Preparation method of ultralow-permeability agent for water-based drilling fluid

A technology of water-based drilling fluid and penetrant, which is applied in the field of oil drilling, can solve the problems of weak pressure bearing capacity and insufficient plugging performance, and achieve the effect of improving plugging capacity, reasonable matching, and solving serious viscosity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

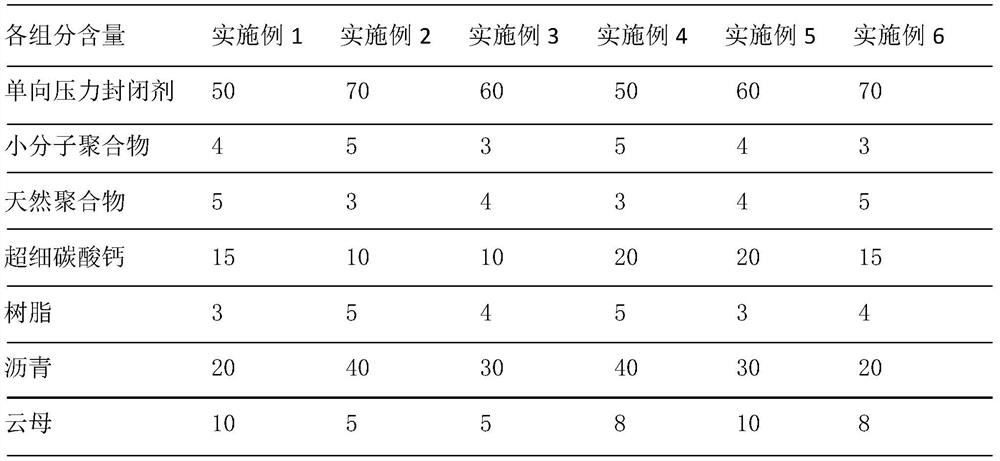

[0029] The components of the added raw materials are as described in Table 1, and the specific steps are: 1) adding 50 parts by weight of a one-way pressure sealing agent to the reactor; 2) adding 4 parts by weight of a low-molecular polymer Mixing and stirring in the reactor; 3) Adding 5 parts by weight of natural polymer into the reactor and mixing and stirring; 4) Adding 15 parts by weight of superfine calcium carbonate and mixing and stirring; 5) Adding 3 parts by weight of mixing and stirring the resin; 6) adding 20 parts by weight of asphalt into the reactor and mixing and stirring; 7) adding 10 parts by weight of mica into the reactor and mixing and stirring; 8) mixing and stirring evenly, discharging and bagging.

Embodiment 2

[0031] The components of the raw materials added are as described in Table 1, and the specific steps are: 1) adding 70 parts by weight of the unidirectional pressure sealing agent to the reactor; 2) adding 5 parts by weight of the low-molecular polymer Mixing and stirring in the reactor; 3) Adding 3 parts by weight of natural polymer into the reactor and mixing and stirring; 4) Adding 10 parts by weight of superfine calcium carbonate and mixing and stirring; 5) Adding 5 parts by weight of mixing and stirring the resin; 6) adding 40 parts by weight of asphalt into the reactor and mixing and stirring; 7) adding 5 parts by weight of mica into the reactor and mixing and stirring; 8) mixing and stirring evenly, discharging and bagging.

Embodiment 3

[0033] The components of the added raw materials are as described in Table 1, and the specific steps are: 1) adding 60 parts by weight of a one-way pressure sealing agent to the reactor; 2) adding 3 parts by weight of a low-molecular polymer Mixing and stirring in the reactor; 3) Adding 4 parts by weight of natural polymer into the reactor and mixing and stirring; 4) Adding 10 parts by weight of superfine calcium carbonate and mixing and stirring; 5) Adding 4 parts by weight of mixing and stirring the resin; 6) adding 30 parts by weight of asphalt into the reactor and mixing and stirring; 7) adding 5 parts by weight of mica into the reactor and mixing and stirring; 8) mixing and stirring evenly, discharging and bagging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com