Composite plugging material for well drilling and application thereof

A plugging material and technology for drilling, which is applied in drilling compositions, earthwork drilling, wellbore/well components, etc., and can solve problems such as back-spitting, back-feeding at plugging parts, and insufficient strength of plugging materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

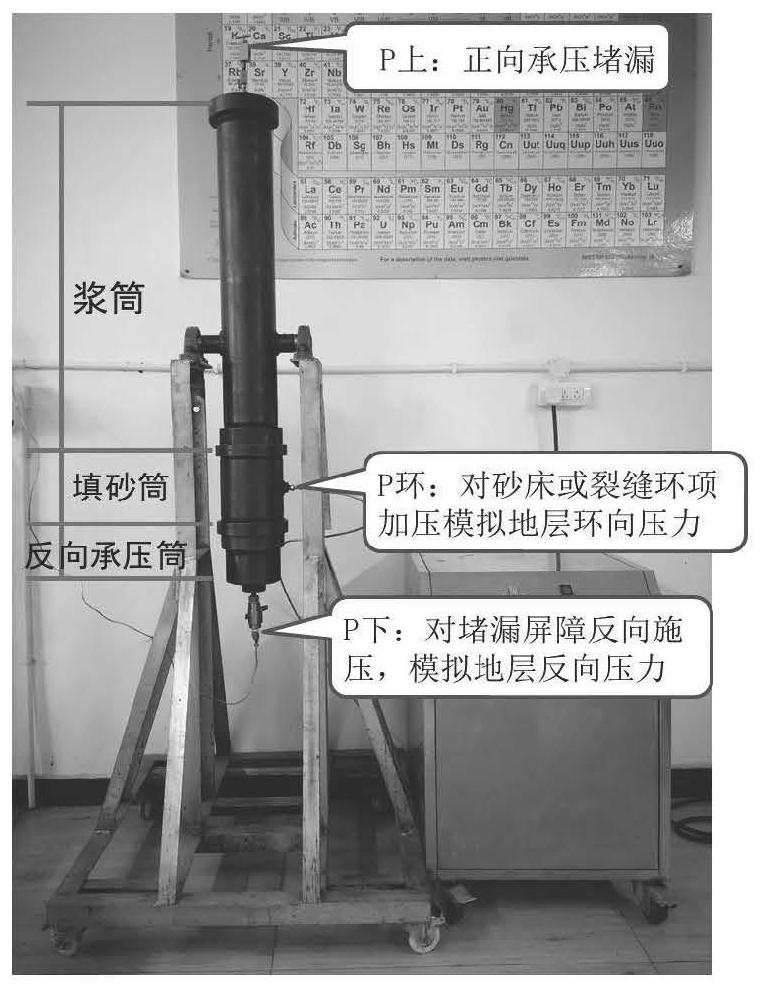

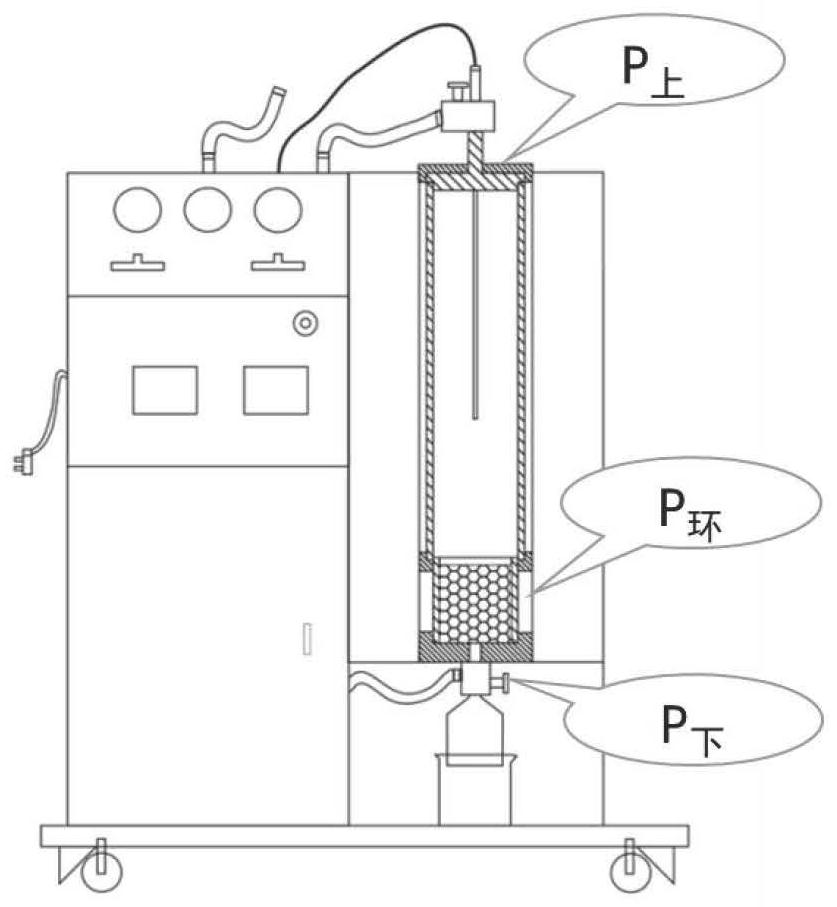

Image

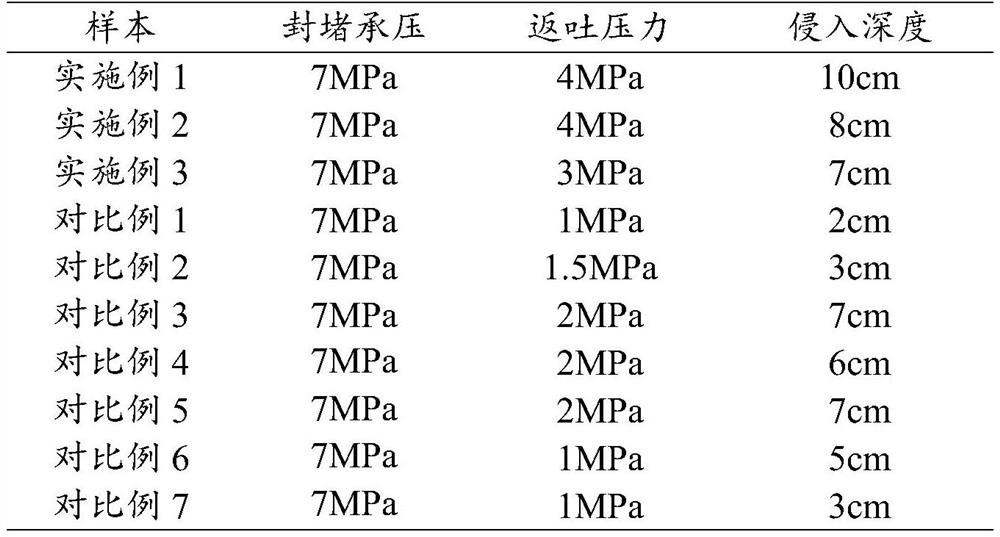

Examples

preparation example Construction

[0027] The present invention does not specifically limit the preparation method of the composite plugging material for well drilling, and the preparation method of the mixture well known to those skilled in the art can be used.

[0028] The present invention also provides the application of the composite plugging material for drilling described in the above technical solution in plugging of wells. The added amount of the composite plugging material for drilling is 3-6% of the total weight of the drilling fluid.

[0029] In the present invention, the drilling fluid is preferably water-based drilling fluid or oil-based drilling fluid.

[0030] In the present invention, the composite plugging material for drilling is preferably used in combination with other plugging agents, such as inducer particles and plugging slurry; The dosage ratio of the agent particles and the plugging slurry is not specifically limited, and those skilled in the art can choose according to the actual situ...

Embodiment 1

[0034] 1 part of carbon fiber with a length of 2mm, inorganic silicon material (10 parts of mica flakes with a particle size of 10-20 mesh, 20 parts of quartz stone with a particle size of 20-40 mesh, 20 parts of wollastonite with a particle size of 20-40 mesh) 50 35 parts, 35 parts of elastic graphene (particle size is 20~60 meshes; rebound rate is 85% after 30MPa compression), 14 parts of tough material (10 parts of styrene-butadiene rubber, 4 parts of silicon rubber), stirring under normal temperature and pressure Evenly, the composite plugging material for drilling is obtained.

[0035] Apply a pressure of 30MPa-0.5h to the composite plugging material for drilling, and the original volume is 36cm 3 , the volume after pressurization is 26.96cm 3 , the volume after depressurization is 32.15cm 3 , the volume change is 5.19cm 3 , indicating that the composite plugging material for drilling obtained in this example has not been greatly damaged under high-pressure loads, has ...

Embodiment 2

[0038] 2 parts of carbon fiber with a length of 2mm, inorganic silicon material (10 parts of mica flakes with a particle size of 10-20 mesh, 25 parts of quartz stone with a particle size of 20-40 mesh, 25 parts of wollastonite with a particle size of 20-40 mesh) 60 Parts, 25 parts of elastic graphite (20-60 meshes in particle size; 85% rebound rate after 30MPa compression), 13 parts of tough material (9 parts of styrene-butadiene rubber, 4 parts of silicon rubber), stirred evenly under normal temperature and pressure , to obtain a composite plugging material for drilling.

[0039]Apply a pressure of 30MPa-0.5h to the composite plugging material for drilling, and the original volume is 36cm 3 , the volume after pressurization is 30.67cm 3 , the volume after depressurization is 33.26cm 3 , the volume change is 2.59cm 3 , indicating that the composite plugging material for drilling obtained in this example has not been greatly damaged under high-pressure loads, has strong elas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com