Pneumatic fastening tool for shield conical surface arc scraping plate

A conical surface and circular arc technology, applied in the field of pneumatic fastening tooling, can solve the problems of easy inward collapse and difficult fixation of shield circular arc scrapers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

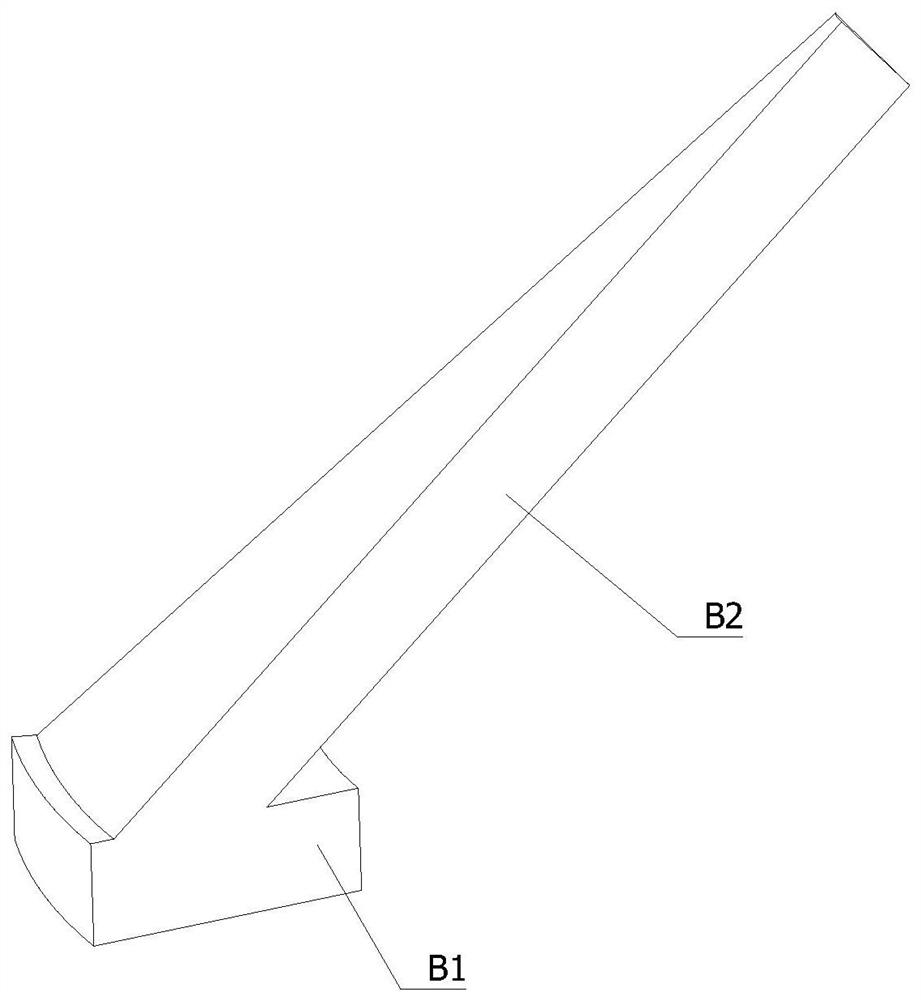

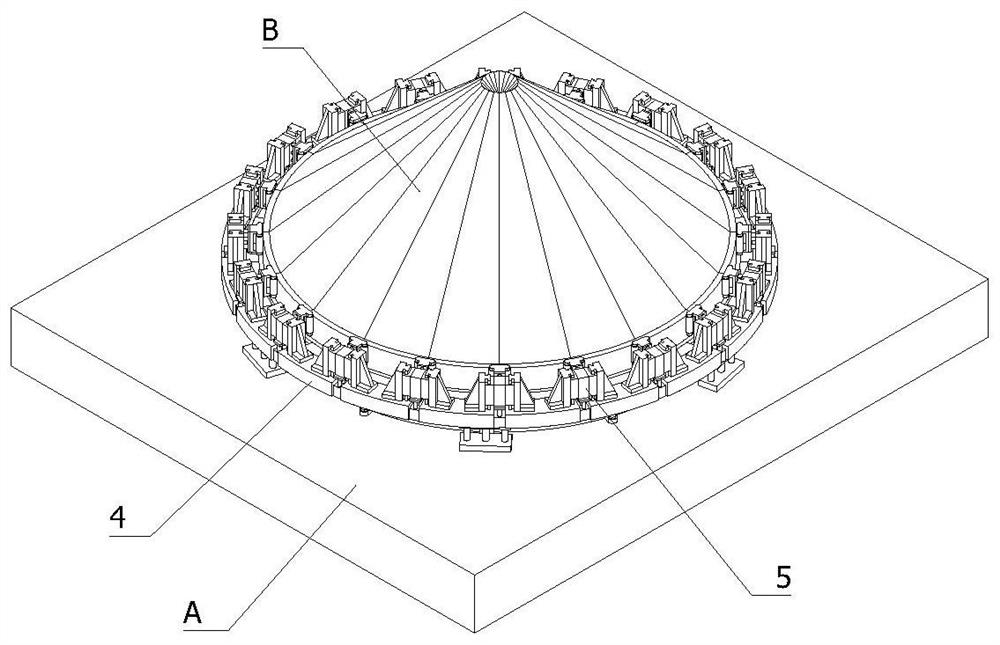

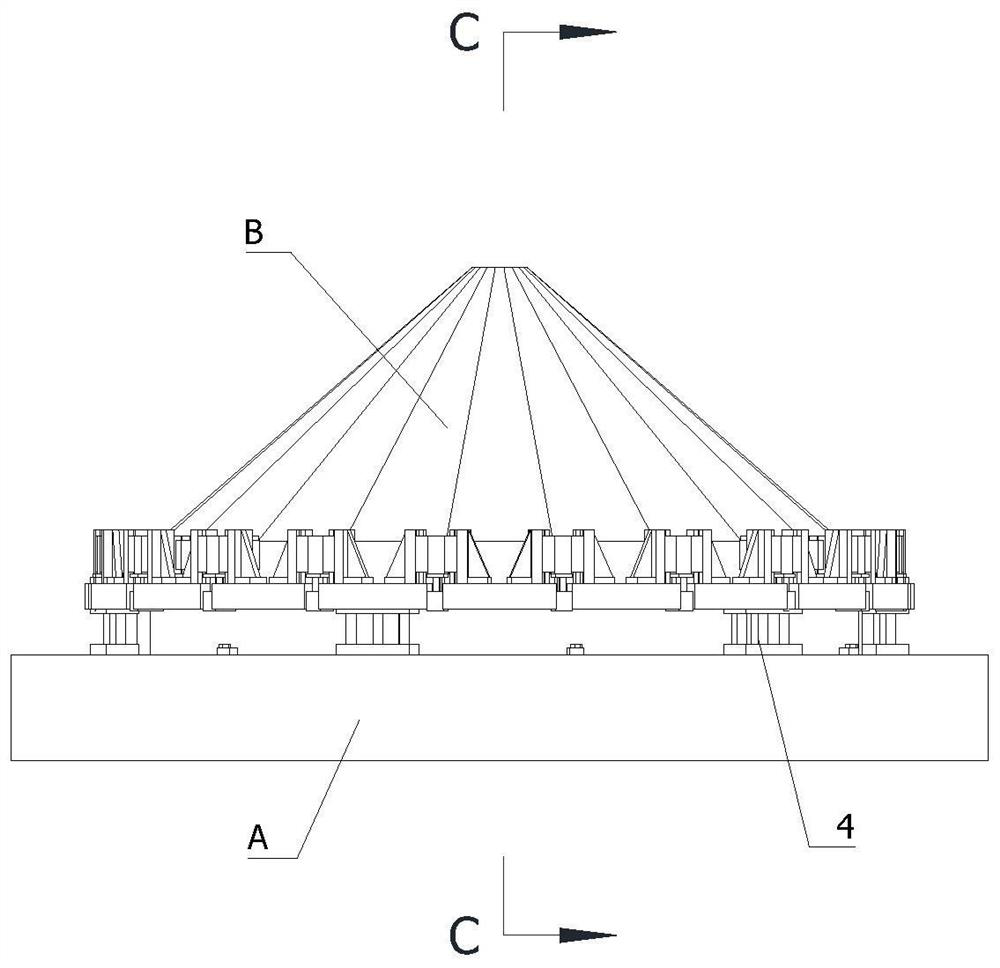

[0041] refer to Figure 4 As shown in the figure, a pneumatic fastening tool for shield conical arc scrapers is used to fix a plurality of workpieces B in a ring shape into cones on the top of workbench A, and the workpieces B include fan-shaped panels B1 and arc-shaped panel B2, the pneumatic fastening tool includes: bearing column 1, fixed horizontally on the top of the bearing column 1, the diameter of the bearing column 1 is larger than the maximum diameter of the cone; limit column 2, coaxially arranged At the top of the bearing column 1, the radius of the limiting column 2 is smaller than the radius of the inner arc of the cone fan-shaped panel B1, and the height of the limiting column 2 is smaller tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com