Semi-automatic production process applied to ceramic sculpture

A semi-automatic, production process technology, applied in the process of producing decorative surface effects, ceramic molding machines, decorative arts, etc., can solve the problems of high cost and low work efficiency, and achieve low cost, good positioning, and stable finished products. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

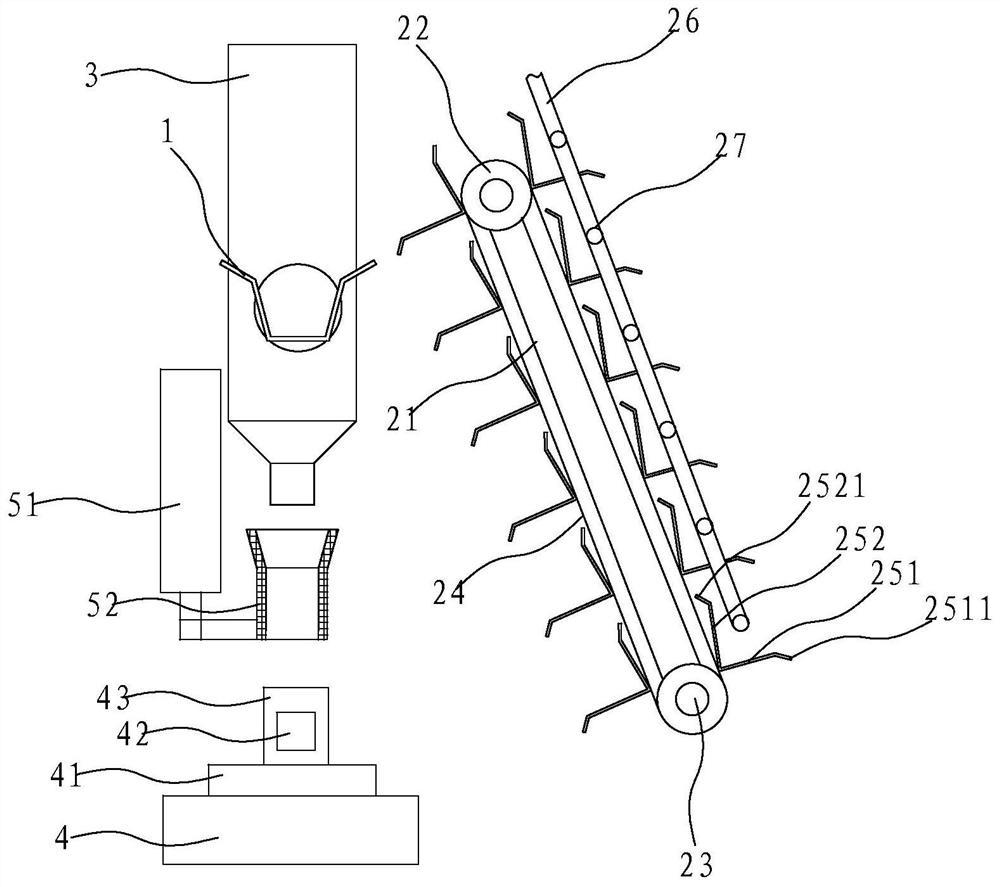

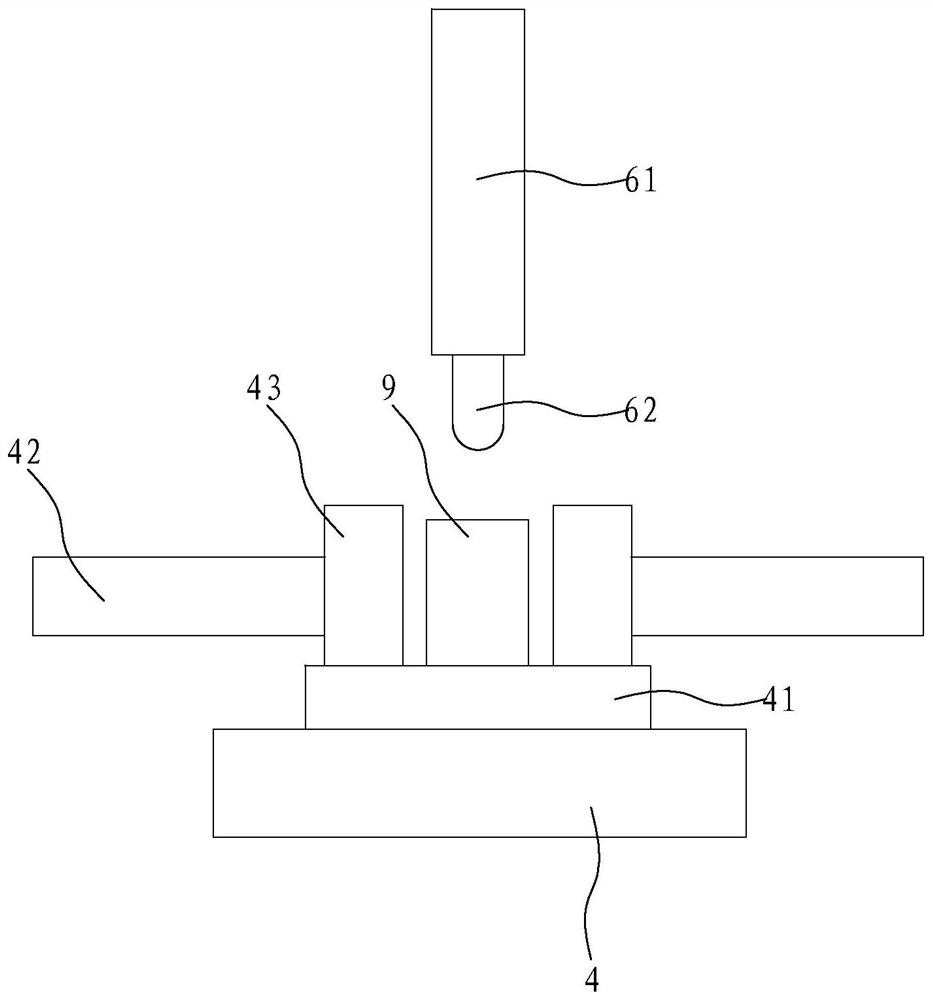

[0023] refer to Figure 1 to Figure 3 , the present embodiment provides a semi-automatic production process for ceramic engraving, comprising the following steps:

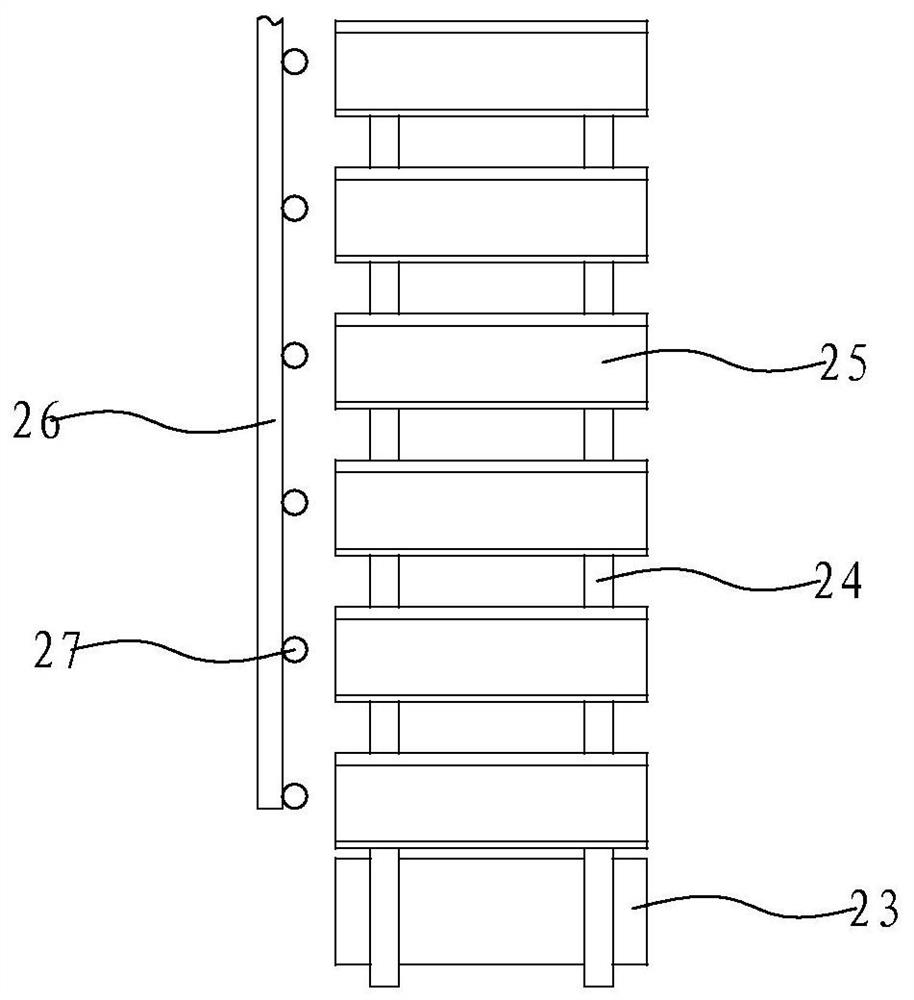

[0024] In the first step, the raw material is sent to the feeding platform 1 through the lifting mechanism, and the raw material is sent into the extrusion device through the feeding platform pressure 1. The lifting mechanism includes a lifting bracket 21, a driving roller 22, a passive roller 23, a shoe-wrapping driving roller 22 and a The chain 24 at the two ends of the passive roller 23, the plurality of object racks 25 located on the chain 24, each object rack 25 includes an object loading plate 251, a limiting plate 252, and the described object loading plate 251 and the limiting plate 252 are integrally formed. The included angle between the object loading plate 251 and the limitin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com