Plasma processing method and plasma processing device

A technology of plasma and treatment method, applied in the field of plasma treatment and plasma treatment device, can solve the problems of low ion energy and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Various exemplary embodiments will be described below.

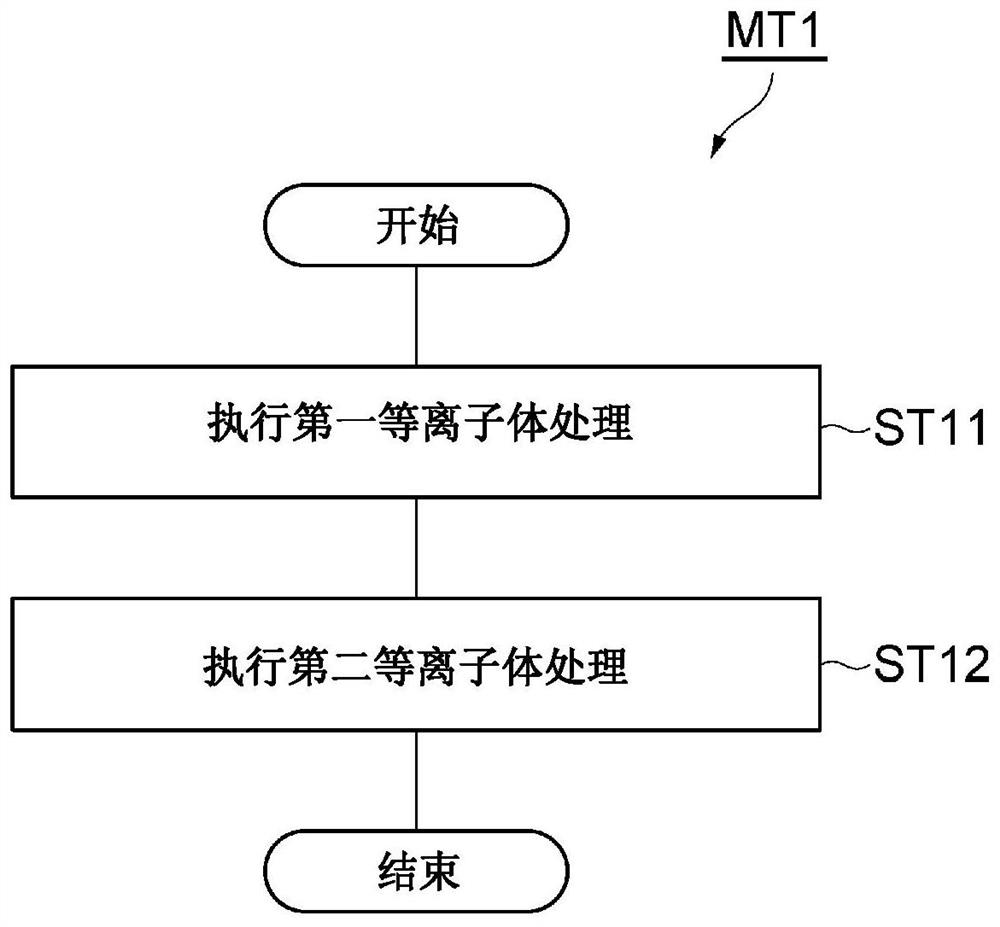

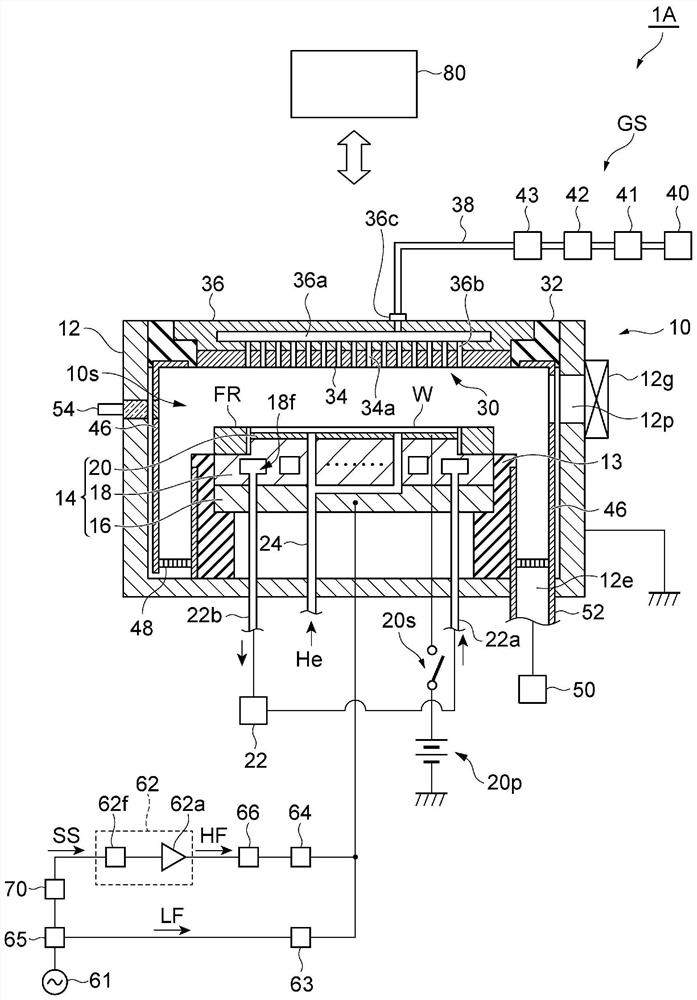

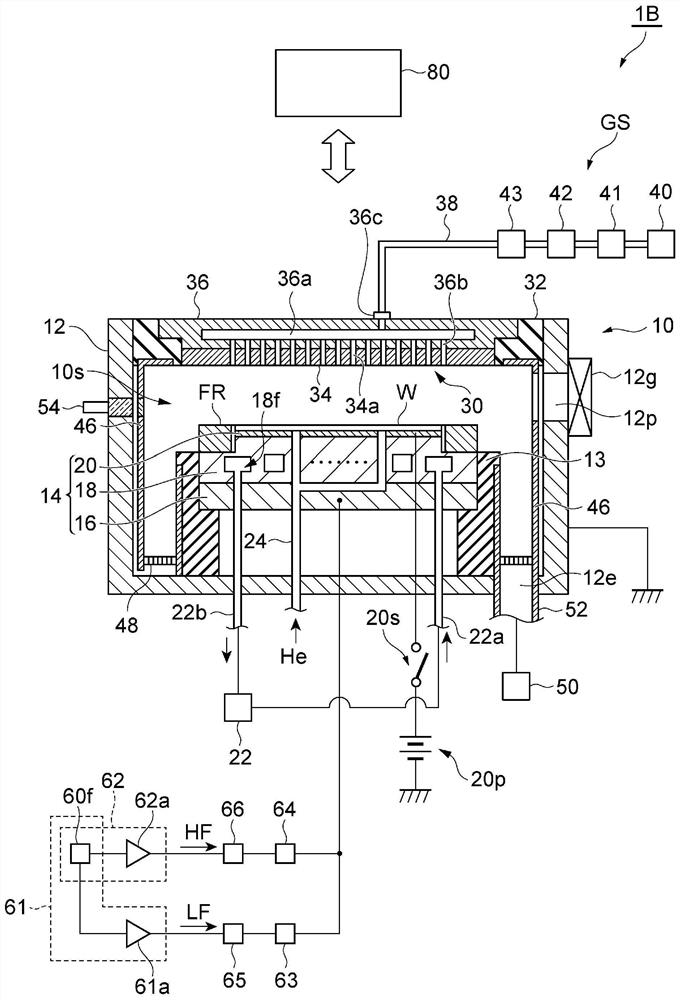

[0038] According to an exemplary embodiment, a plasma processing method is provided. The plasma processing method includes the steps of performing a first plasma treatment in a chamber during a first period; and performing a second plasma in a chamber after the first period or in a second period following the first period. processing steps. In the step of performing the first plasma treatment and the step of performing the second plasma treatment, the first high-frequency power is continuously supplied to the lower electrode of the substrate support table. The first high-frequency power has a first frequency. A substrate support table is disposed within the chamber. The second high-frequency power is supplied as pulsed high-frequency power during the first partial period of the first period and the second partial period of the second period. The second high-frequency power is high-frequency power having a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com