upper plate body 61 and the middle plate body 62 to facilitate the passage of the large pipe 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com