Column welding system

A welding system and column technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding efficiency of column and unsmooth welding operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

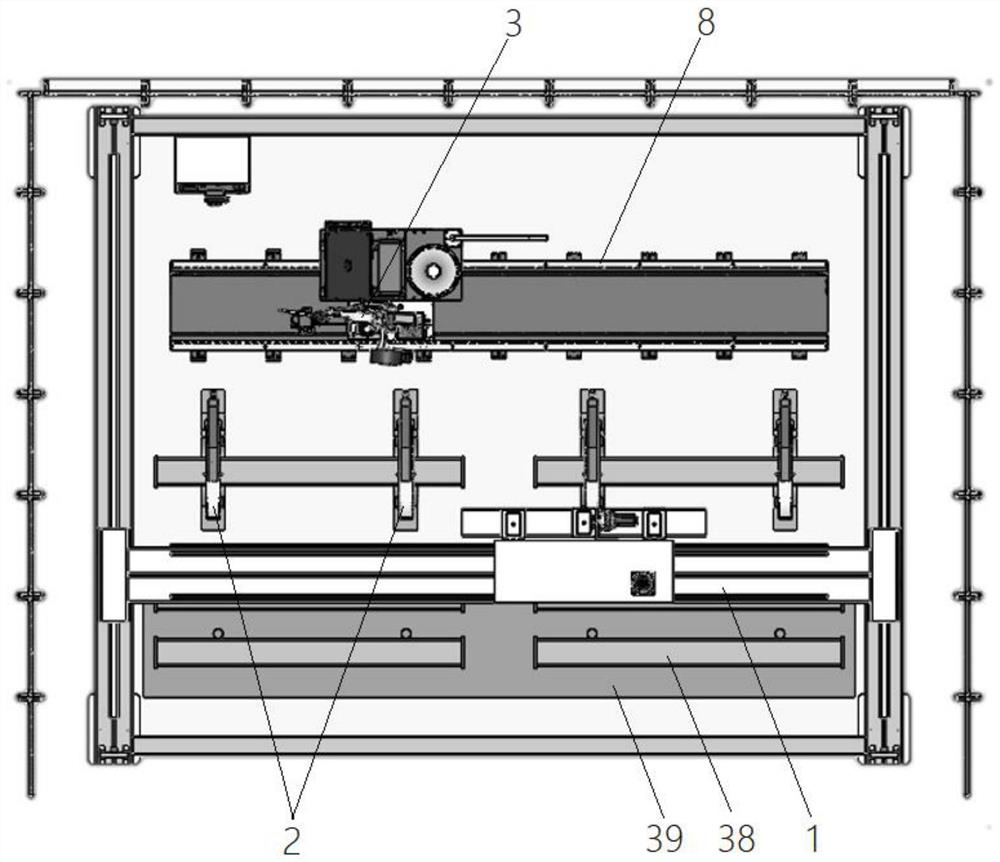

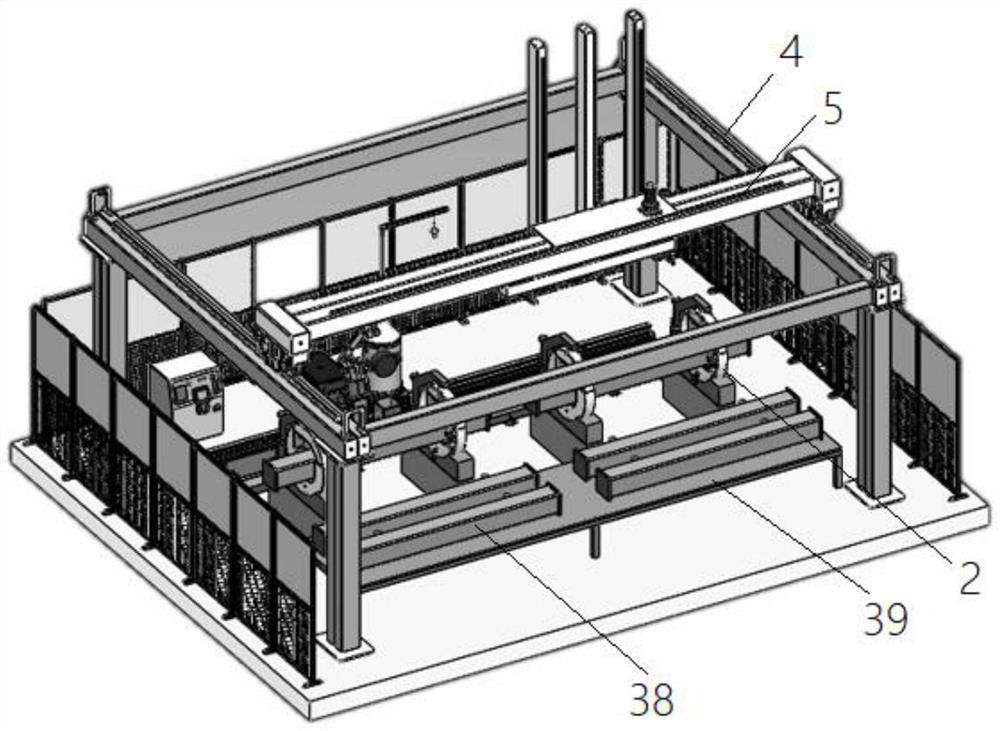

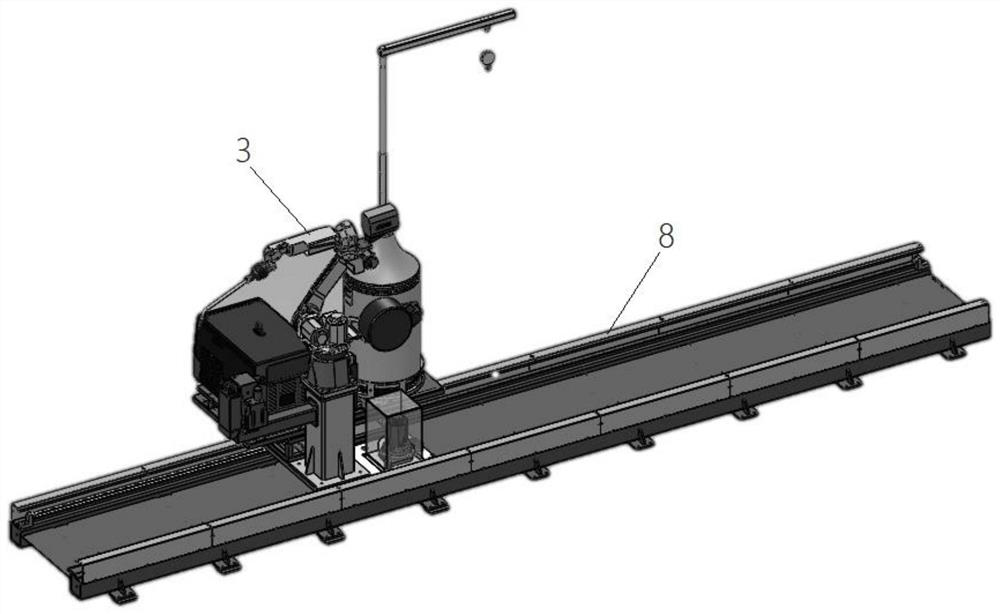

[0030] Such as Figure 1 to Figure 6 As shown, a column welding system includes a truss mechanism 1 , a positioner 2 and a welding robot 3 . Such as Figure 6 As shown, the truss mechanism 1 includes a three-axis slide table and a fixture installed on the Z-axis slide table 5 of the three-axis slide table. The three-axis slide table and the fixture can cooperate to move the workpiece to the positioner; specifically, the present The fixture of the system includes a fixed frame 36 installed on the Z-axis slide table 5, and at least two electromagnets 37 installed on the fixed frame 36. The workpieces involved in this system are also made of magnetically absorbable materials, and the electromagnets 37 are energized Finally, the workpiece can be absorbed, and the structure of the fixture is simple and practical.

[0031] Such as figure 1 and figure 2 As shown, the welding system also includes a buffer station 39, on which a plurality of workpieces 38 can be placed, the buffer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com