An online diagnosis device and method for the status of the shafting power system of a hydraulic turbine unit

A technology of power system and diagnosis method, applied in the direction of measuring device, electric device, electromagnetic measuring device, etc., can solve the problem of inability to monitor the working state of the shafting power system, the establishment of the thickness of the lubricating water film cannot be known, and the lifting of the spindle seal ring. Insufficient height, etc., to ensure long-term safe operation, avoid heat and even wear, reduce workload and work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is described in detail below in conjunction with accompanying drawing:

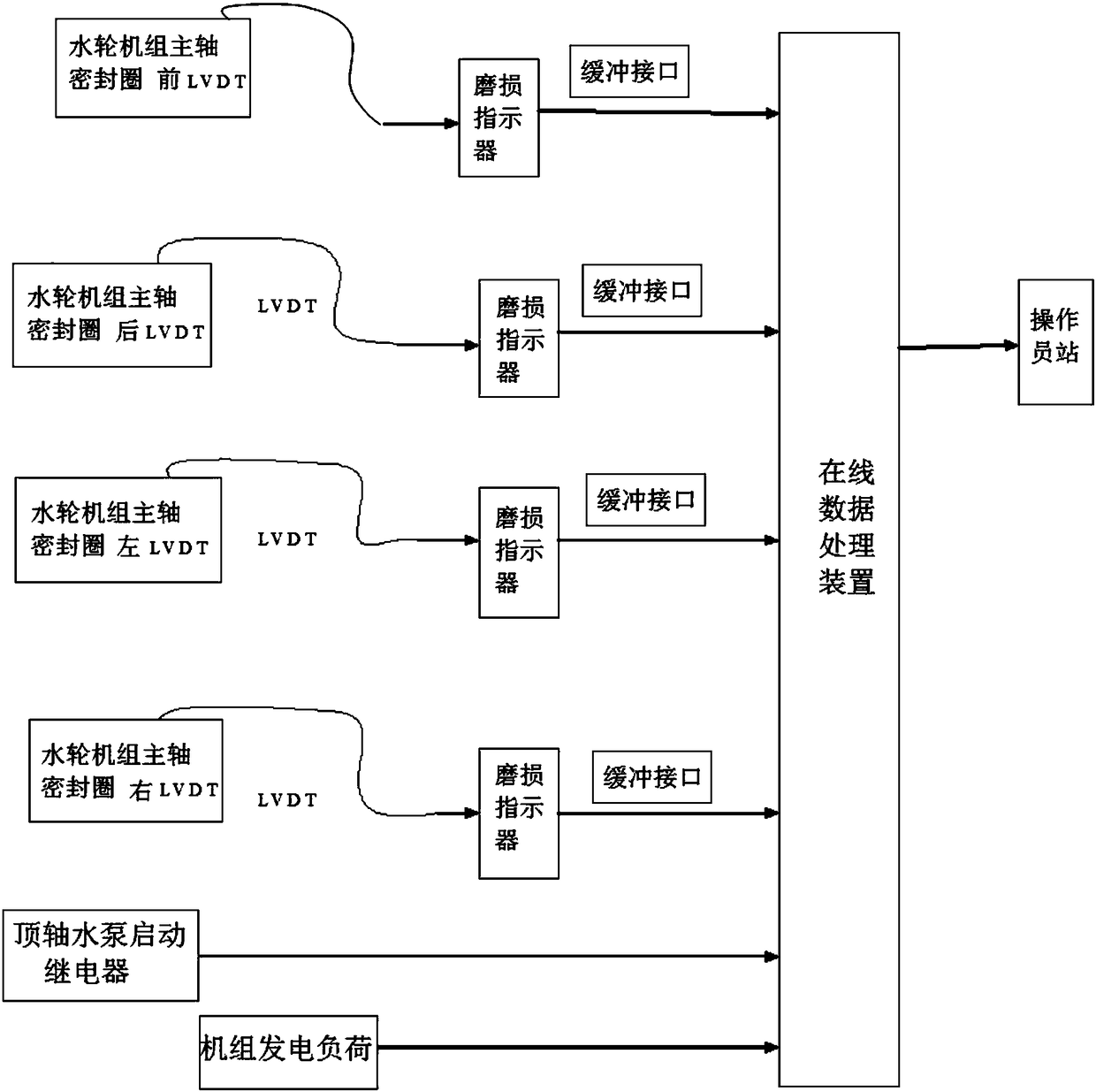

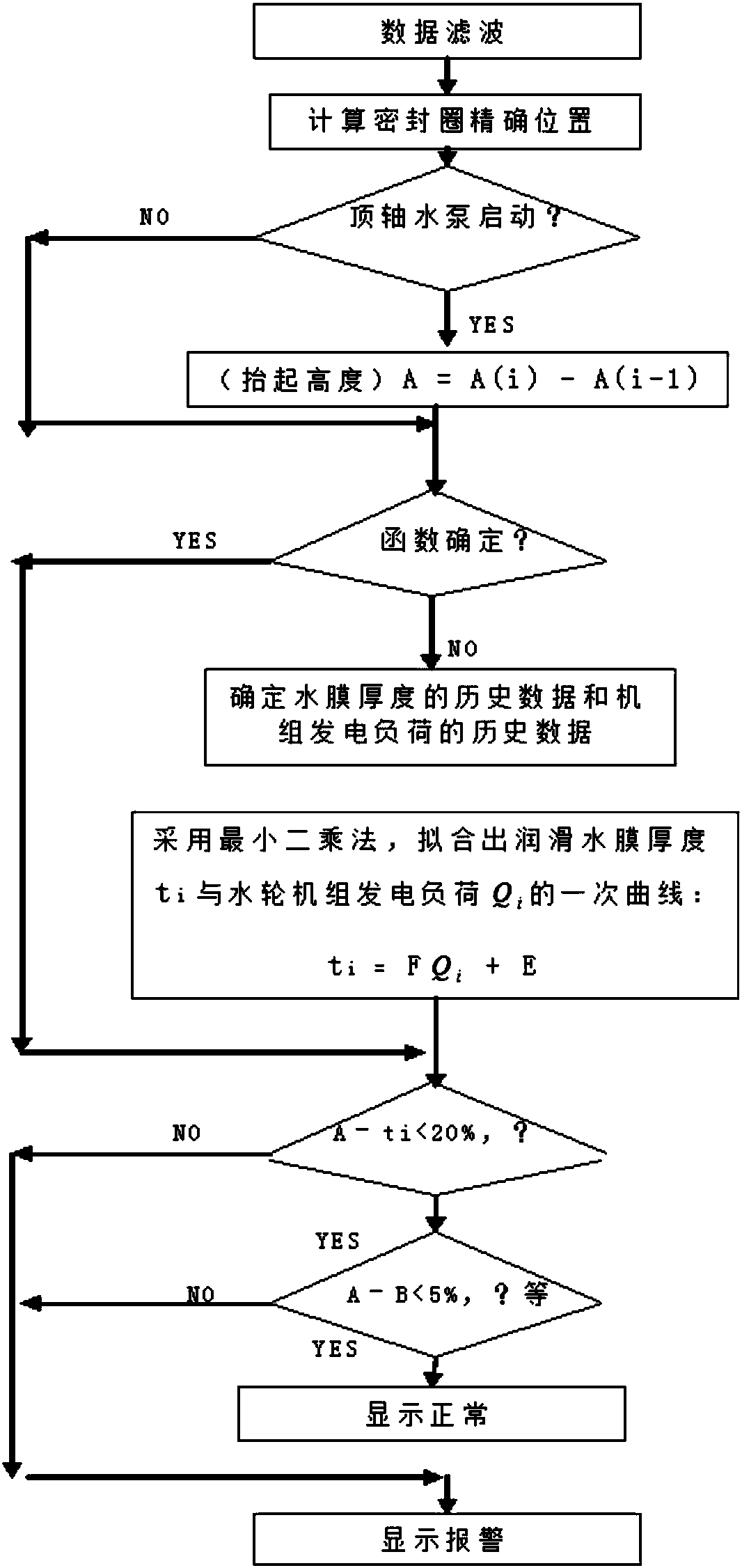

[0045] like figure 1 As shown, an online diagnostic device for the state of the shafting power system of a hydraulic turbine unit includes: a hydraulic turbine LVDT sensor, a wear indicator and an online data processing device;

[0046] LVDT sensors (differential transformers) are installed inside the turbine unit to measure the wear of the main shaft seal ring of the turbine unit; each LVDT sensor is connected to a wear indicator, and the LVDT sensor transmits the wear signal of the main shaft seal ring to the wear indicator. The wear indicator is connected to the on-line data processing device through the output buffer interface, and the on-line data processing device is connected to the operator station installed on the operating table of the central control room of the power station.

[0047] When the unit is running, the wear indicator monitors the size of the wear sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com