Elevator traction wheel state monitoring and early warning system and method based on algorithm model

A technology of monitoring and early warning and algorithmic models, applied in elevators, transportation and packaging, etc., can solve the problems of traction sheave wear, deflection, and accurate detection of internal cracks and cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

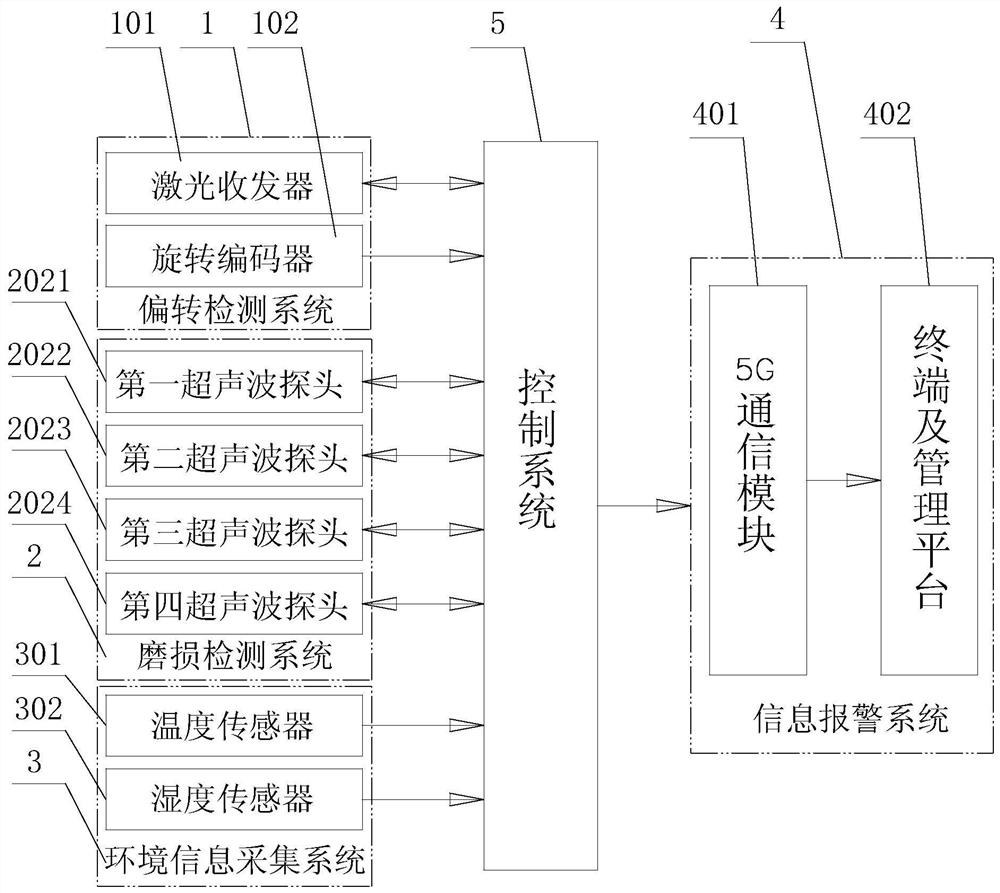

[0071] A state monitoring and early warning system for elevator traction sheaves based on an algorithm model, including a deflection detection system 1, a wear detection system 2, an environmental information collection system 3, an information alarm system 4, and a control system 5, wherein:

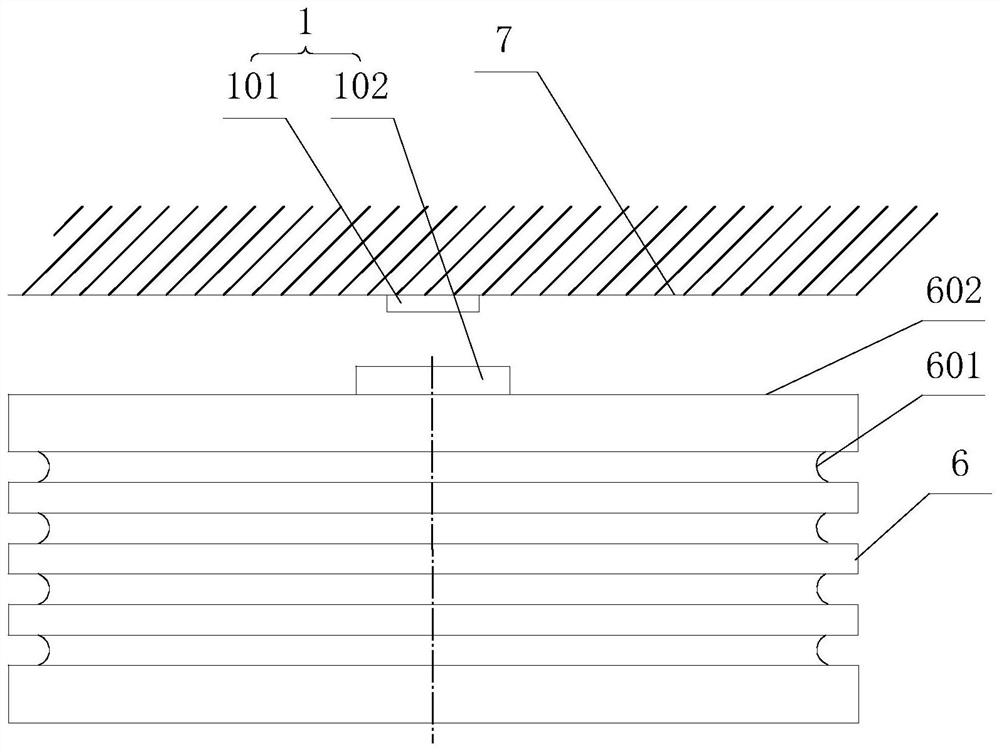

[0072] The deflection detection system 1 includes a laser transceiver 101 and a rotary encoder 102. The rotary encoder 102 is coaxially installed on the rotating shaft of the traction sheave 6 for detecting the cycle and angle of the traction sheave. The output end of rotary encoder 102 is connected with the input end of control system 5; Described laser transceiver 101 is fixed on the wall 7 opposite with traction sheave 6, and laser transceiver 101 signal input end, signal output end are respectively connected with The control system 5 is connected.

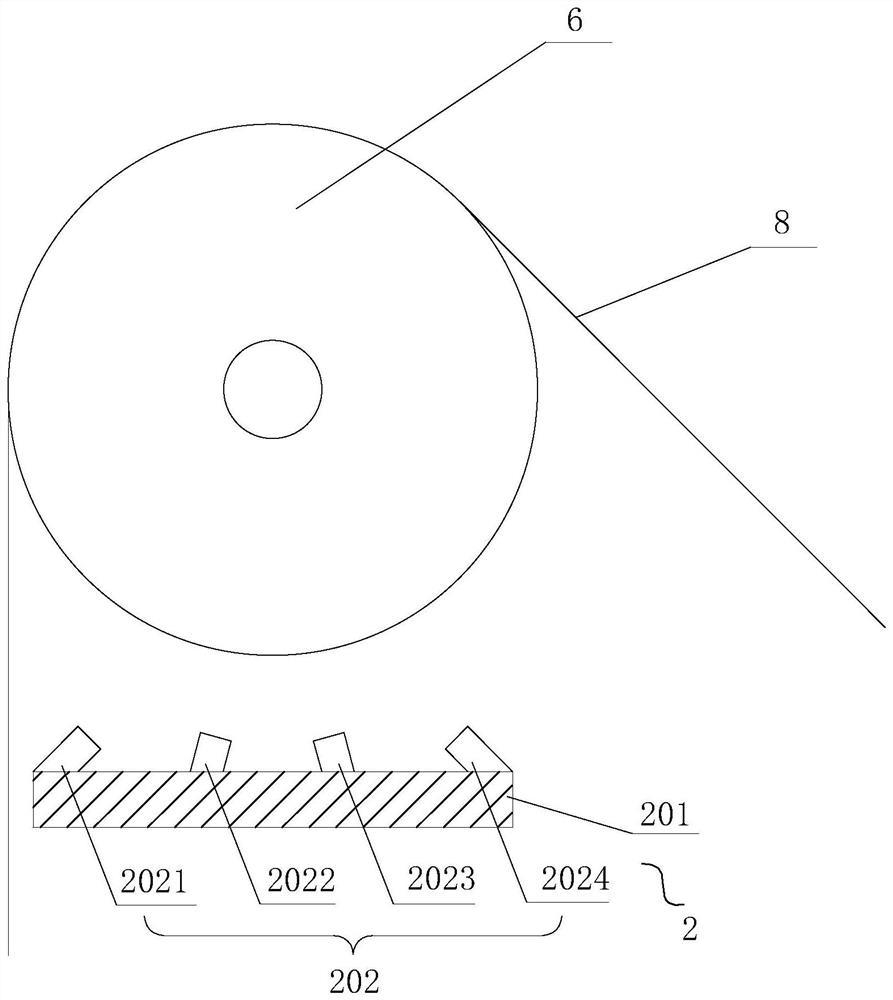

[0073] The wear detection system 2 includes a fixed bracket 201, four ultrasonic probes 202 respectively fixed on the fixed bracket 201...

Embodiment 2

[0078] A traction sheave state monitoring and early warning method based on an algorithm model, the method includes traction sheave deflection monitoring and early warning, traction sheave wear, internal cracks and positioning monitoring and early warning; wherein:

[0079] The traction sheave deflection monitoring and early warning includes the following steps:

[0080] A1. Turn on the elevator traction sheave status monitoring and early warning system based on the algorithm model, and turn on the laser transceiver;

[0081] A2. Run the traction wheel for an initial cycle for the first time, calculate and record the initial distance from the end face A602 of the traction wheel 6 facing the wall 7 to the laser transceiver;

[0082] A3. When monitoring the operation of the traction sheave, collect the whole monitoring data A within one operation cycle, and calculate and save the monitoring distance value from the end face A of the traction sheave to the laser transceiver;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com