Efficient chopping mechanism of waste plastic woven bag environment-friendly recycling device

A waste plastic and recycling device technology, applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., to achieve the effect of improving shredding efficiency, improving effect, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

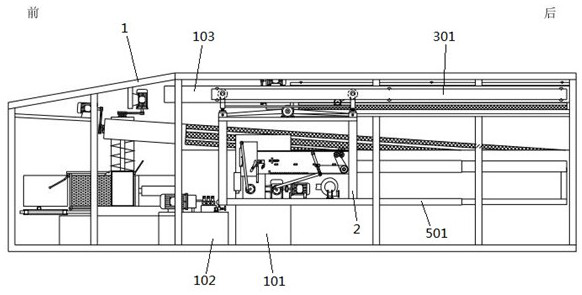

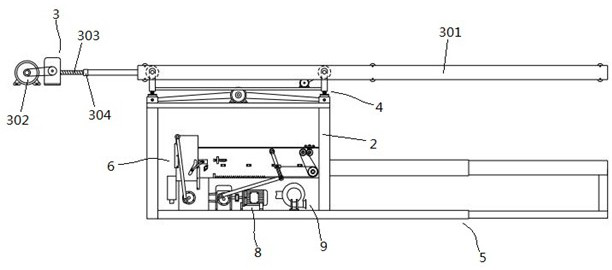

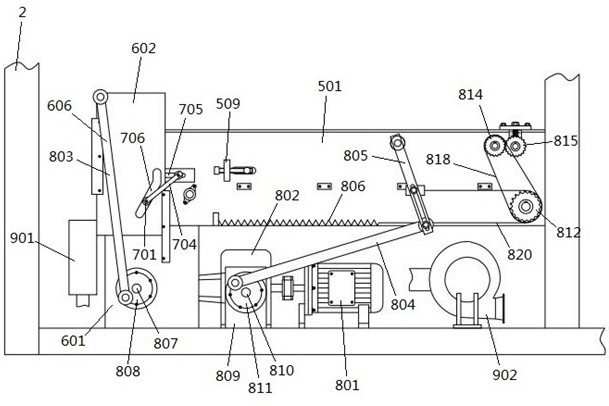

[0033] Example 1: as Figures 1 to 8 As shown, an efficient shredding mechanism of an environmentally friendly recycling device for waste plastic woven bags includes a frame 1, a suspension 2, a pushing component 3, a lifting component 4, a bag feeding component 5, a shredding component 6, a pushing component 7, The transmission assembly 8 and the material conveying assembly 9; the frame 1 is placed on the ground or in the carriage of the tractor, and the frame 1 is connected with an electric control cabinet 101 and a hydraulic station 102; the lifting assembly 4 is connected with the suspension 2, the lift assembly 4 is slidably connected to the push assembly 3, the push assembly 3 pushes the suspension 2 to extend to the outside of the frame 1, the bag feeding assembly 5 is connected to the suspension 2, the shredding assembly 6 and the pushing assembly 7 are connected to the feeder. At one end of the bag assembly 5 , the transmission assembly 8 drives the bag feeding assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com