A knee joint bone cement spacer mold

A spacer and bone cement technology, applied in knee joints, joint implants, joint implants, etc., can solve the problems of inconvenient removal and increase the difficulty of medical workers' work, and achieve convenient demoulding, convenient production, The effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-8 The application is described in further detail.

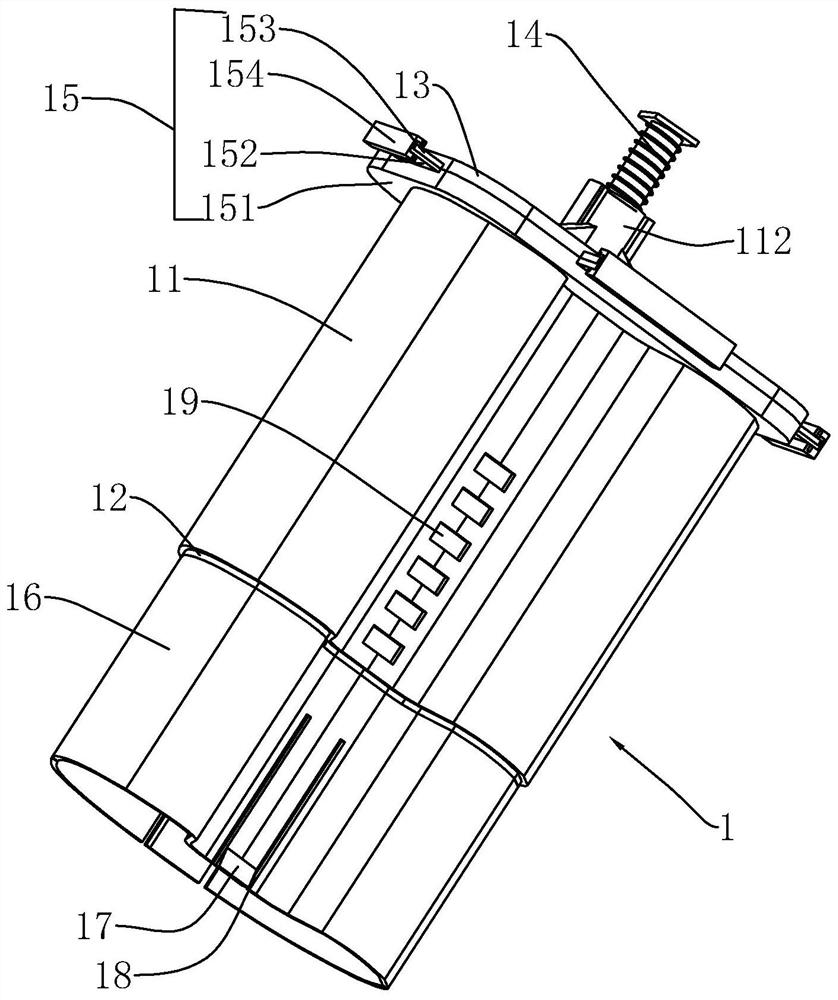

[0042] The embodiment of the present application discloses a knee joint bone cement spacer mold. refer to figure 1 , Figure 5 , a bone cement spacer mold of the knee joint, including a femoral spacer mold 2, a tibial spacer mold 1 and a gap measurement kit used in conjunction with the knee joint infection revision surgery. The spacer mold is obtained by heating and injection molding of polypropylene material, which has high heat resistance and chemical resistance, can be aseptically sterilized, and will not be damaged during the exothermic stage when the bone cement is solidified and shaped. This mold is a one-time use product, even if the mold is slightly deformed when the bone cement is heated, it will not affect it.

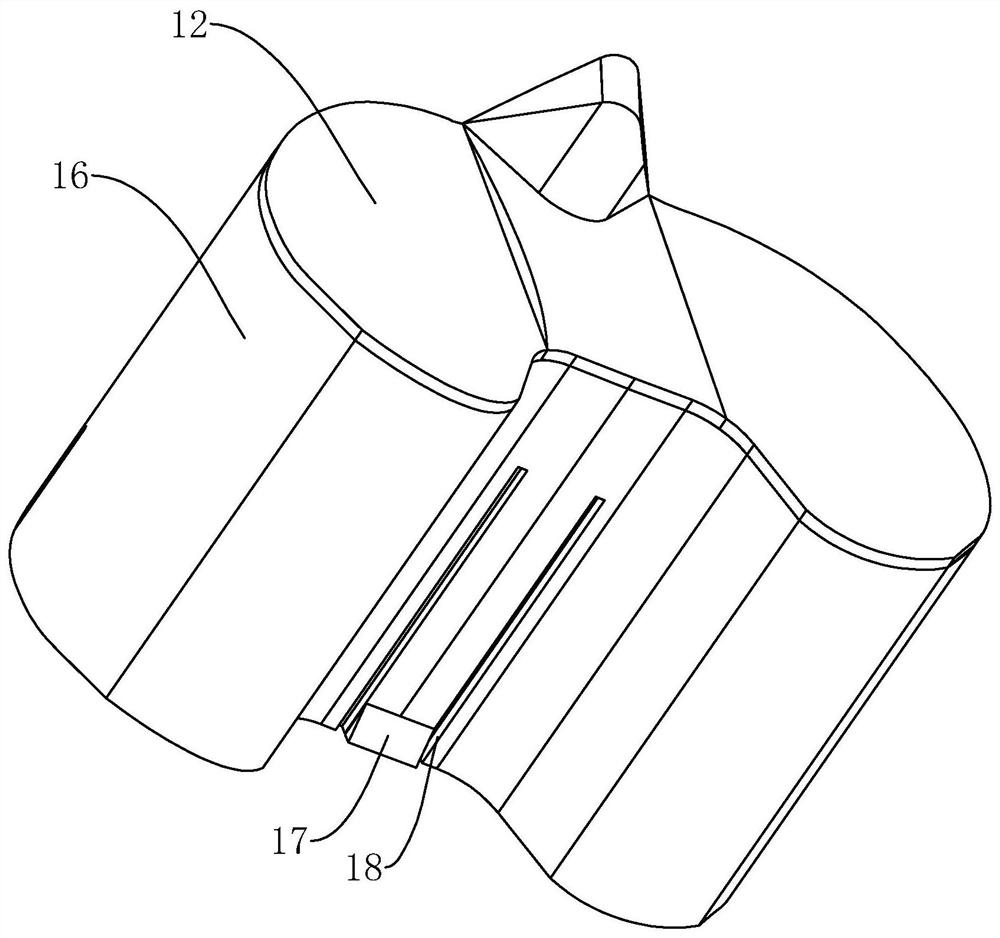

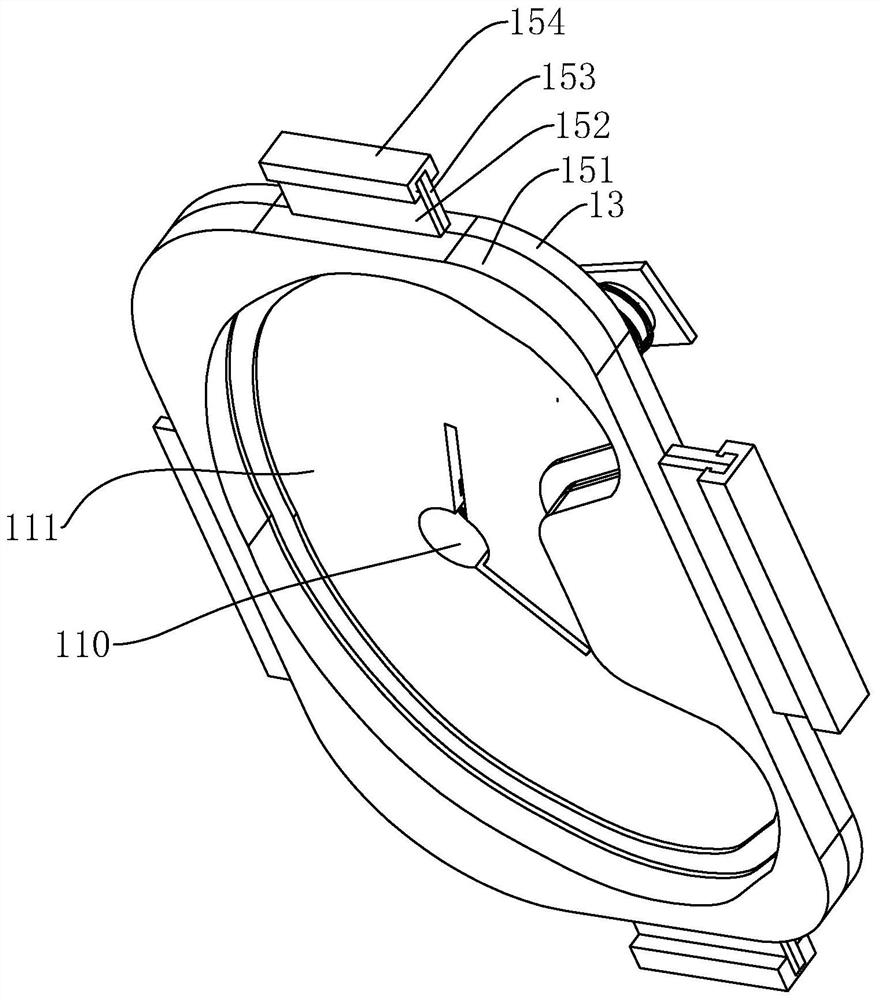

[0043] refer to figure 1 , figure 2The tibial spacer mold 1 includes a sleeve 11 , a shaping holder 12 , a shaping cover 13 , a tibial sprue 14 and a tibial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com