Packaging machine suitable for inner and outer separation of packaging bags

A packaging machine and packaging bag technology, applied in the field of automatic packaging of packaging bags, can solve the problems that packaging bags cannot be automated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

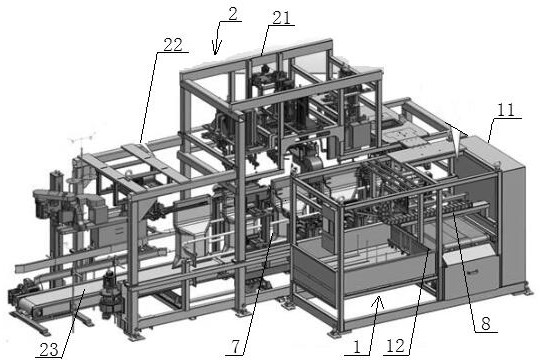

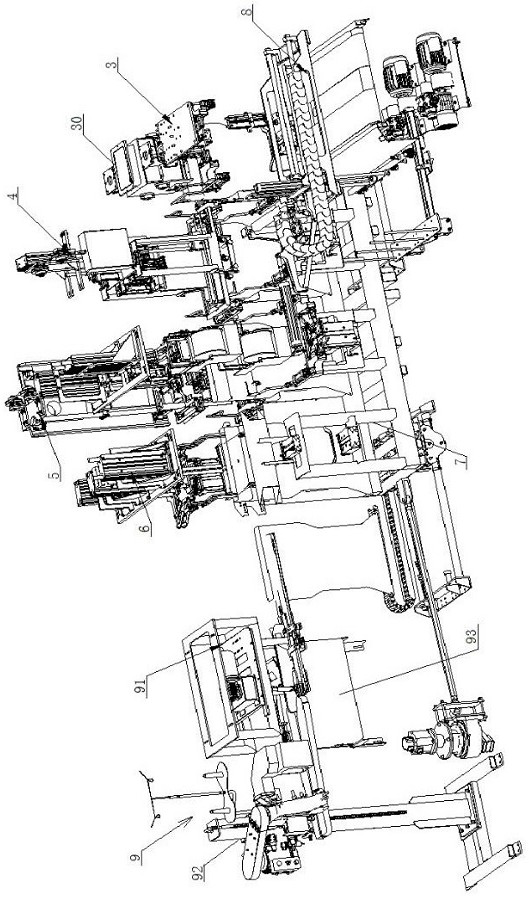

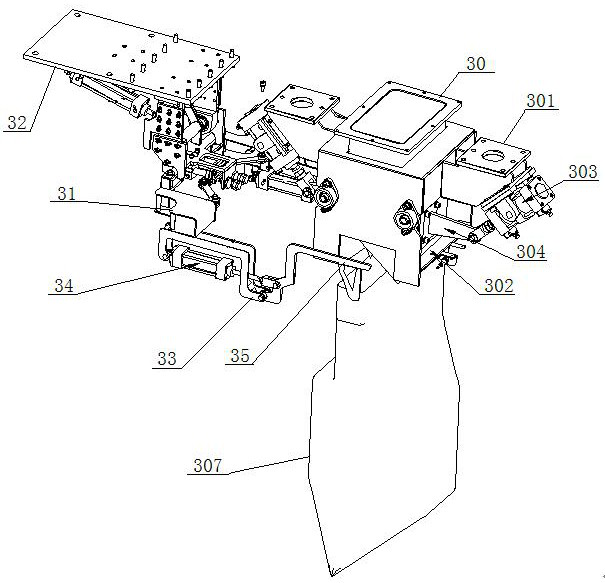

[0063] Such as Figures 1 to 12 as shown,

[0064] 01. A packaging machine adapted to separate the inside and outside of the packaging bag, including a bag storage unit 1 and a host unit 2. The bag storage unit 1 includes a distribution box 11, a bag storage rack 12 and a bag picking mechanism 8 , the host unit 2 includes a main upper frame 21, an auxiliary upper frame 22 and a chassis 23,

[0065] The bag-taking mechanism 13 is arranged on one side of the main upper frame 21, and is perpendicular to the main upper frame 21, the distribution box 11 is arranged on the right side of the bag-taking mechanism 8, and the bag storehouse frame 12 is arranged on The left side of the bag taking mechanism 8; the auxiliary upper frame 22 is arranged on the left side of the main upper frame 21, and is parallel to the main upper frame 21; the chassis 23 is arranged under the main upper frame 21 and the auxiliary upper frame 22 , and pass through the main upper frame 21 and the auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com