Internal rigid structure of soft mechanical arm and pneumatic mechanical arm type soft robot

A technology of rigid structure and soft machinery, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as not easy to solid, small rigidity, position and angle offset, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings.

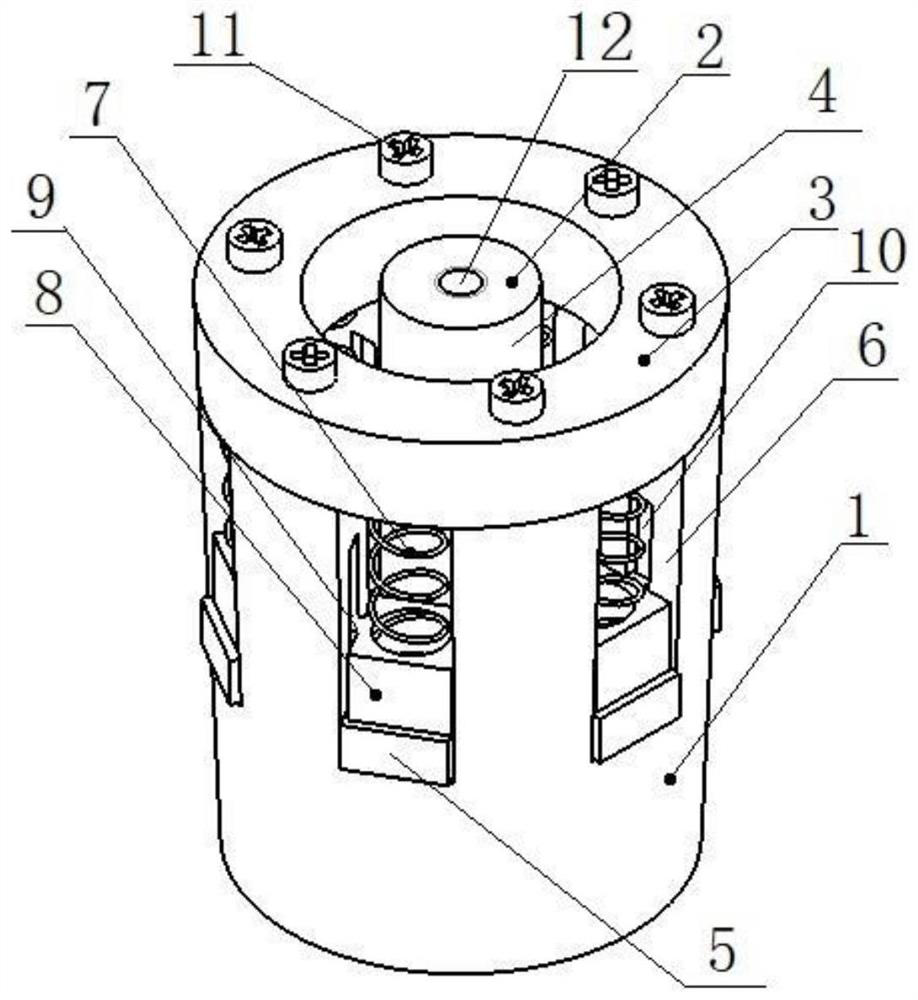

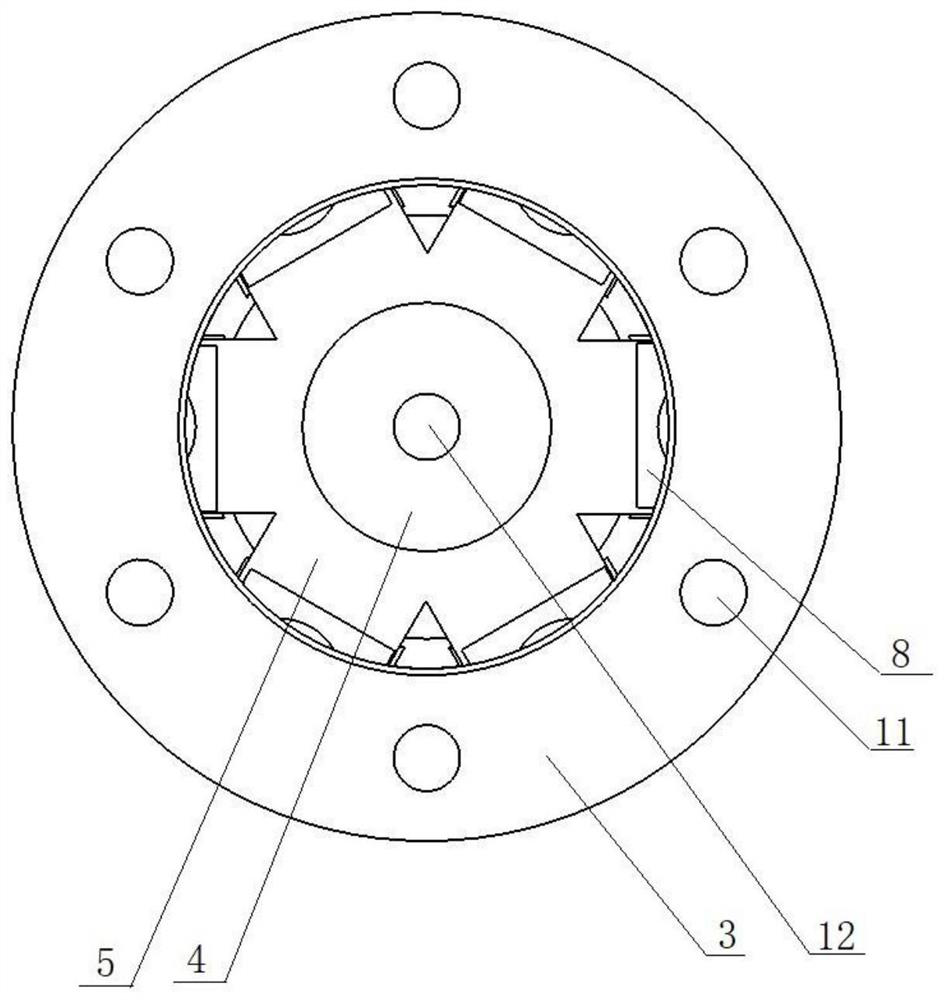

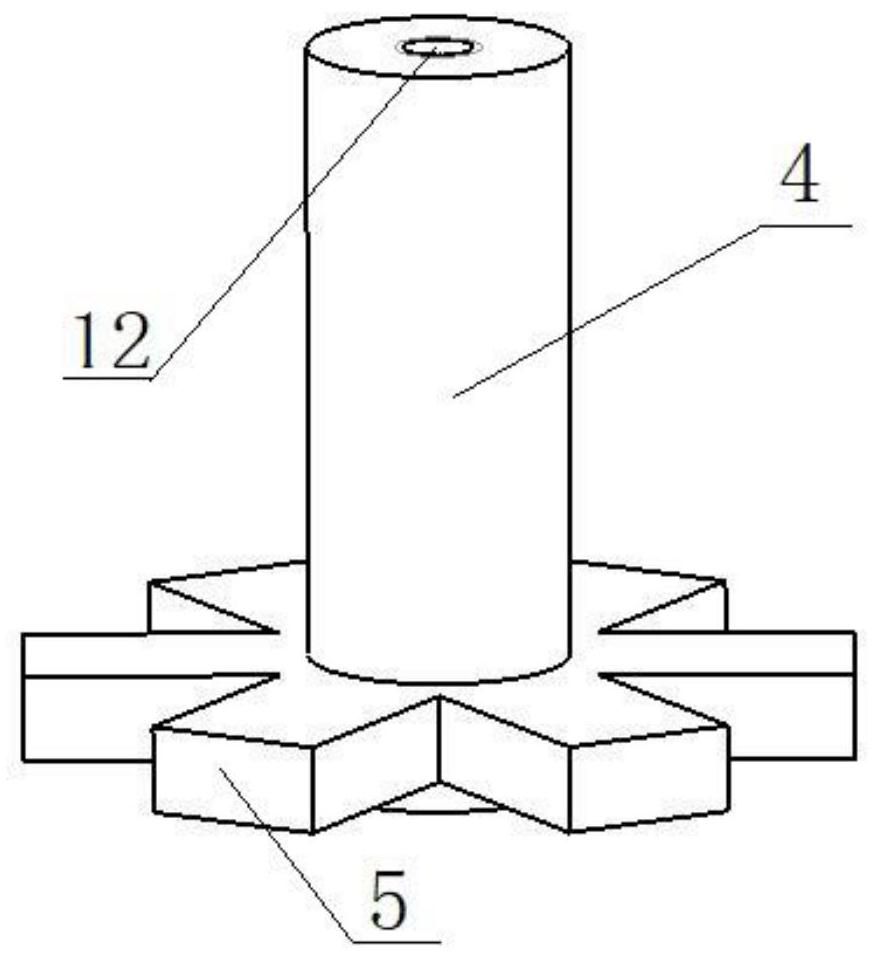

[0030] Such as figure 1 and figure 2 As shown, a kind of internal rigid structure of the soft mechanical arm includes a sleeve 1, a steering frame 2 arranged inside the sleeve and a sleeve cover 3 of a hollow ring structure, and the steering frame includes a rotating shaft 4, such as image 3 As shown, the end of the rotating shaft extending into the sleeve is vertically provided with 6 sliding parts 5 of flat rectangular parallelepiped structure, the sliding parts are distributed radially around the rotating shaft, and the middle part of the end of the rotating shaft far away from the sleeve is provided with a threaded groove 12. The lower part of the barrel is provided with a mounting hole (not shown in the figure) that matches the shape of the threaded slot hole, and the rotating shaft is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com