Automatic wrap angle processing equipment

A processing equipment and corner wrapping technology, which is applied in the field of automatic corner wrapping processing equipment, can solve the problems of inconvenient wrapping corner gluing processing, slow processing process, easy damage, etc., and achieves simple and convenient installation process, improved efficiency, and simple operation. convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

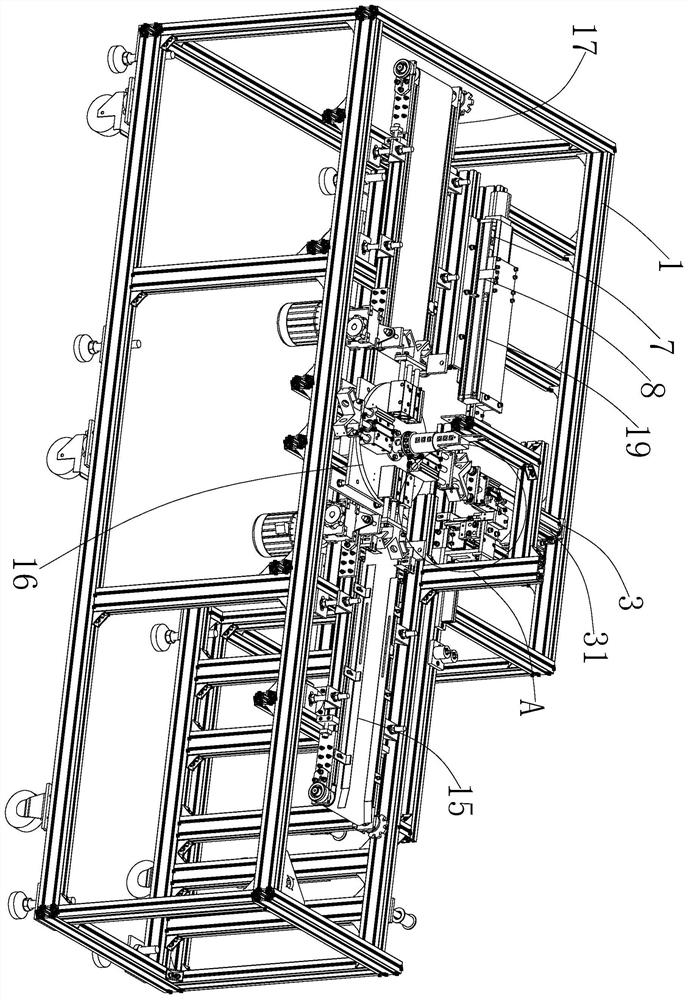

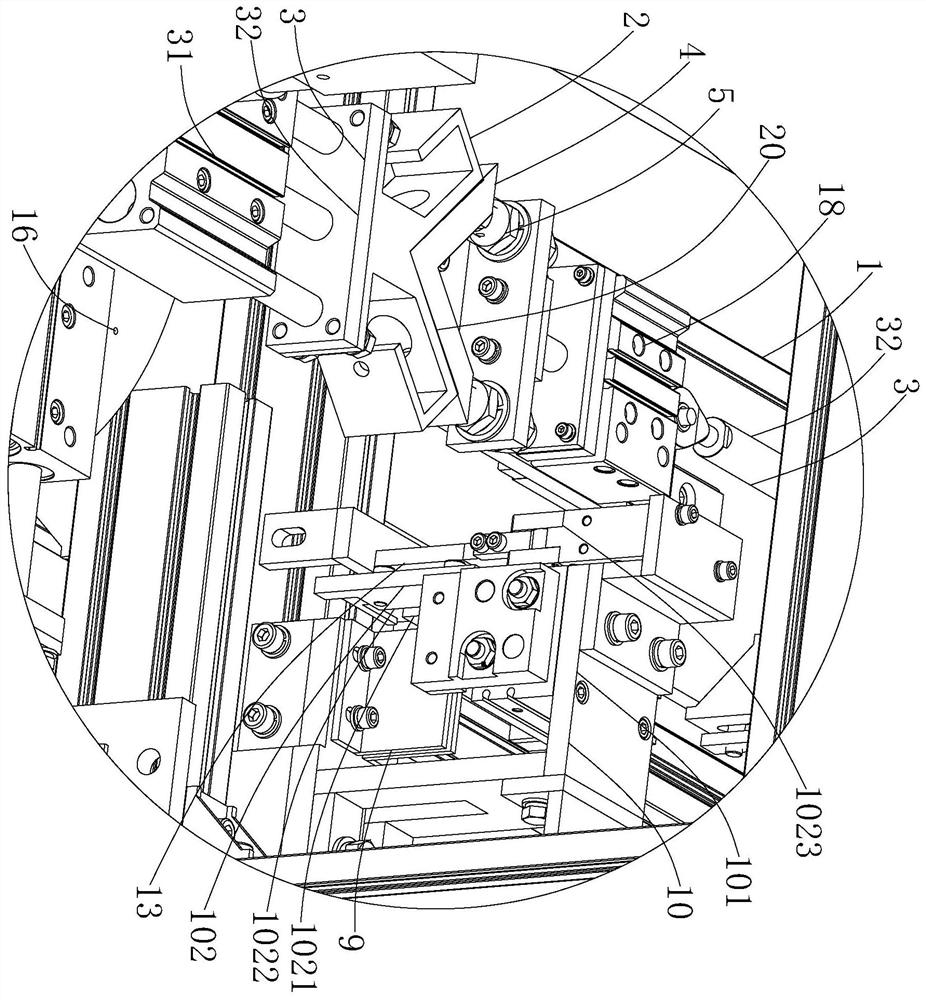

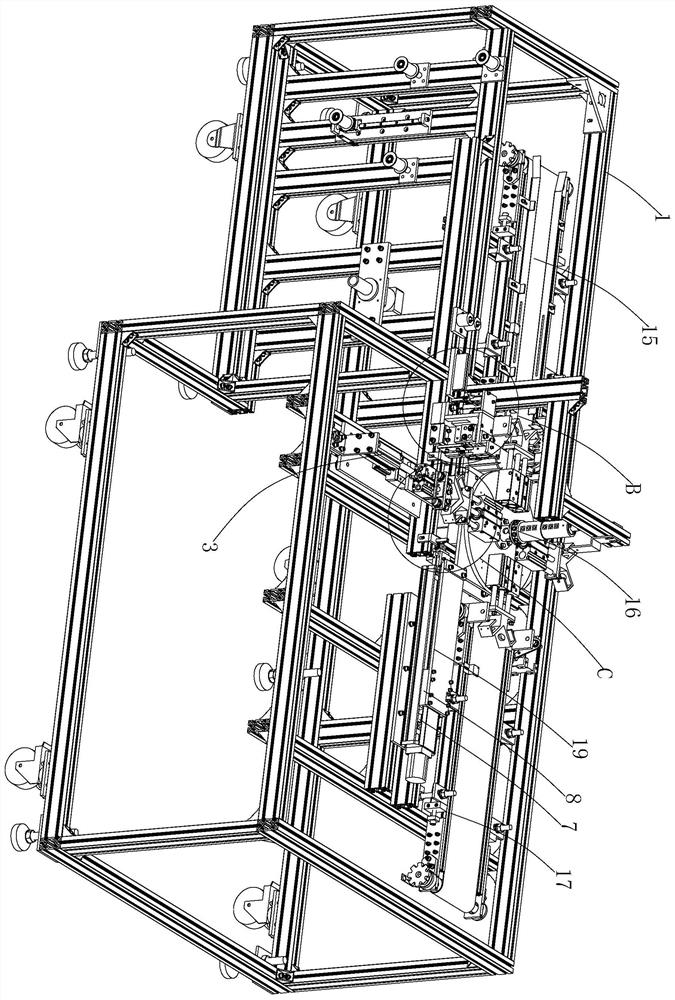

[0035] Embodiment: a kind of automatic wrap angle processing equipment, as Figure 1 to Figure 6 As shown, it includes a corner positioning seat 2 for clamping and positioning of plastic corners, a first linear drive mechanism 3, and a heating head assembly 5 that can hot-melt and fix the adhesive tape on the plastic corners. The seat 2 is provided with a first opening 20 through which the heating head assembly 5 can pass. The first linear drive mechanism 3 includes a first fixed end 31 that is stationary relative to the corner positioning seat 2, and can approach or move toward the first opening 20. away from the first movable end 32, the heating head assembly 5 is arranged on the first movable end 32

[0036] This scheme utilizes the hot-melt plasticity of the adhesive tape and the corner of the plastic, and through the heating effect of the heating head assembly 5, the adhesive tape and the corner of the plastic are melted and cooled to form a whole, so that the adhesive ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com