Cutter assembly

A chopper and component technology, applied in cutting equipment, agricultural machinery and implements, applications, etc., can solve the problems of low distribution efficiency of the crushing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

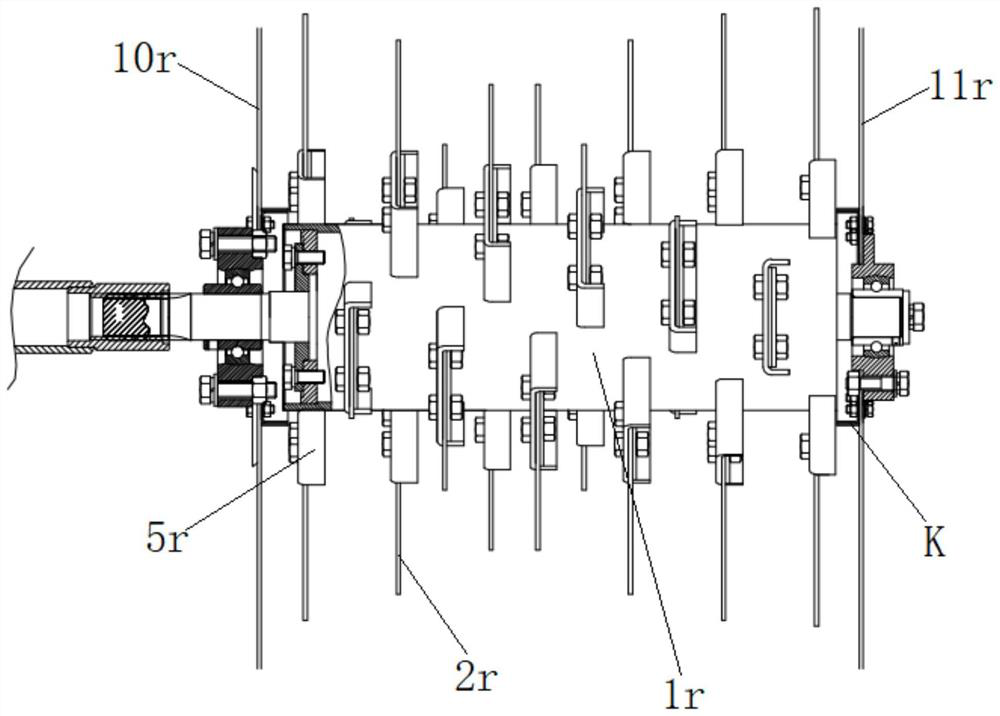

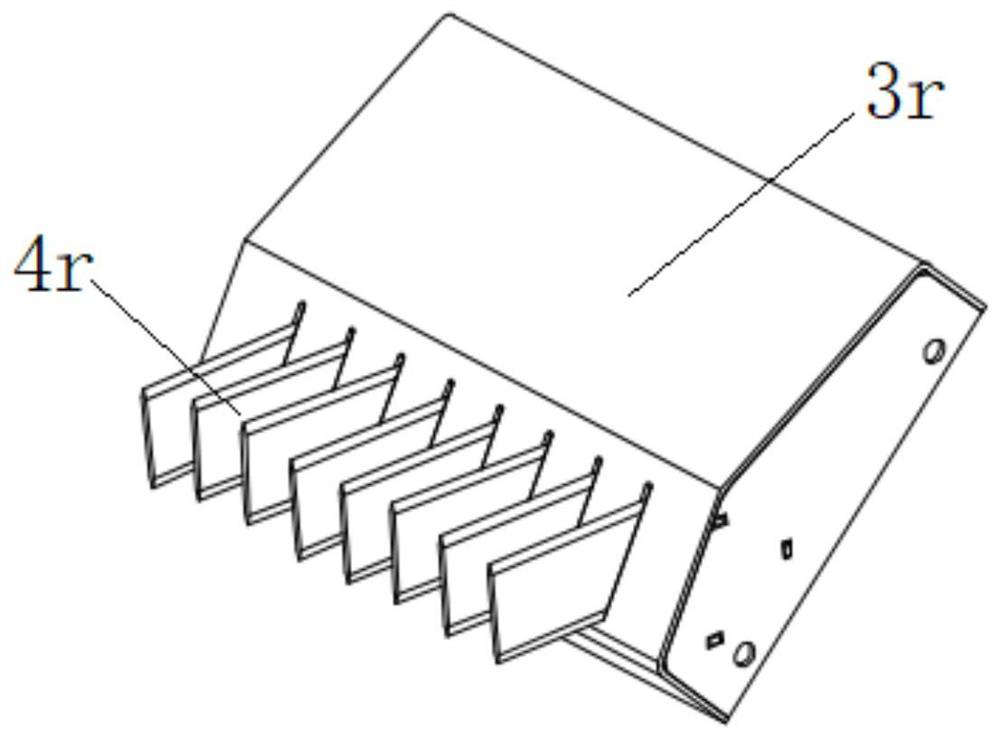

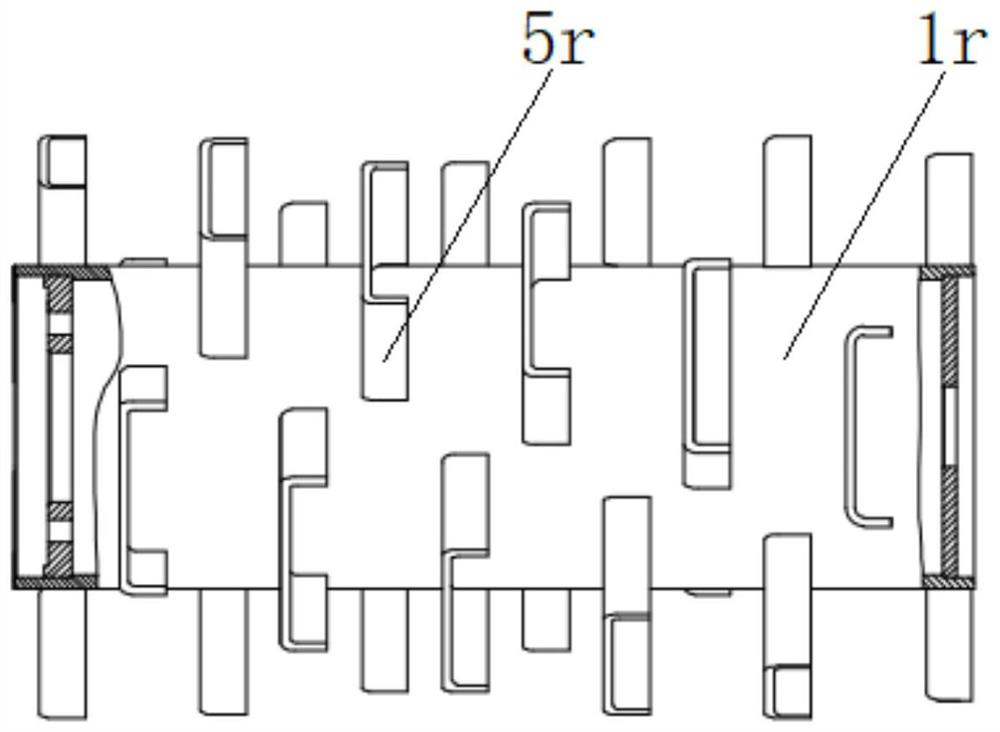

[0051] This embodiment provides a chopper assembly, such as figure 1 and Figure 8 As shown, it includes the grass discharge channel and the grass inlet (not shown) and the grass discharge port 10p located at the two ends of the grass discharge channel, and the two ends of the movable knife roller 1r are rotatably fixed on the left side wall 10r and the grass discharge channel. The right side wall 11r, in order to clearly display other structures, the left side wall 10r and the right side wall 11r are in figure 1 are only partially shown. The moving knife roller 1r is a cylindrical roller. A plurality of moving blades 2r are arranged in a helical shape and are detachably mounted on the moving knife roller 1r, and any moving blade 2r is parallel to the cross section of the moving knife roller 1r.

[0052] like image 3As shown, a plurality of movable knife seats 5r are welded and fixed on the movable knife roller 1r, and the movable blades 2r correspond to each other and ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com