A laser welding method for 7-series aluminum alloy plates with a thickness greater than 40mm

An aluminum alloy sheet and laser welding technology, applied in the field of aluminum alloy materials, can solve the problems of workpiece deformation, affecting popularization and application, and difficult process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

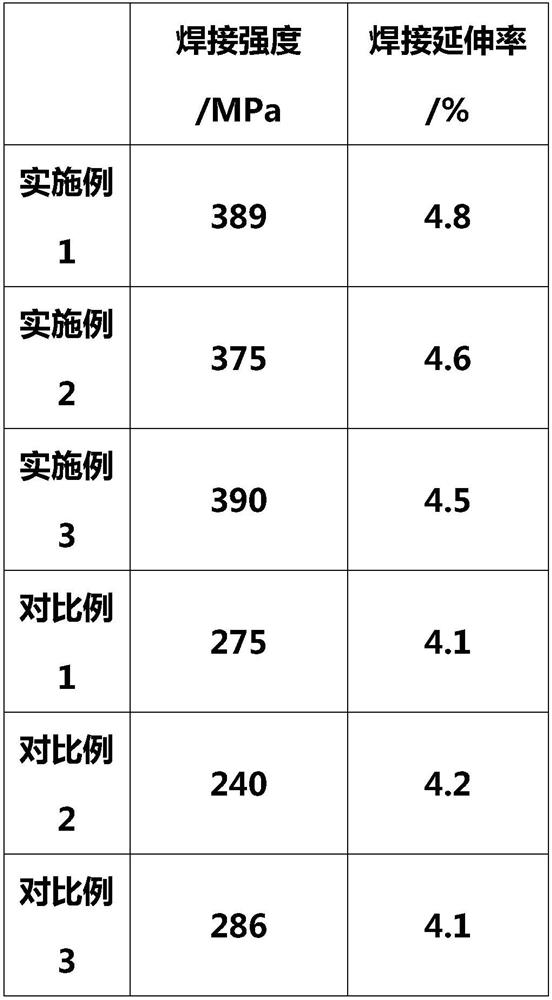

Examples

Embodiment 1

[0014] A laser welding method for 7-series aluminum alloy plates with a thickness greater than 40 mm, the laser welding method comprising: the main laser is a YAG laser, the auxiliary laser is a CO2 laser, and the two are placed in sequence along the welding direction, with the main laser in front and the auxiliary laser In the end, the power of the auxiliary laser is 50% of the power of the main laser, and the beam width of the auxiliary laser is 1.6 times that of the main laser beam. Welding is performed at a certain welding speed, and the protective atmosphere is He gas and Ar gas, with a ratio of 3.5:1.

[0015] The mass percentages of the components of the 7-series aluminum alloy sheet are as follows: Si: 0.5%, Cu: 0.2%, Zn: 5.7%, Mg: 1.7%, Zr: 0.1%, Fe: 0.3%, Ti: 0.25%, Mn: 0.6 %, W: 0.2%, other elements individually ≤0.05%, the sum of other elements ≤0.15%, and the balance is Al.

[0016] The laser power of the main laser is 3kW, the welding speed is 1m / min, the focal l...

Embodiment 2

[0018] A laser welding method for 7-series aluminum alloy plates with a thickness greater than 40 mm, the laser welding method comprising: the main laser is a YAG laser, the auxiliary laser is a CO2 laser, and the two are placed in sequence along the welding direction, with the main laser in front and the auxiliary laser In the end, the power of the auxiliary laser is 40% of the power of the main laser, and the beam width of the auxiliary laser is 1.8 times the beam width of the main laser. Welding is performed at a certain welding speed. The protective atmosphere is He gas and Ar gas, and the ratio is 3:1.

[0019] The laser power of the main laser is 3kW, the welding speed is 1m / min, the focal length of the laser beam is 200mm, and the defocus is +3mm--2mm.

Embodiment 3

[0021] The laser welding method includes: the main laser is a YAG laser, the auxiliary laser is a CO2 laser, the two are placed in sequence along the welding direction, the main laser is in front, the auxiliary laser is behind, the power of the auxiliary laser is 60% of the main laser power, and the auxiliary laser beam The width is 1.3 times the beam width of the main laser, and welding is performed at a certain welding speed. The protective atmosphere is He gas and Ar gas, and the ratio is 4:1.

[0022] The laser power of the main laser is 3kW, the welding speed is 1m / min, the focal length of the laser beam is 200mm, and the defocus is +3mm--2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Defocus amount | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap