Ruthenium coordinated polypyrrole nanosphere cluster material and preparation method and application thereof

A pyrrole nano-coordination technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of poor long-term cycle stability, poor high-power discharge performance, and limited application of polypyrrole, so as to improve cycle stability, improve conductivity, improve The effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

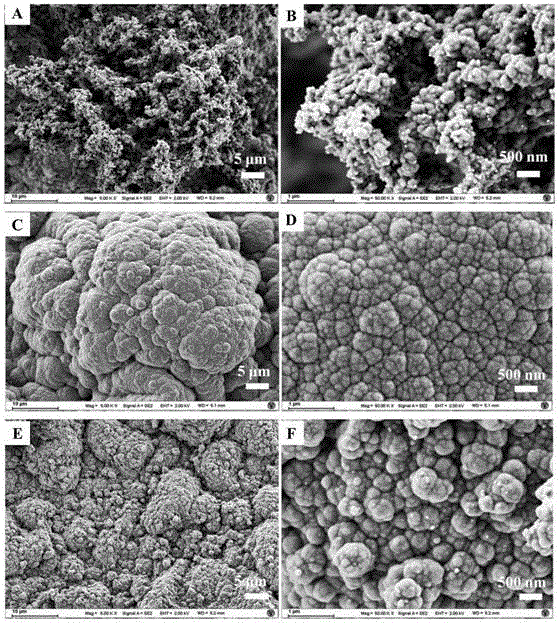

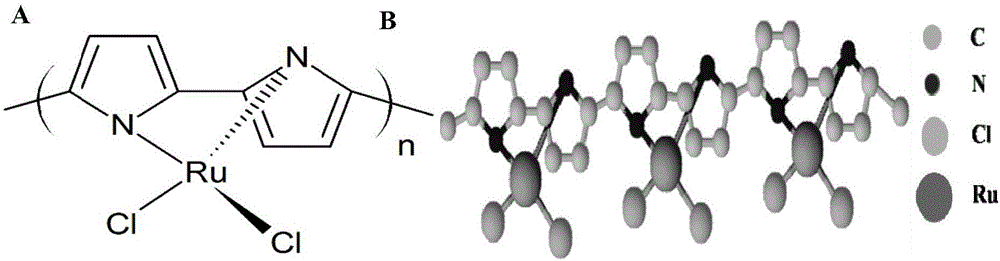

[0039] For the molecular formula and structural schematic diagram of the ruthenium-coordinated polypyrrole material described in the present invention, please refer to the attached description for details. figure 1 . Utilize the interaction between the vacant orbit of the ruthenium ion and the unpaired electrons of the nitrogen atom on the pyrrole chain to coordinate to obtain the monomer complex pyrrole ruthenium; and then electrochemically polymerize to obtain the coordination polymer. The molecular structure of ruthenium-coordinated polypyrrole is tetrahedral. The schematic diagram of the spatial structure of the ruthenium-coordinated polypyrrole nanosphere cluster material of the present invention, see the attached Figure 16 , it can be seen that it is mainly composed of ruthenium-coordinated polypyrrole nanospheres 1 , the nanospheres are closely packed to form nanosphere clusters 2 , and the nanosphere clusters are aggregated to form micropores 3 between nanosphere clu...

Embodiment 2

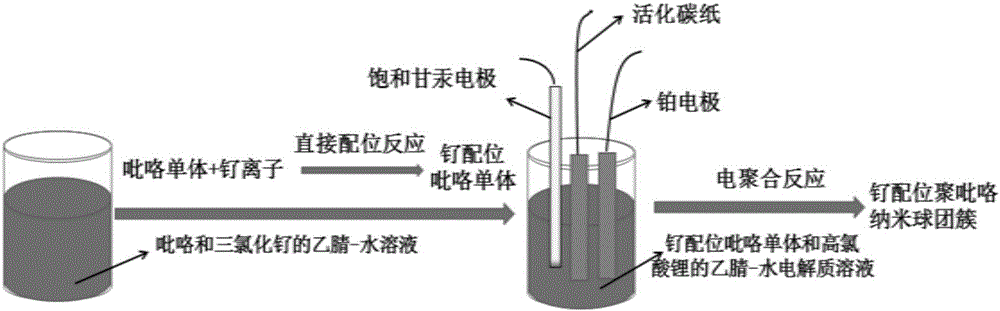

[0041] The preparation process flow chart of the ruthenium-coordinated polypyrrole nanosphere cluster material described in the present invention is detailed in the appendix of the description figure 2 . The specific preparation steps of the ruthenium-coordinated polypyrrole material are as follows:

[0042] (1) Using the acetonitrile / water solution of pyrrole monomer and ruthenium trichloride as the reaction solution, using the empty orbital of the ruthenium ion and the unpaired electron interaction of the nitrogen atom on the pyrrole chain, direct coordination reaction at room temperature to obtain the pyrrole monomer The complex with ruthenium ions coordinates the pyrrole monomer with ruthenium.

[0043] (2) In the electrochemical three-electrode system, activated carbon paper is used as the electrode base material and as the working electrode, the platinum sheet is used as the auxiliary electrode, and the saturated calomel electrode is used as the reference electrode, an...

Embodiment 3

[0046] The specific preparation method of the ruthenium-coordinated polypyrrole nanosphere cluster electrode material of the present invention is as follows:

[0047] (1) The static coordination method: using the acetonitrile / water solution of pyrrole monomer and ruthenium trichloride as the reaction solution, the volume ratio of acetonitrile / water is 1:3, and the molar concentration of pyrrole monomer is 0.1mol / L , the molar concentration of ruthenium trichloride is 0.0003mol / L, the coordination reaction time is 12h, and the reaction temperature is 25°C.

[0048] (2) The described cyclic voltammetry electropolymerization method is: take the acetonitrile / water solution of ruthenium-coordinated pyrrole monomer and lithium perchlorate as the electrolyte solution, the volume ratio of acetonitrile / water is 1:3, and the ruthenium-coordinated pyrrole monomer The molar concentration of lithium perchlorate is 0.1mol / L, and the molar concentration of lithium perchlorate is 0.1mol / L. A ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Mass specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com