Chemical polymer material production equipment

A technology of polymer materials and production equipment, applied in the direction of feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of single sealing structure, inability to realize multiple seals, and inability to realize simultaneous sampling of different liquid levels, etc. problem, to achieve the effect of providing buffer time, improving mixing effect and improving sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

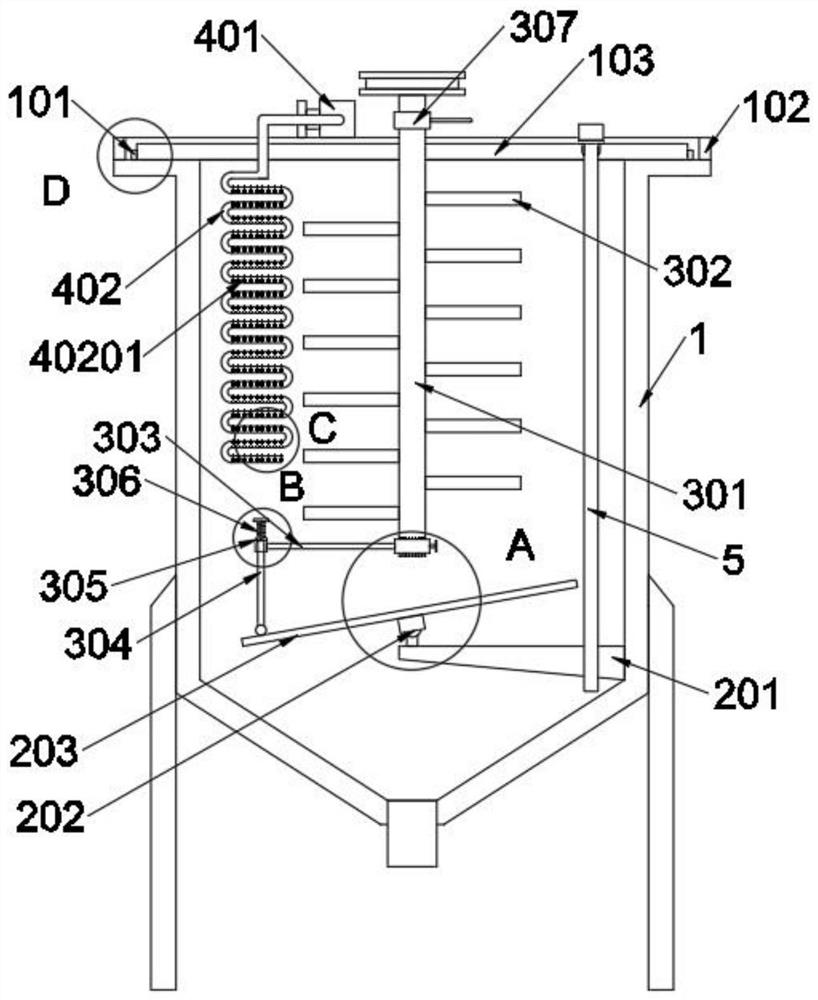

[0035] as attached figure 1 to attach Figure 8 Shown:

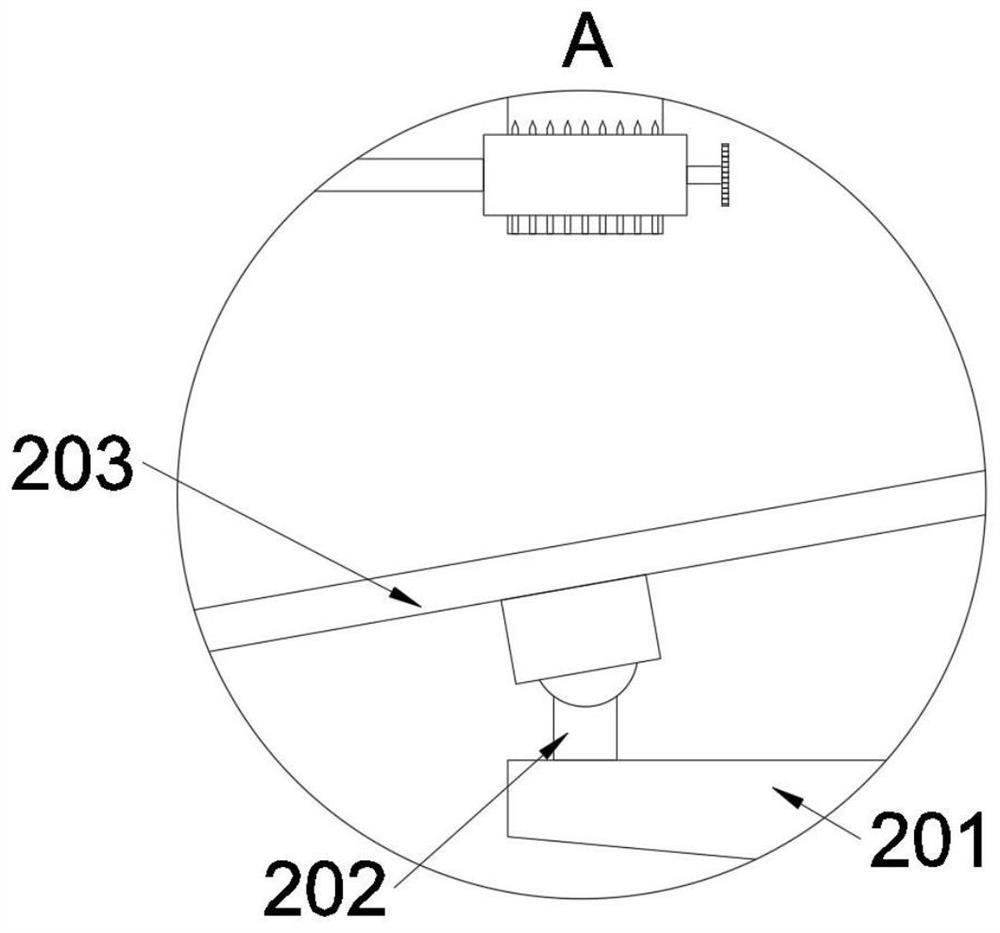

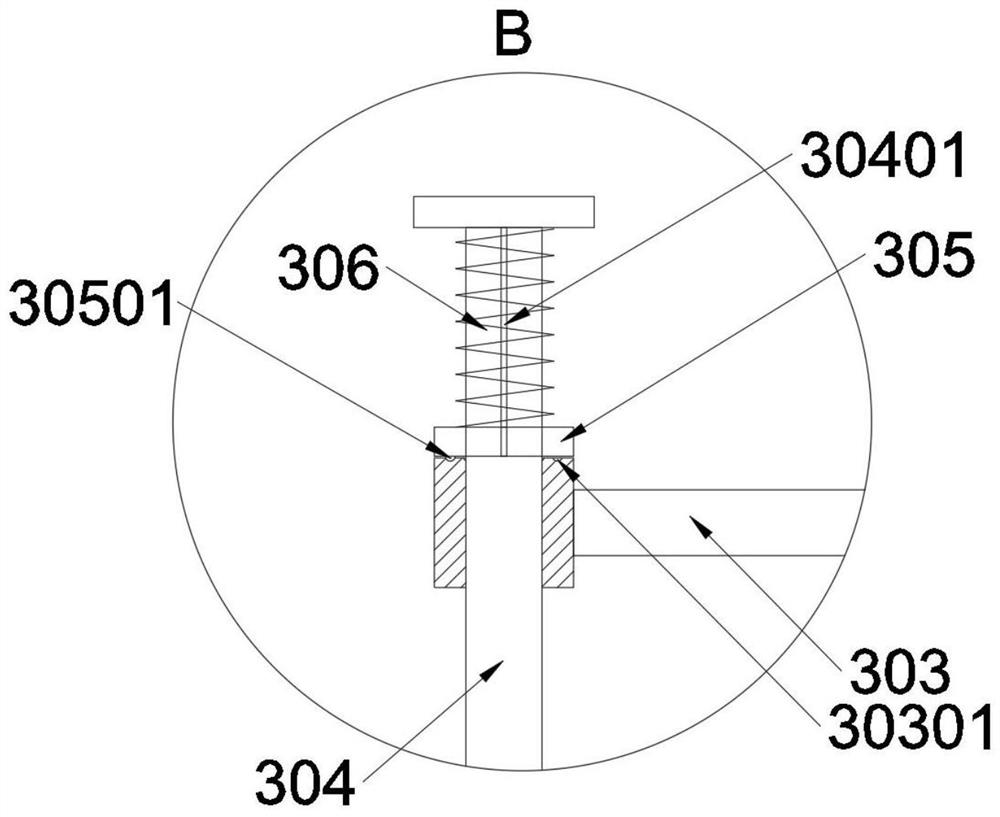

[0036] The invention provides a chemical polymer material production equipment, which comprises a barrel body 1; a first mixing structure 2 is installed in the barrel body 1, and a second mixing structure 3 is also rotatably connected to the barrel body 1; There is a gas mixing structure 4, and a sampling structure 5 is also installed on the barrel body 1; refer to as figure 1 , the second mixing structure 3 comprises a stirring shaft 301, a stirring tooth 302, an installation arm 303 and a toggle rod 304, the stirring shaft 301 is rotatably connected to the cover plate 102, and the stirring tooth 302 is welded on the stirring shaft 301; A mounting arm 303 is fixedly connected by bolts, and a toggle lever 304 is threaded on the mounting arm 303; the toggle lever 304 is in contact with the top surface of the mixing plate 203, and now the mixing plate 203 has an inclination angle of 20 degrees, and when When the stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com