Bamboo shoots shredding machine

A shredding machine and bamboo shoot technology, which is applied in metal processing and other fields, can solve the problems of different sizes of bamboo shoots, frequent safety accidents, and low shredding efficiency, and achieve the effect of uniform size, low safety accidents, and high shredding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

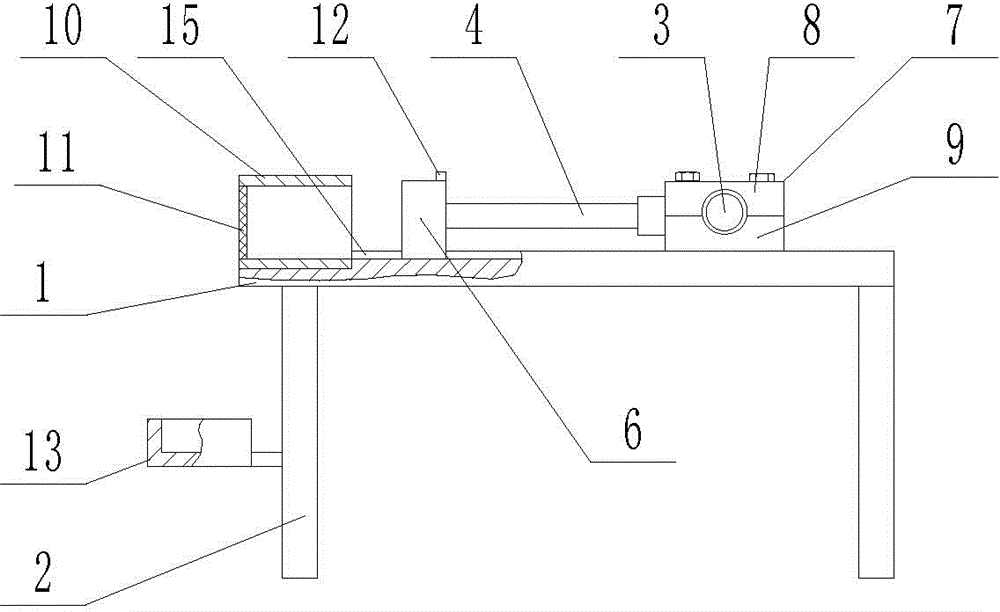

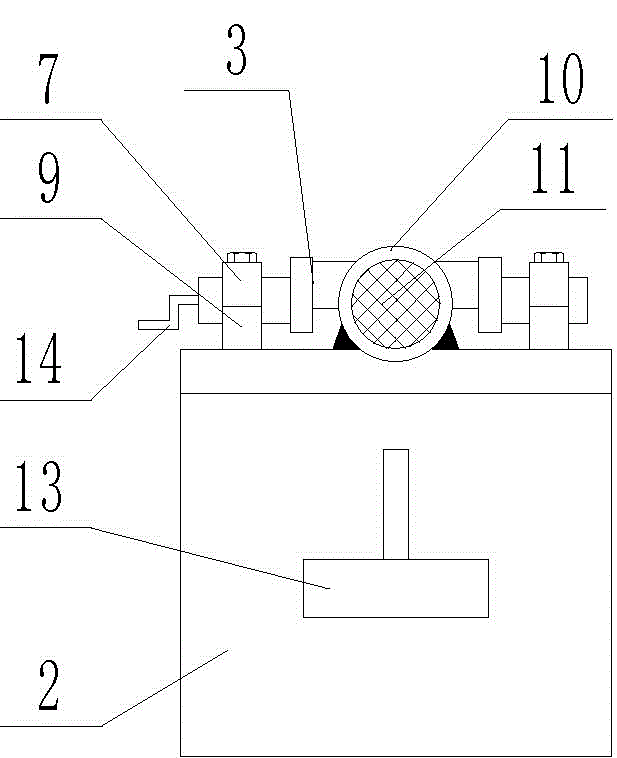

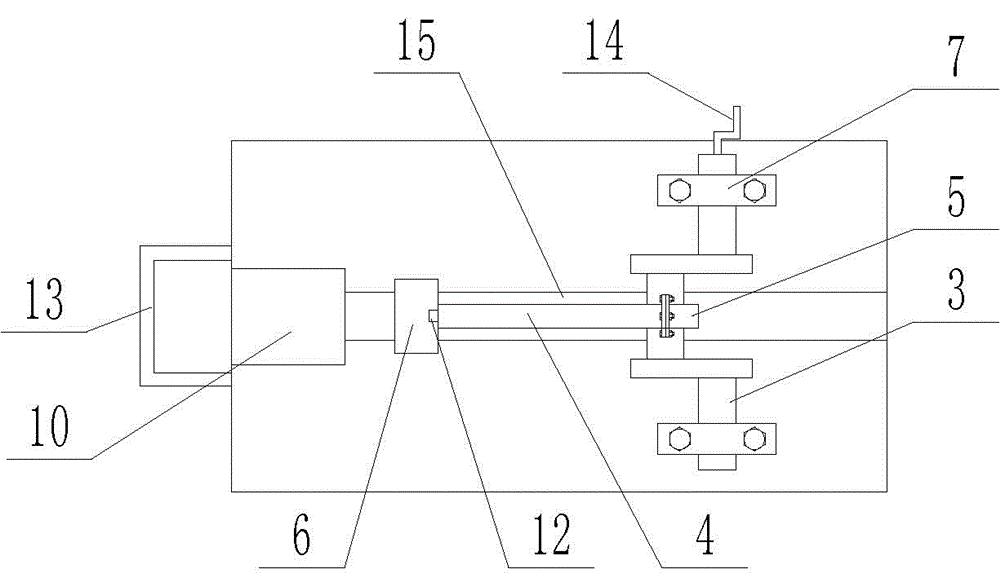

[0018] The reference signs in the drawings of the description include: support plate-1, vertical plate-2, crankshaft-3, connecting rod-4, connecting rod cover-5, push block-6, support seat-7, upper support seat-8 , Lower support seat-9, sleeve-10, wire cutting net-11, positioning block-12, material frame-13, handle-14, groove-15.

[0019] The embodiment is basically as attached figure 1 , figure 2 , image 3 Shown: bamboo shoot shredding machine is made up of a support plate 1, two vertical plates 2, a crankshaft 3, a connecting rod 4, connecting rod cover 5, push block 6 and material frame 13; The bottom surface of the plate 1 is fixedly connected; the support plate 1 is provided with two support seats 7, and the support seat 7 is a split support seat 7, which is composed of an upper support seat 8 and a lower support seat 9, and the upper support seat 8 and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com