Biomass new energy device

A new energy and biomass technology, applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of low efficiency and long time, and achieve the effect of improving the cutting efficiency and cutting uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

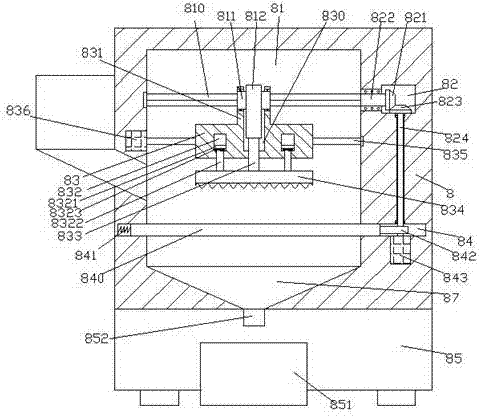

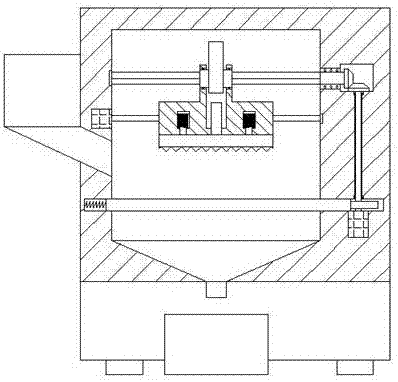

[0018] Such as Figure 1-Figure 4 As shown, a biomass new energy device of the present invention includes a main body 8, a first cavity 81 is arranged in the main body 8, and a cone cavity extending downward is connected to the bottom of the first cavity 81. 87, the first cavity 81 is provided with a movable frame 83 that is smoothly connected between the front and rear end surfaces and the front and rear inner walls of the first cavity 81, and the movable frame 83 is provided with a helical thread that is connected and extended left and right. Rod 835, the top surface of the movable frame 83 is provided with a slot 830, and the left and right sides of the top of the slot 830 are fixed with support frames 831 extending upwards, and the support frames 831 on the left and right sides are rotated A locking sleeve 811 is mated and connected, and a first deflection wheel 812 is fixedly arranged on the outer surface of the locking sleeve 811, and a locking shaft extending to the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com